What Ceramic Materials are Needed to Produce a Lithium Battery?

With the continuous development of advanced technology, advanced ceramic powders and products have become key and bottleneck materials in certain high-tech fields. In the lithium

Powerful vortex flow field, instantly grinding and coating

The tapered rotor and stator are adopted, and the gap between the rotor and the stator can be adjusted; the powerful vortex flow field, the linear speed of the rotor can reach 120 m/s, which is especially suitable for the dispersion, reduction and crushing of agglomerated materials. The material is impacted, sheared and rubbed at high speed between the rotor and the stator to complete the grinding and coating process.

This continuous powder surface coating system is designed on the base of German know how with Chinese equipment, and can be used for coating of various powders like calcium carbonate (GCC, PCC), kaolin, talc, mica, graphite, barium sulfate, white carbon black, magnesium hydrate, zinc oxide, aluminum oxide, and is suitable for a variety of solid/liquid coating agents, like aluminate coupling agent, titanate coupling agent, silane coupling agent and stearic acid. Coating machine consists of three units of mixing rooms. High-speed rotation creates great vortex flow inside these special-shaped rooms. Powder and coating agent are mixed in the high-speed gas-solid vortex flows. Coating machine with both surface coating and particle dispersing functions is suitable for various powders with different fineness, and has a unique coating effect for the materials with small apparent specific gravity and high volume to weight ratio. Automatic temperature control system ensures stable high temperature for coating agent melting into liquid and mixing with uncoated powder. Heating and cooling of powder and coating agent are completed in one machine, which does not need independent cooling system. High utilization ratio of coating agent, high powder-coated rate, high activation grade, low energy consumption, and very few agglomerates in final coated product. The whole system is operated under negative pressure, no dust emission, and low labor intensity.

| Model | 300 | 500 | 750 | 1000 | 1250 |

|---|---|---|---|---|---|

| Speed(m/s) | 100-120 | 100-120 | 100-120 | 100-120 | 100-120 |

| Motor Power(kw) | 22 | 45 | 75 | 110 | 132 |

| Blade(layer) | 4 | 4 | 6 | 6 | 6 |

| Fineness(mesh) | 50-2500 | 50-2500 | 50-2500 | 50-2500 | 50-2500 |

Note: The production capacity is closely related to the particle size, specific gravity, hardness, moisture and other indicators of the raw materials. The above is only for selection reference.

With the continuous development of advanced technology, advanced ceramic powders and products have become key and bottleneck materials in certain high-tech fields. In the lithium

Why Choose Biomass as a Precursor? The shift toward Biomass-Derived Porous Carbon represents a critical evolution in materials science, moving away from non-renewable fossil sources

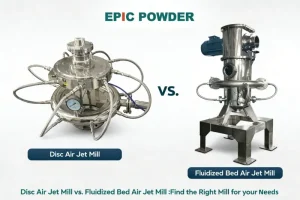

Conceptual Breakdown of Fluidized Bed Jet Mill vs. Disc Jet Mill In the realm of ultrafine powder processing, jet milling stands as a pivotal technology.

Understanding Petroleum Coke Characteristics Petroleum coke (petcoke) is a carbon-rich solid derived from the oil refining process. It features a high carbon content, low ash,

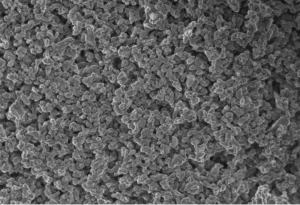

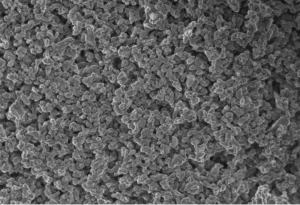

The Science Behind Particle Size and Morphology In my 20+ years of experience with powder processing, I’ve seen firsthand that raw chemical composition is only

In the production of lithium-ion batteries, the performance of cathode materials—such as lithium cobalt oxide (LCO), nickel–cobalt–manganese oxides (NCM), and lithium iron phosphate (LFP)—directly affects

Talc is unique among non-metallic minerals. It is the softest mineral on earth with a Mohs hardness of 1, but its true industrial value lies

Silicon–carbon (Si–C) anodes materials are regarded as one of the core enabling technologies for next-generation high-energy-density lithium-ion batteries. They are designed to overcome the intrinsic

WhatsApp us

Please fill in the form below.

Our experts will contact you within 6 hours to discuss your needs for machine and processes.