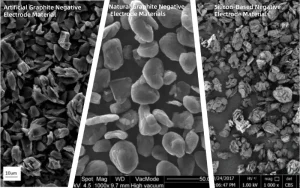

Analysis of the Production Process of Negative Electrode Materials

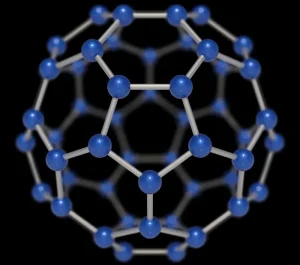

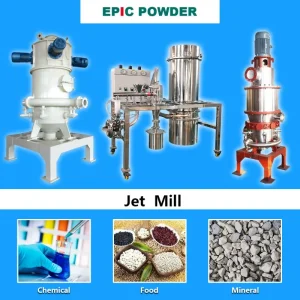

The main types of lithium battery negative electrode materials include graphite-based materials (such as artificial graphite and natural graphite) and non-graphite-based materials (such as silicon-based