Electronic paste refers to a new type of functional material developed since the 1960s. It integrates metallurgy, chemical engineering, and electronics technologies. Known for high quality, efficiency, advanced technology, and wide applications, these pastes are crucial in the information and electronics industries. They are essential for hybrid integrated circuits, sensitive components, surface mount technology, resistor networks, displays, and various discrete electronic components. A key element in the performance of electronic pastes is the use of fine metal powders. These powders enhance conductivity and other electrical properties. As a result, they are indispensable for modern electronic applications.

They can be made into thick-film integrated circuits, resistors, resistor networks, capacitors, conductive inks, and solar cell electrodes. They can also be used in LED cold light sources, printed and high-resolution conductors, membrane switches/flexible circuits, conductive adhesives, sensitive components, and other electronic components. They are widely used in a wide range of fields, including aviation, aerospace, computers, measurement and control systems, communications equipment, pharmaceutical devices, the automotive industry, sensors, high-temperature integrated circuits, and consumer electronics.

Fine Metal Powders

Fine metal powders refer to powders with particle sizes between 0.1 and 10 μm. They have a large specific surface area, strong surface activity, low sintering temperatures, and good conductivity and thermal conductivity. These powders are used in electronic pastes, lubricants, catalysts, pharmaceutical, and biological fields. They have become an important topic in the research and development of special functional materials. In recent years, with the rapid development of the electronics industry, the use of fine metal powders in conductive pastes has become a hot research and development topic in the industry.

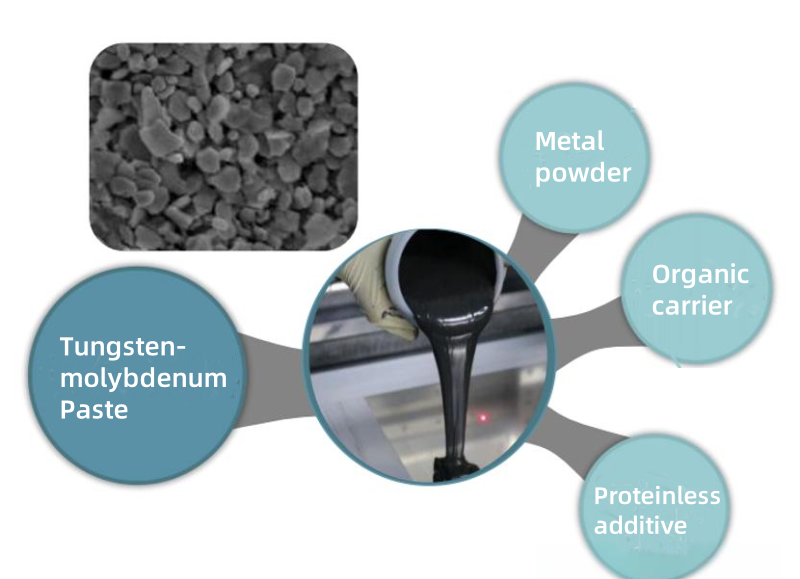

Components of Electronic Paste

Electronic paste is mainly composed of three components: the conductive phase, the binder phase, and the organic carrier. The conductive phase, also called the functional phase, determines the electrical properties of the paste and affects the physical and mechanical properties of the cured film. The conductive phases in electronic paste include carbon, metal, and metal oxides. Common metallic conductive phases include silver, nickel, copper, aluminum, and alloys. The conductive phase significantly influences the performance of the paste, especially in terms of content, morphology, particle size, and surface properties.

Requirements for Conductive Metal Powders

To meet the needs of electronic paste applications, the following requirements are placed on the metallic powder used for the conductive phase: high purity, good conductivity, small particle size, narrow particle size distribution, regular morphology (spherical or flaky), surface oxidation resistance, and compatibility with the paste. The spherical powder preparation techniques mainly include physical vapor deposition (PVD), ultra-high-pressure water atomization, and chemical reduction. The preparation techniques for flaky powders mainly include mechanical crushing and chemical reduction.

Post-Processing Techniques for Metal Powders

The prepared powders also need post-processing techniques, mainly involving control over powder particle size and surface oxidation resistance treatment. After collection, the powders become raw powders. These raw powders are classified into different grades to form graded powder products. Unlike conventional powders, ultrafine metal powders require high precision during classification. The surface oxidation resistance of the metal powders is achieved through surface modification of the metal. Surface transformation techniques, which use physical and chemical methods to alter the composition and structure of the material, are common. These include treatments with surfactants, metal coatings, coupling agents, polymer coatings, and phosphating.

Future Outlook

Because China started late in the field of electronic paste and fine metal powders, it initially faced limitations in hardware and software. However, after nearly 30 years of development, China is now in a period of transition from OEM to technological innovation. The industry is undergoing a comprehensive transformation and rapid development.

Currently, domestic companies are continually developing technologies and equipment for the preparation of spherical and flaky fine metal powders. They are exploring new powder processing technologies, and the application fields are advancing from mid-to-low end to high-end. As the methods for preparing fine metal powders and powder processing equipment continue to improve and upgrade, powder processing technologies are constantly innovating. The performance of the powders will improve, and their application fields and ranges will continue to expand. In the future, the market share and international competitiveness of domestic electronic pastes and fine metal powder materials will continue to grow.

Epic Powder

With the growing demand for high-performance electronic pastes, the role of fine metal powders has become increasingly significant. Epic Powder, with its advanced grinding equipment, plays a crucial part in producing these fine metal powders. By utilizing cutting-edge technology in ball mills, air classifiers, and surface modification systems, Epic Powder ensures the production of high-quality, precise metal powders that meet the stringent requirements of the electronics industry. As the market for electronic materials continues to expand, Epic Powder’s expertise in powder processing will be key in advancing the performance and application of electronic pastes.