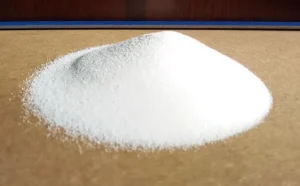

How do calcium carbonate performance parameters affect the plastic filler-modified masterbatch?

Calcium carbonate is the first choice of filler in plastic industry, widely used in plastic film, profiles, tubes, plastic knitting and artificial leather and other