The Application of Silicon-Carbon Anode Materials in the Lightweight Design of Consumer Electronics.

In today’s consumer electronics market, there is an increasing demand from consumers for lightweight and long-lasting products. From smartphones to wearable devices, products that are both slim and portable with long battery life are highly favored. The emergence of silicon-carbon anode materials has brought new hope to meet this demand and is gradually becoming a […]

Do You Know the 8 Concepts of Bentonite?

Bentonite is an important natural mineral resource. It is widely used in many industrial fields such as petroleum drilling, casting, environmental protection, agriculture, and chemical processing. This is due to its unique swelling properties, adsorption capacity, and multifunctionality. The main component of bentonite is montmorillonite. However, bentonite can be classified into several types. These types […]

How do Surfactants Affect Powder Agglomeration?

Surfactants significantly affect the agglomeration behavior of powder. They change the interfacial properties, force balance, and medium environment of powder particles. The specific mechanism can be divided into five aspects: Adsorption Modification and Surface Energy Reduction Surfactants adsorb onto powder surfaces. This lowers surface energy and suppresses powder agglomeration. The mechanisms include: Hydrophobic Group Anchoring: […]

High Whiteness Negative Ion Powder Preparation Technology

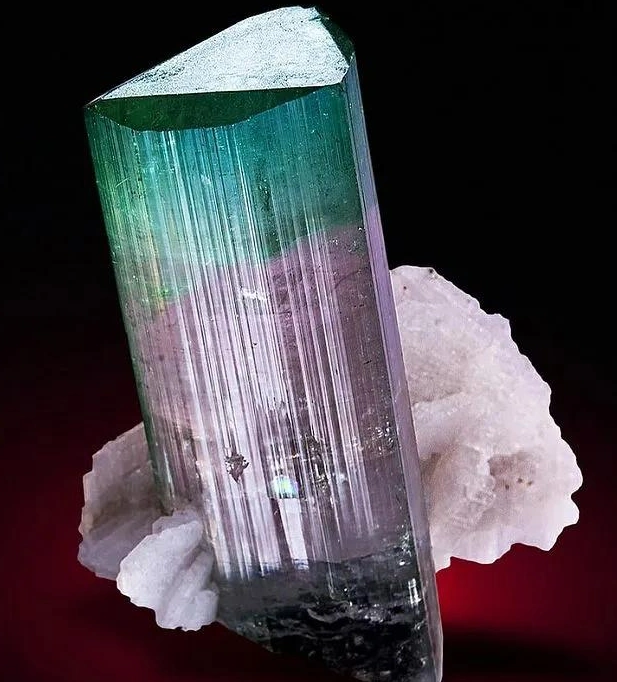

Tourmaline is a silicate mineral with a complex ring structure made of sodium, magnesium, iron, aluminum, and lithium, and is characterized by boron. It has good thermoelectric and piezoelectric effects. It also releases negative ions, radiates far infrared rays, and possesses antibacterial and deodorizing functions. These properties are beneficial to both humans and the environment. […]

How to Choose the Right Quartz Sand for Different Industries ?

Quartz sand is an important basic non-metallic mineral resource, widely used in fields such as glass manufacturing, mechanical casting, electronics, metallurgy, refractory materials, chemicals, and ceramics. Customers often ask which products their quartz ore is suitable for and which industries it can be applied to. Based on the silica (SiO2) content, a preliminary judgment can […]

Preparation of Silicon-carbon Negative Electrode Materials by CVD Method

Common methods for preparing silicon-carbon negative electrode materials include mechanical ball mill, spray drying, chemical vapor deposition (CVD), etc. Mechanical ball mill crushes bulk materials into fine particles by colliding with rotating balls. The process is simple and the cost is low, but the particle agglomeration phenomenon is serious. In addition, excessive grinding will destroy […]

Ultrafine Powder Characterization, Which Methods are Most Commonly Used?

Ultrafine powder (also known as ultrafine powder) usually refers to powder with a particle size below 1250 mesh (10μm). It is subdivided into micron powder, submicron powder and nano powder. When solid matter is crushed to micron or even nanometer scale, its physical and chemical properties will change significantly. This makes ultrafine powder a hot […]

Talcum Powder in Plastic Modification

In today’s plastics industry, modified plastics have attracted much attention for their excellent performance and wide application fields. Talcum powder, as an important and widely used inorganic mineral filler, plays a vital role in plastic modification. Talcum Powder can not only effectively improve the physical properties of plastic products, but also reduce their production costs […]

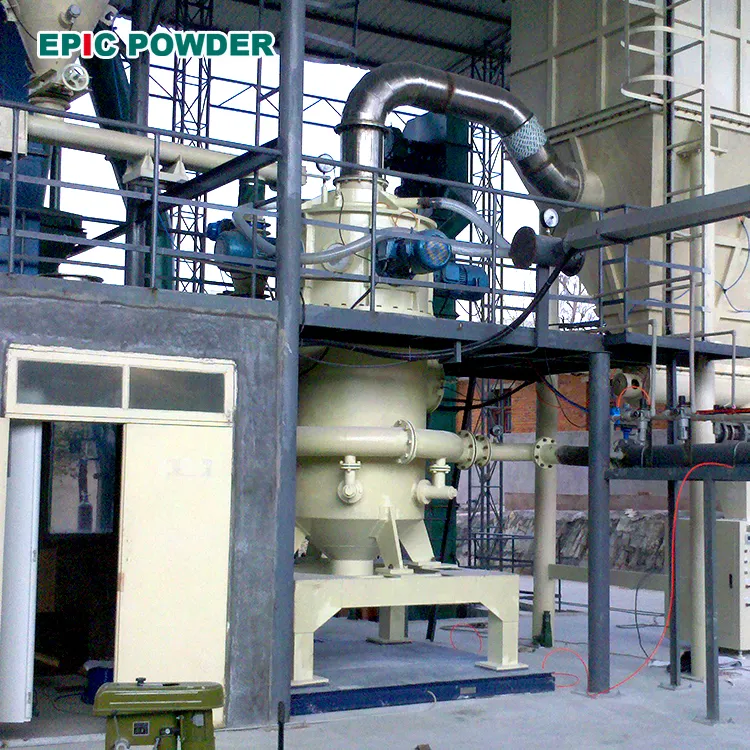

Powder Processing Technology Pushes the Boundaries of Robot Performance

In modern manufacturing, the importance of powder materials is becoming increasingly prominent. Especially in the field of robot manufacturing, powder materials account for more than 65% of the weight of the robot, such as metal powder, ceramic powder and composite powder. With the continuous advancement of technology, the precision of powder processing has also achieved […]