Calcium carbonate is an inorganic compound with the chemical formula CaCO₃ and is the main component of limestone, marble, etc. Calcium carbonate is usually white crystals, odorless, essentially insoluble in water, and reacts readily with acids to release carbon dioxide. It is one of the common substances found on earth within rocks such as aragonite, calcite, chalk, limestone, marble, travertine, etc. It is also a major component of the bones or shells of some animals. Calcium carbonate is also an important building material with various industrial uses.

Physical Properties of Calcium Carbonate

Calcium carbonate is a white micro-fine crystalline powder, tasteless and odorless. It has two forms: amorphous and crystalline. Crystalline can be divided into rhombohedral and hexagonal crystal systems (anhydrous calcium carbonate is colorless rhombohedral crystals, hexahydrate calcium carbonate is colorless monoclinic crystals), columnar or rhombic, density 2.93g/cm3. melting point 1339 ℃ (825-896.6 ℃ has been decomposed), the melting point of 1289 ℃ under 10.7MPa. Almost insoluble in water, soluble in water containing ammonium salt or iron trioxide, and insoluble in alcohol.

Calcium Carbonate Structure

The crystal structure is an orthorhombic crystal system. Each calcium carbonate molecule consists of one carbon atom and three oxygen atoms, where each oxygen atom is attached to a calcium ion. Calcium carbonate consists of calcium ions forming ionic bonds with carbonate ions, and carbonate internally consists of carbon-oxygen covalent bonds. Among them, carbonate belongs to sp2 hybridization, the central carbon atom has three orbitals and a p-orbital, according to the VSEPR model, belongs to the AY3-type molecule, and its VSEPR ideal model is a planar triangle, and there are 3 C-O bonds in the molecule in the form of planar triangles; in addition, it also has a 4-orbital, 6-electron p-p large bond. In crystals, calcium carbonate molecules are arranged in layers parallel to the a- and c-axes. Coplanar oxygen atoms interconnect these layers and form a three-dimensional mesh. This structure gives calcium carbonate high stability and hardness.

Calcium carbonate chemical properties

- Calcium carbonate decomposes into calcium oxide and carbon dioxide at 825-896.6 °C. (Industrial production of CO₂):

- Calcium carbonate will and dilute acid (such as acetic acid, hydrochloric acid, dilute nitric acid, etc.) bubble boiling and dissolve. The reaction also releases carbon dioxide in an exothermic reaction. For example, and dilute hydrochloric acid reaction to produce calcium chloride, water, and carbon dioxide (laboratory production of CO₂):

- Water mixed with CaCO3 passes through excess carbon dioxide to form a calcium bicarbonate solution. Calcium carbonate reacts with carbonic acid (rainwater) to produce calcium bicarbonate. Pass CO2 into turbid lime water, and the residue disappears. The principle of these phenomena is:

- Anhydrous calcium carbonate (white, odorless, non-toxic powdery substance, light calcium carbonate) is transformed into calcite (tripartite crystal system, heavy calcium carbonate) when heated to 1000K

According to the different production methods of calcium carbonate, calcium carbonate can be divided into heavy calcium carbonate, light calcium carbonate, colloidal calcium carbonate, and crystalline calcium carbonate. According to the size of the average particle size (d) of calcium carbonate powder, calcium carbonate can be divided into particulate calcium carbonate (d>5μm), micronized calcium carbonate (1-5μm), microfine calcium carbonate (0.1-1μm), ultrafine calcium carbonate (0.02-0.1μm) ultrafine calcium carbonate (d ≤ 0.02μm). According to whether the arrangement of atoms and ions composing calcium carbonate is regular or not, calcium carbonate can be divided into crystalline calcium carbonate and amorphous calcium carbonate. In addition, there are nano calcium carbonate, etc.

Calcium carbonate classification

Heavy Calcium Carbonate

Heavy calcium carbonate (bicarbonate) is produced by directly crushing natural calcite, limestone, chalk, shells, etc., using mechanical methods (with Raymond mills or other high-pressure mills).

Light Calcium Carbonate

Light calcium carbonate (commonly known as light calcium), also known as precipitated calcium carbonate, is calcined limestone and other raw materials to generate lime (the main component of calcium oxide) and carbon dioxide, and then water to digest the lime to generate milk of lime (the main component of calcium hydroxide), and then carbon dioxide carbonation of the milk of lime to generate calcium carbonate precipitation, and finally by dehydration, drying and crushing and produced. First sodium carbonate and calcium chloride complex decomposition reaction to generate calcium carbonate sediment, and then by dehydration, drying, and crushing and produced.

Colloidal Calcium Carbonate

Colloidal calcium carbonate, also known as activated calcium carbonate, modified calcium carbonate, surface treatment of calcium carbonate, gelatinous calcium carbonate, or white manhua, referred to as live calcium, is the use of surface modifiers to light calcium carbonate or heavy calcium carbonate surface modification and produced. Because of the surface modifier, modified calcium carbonate generally has a reinforcing effect, that is, the so-called “active”, so it is customary to modify the calcium carbonate, which is called active calcium carbonate.

Properties: Colloidal calcium carbonate is a very fine white powder, odorless, tasteless, the particles are similar to spheres, with a particle size of 0.1um or less, because of a layer of fat soap adsorbed on the surface of the particles, so it has a colloidal activation performance is an excellent white reinforcing filler. Dissolved in water, decomposed by acid, burnt to burnt black, release carbon dioxide and generate calcium oxide. Specific gravity 1.99~2.01.

Crystalline Calcium Carbonate

Calcium hydroxide and hydrochloric acid reaction to generate calcium chloride, activated carbon decolorization, and removal of impurities, so that the calcium chloride in the presence of ammonia carbonated with carbon dioxide that is calcium carbonate, and then after crystallization, separation, washing, dehydration, drying, screening system.

Properties: pure white, hexagonal crystalline powder. Specific volume 1.2~1.4ml/g. Soluble in acid, almost insoluble in water.

Uses: Used in toothpaste, medicine, etc. It can also be used as thermal insulation and other chemical raw materials.

Nano calcium carbonate

Nano calcium carbonate (ultrafine calcium carbonate) particle size between 1-100nm, is a newly developed powder material in the 1980s. It is an excellent inorganic filler. Used in plastics and resin affinity, it can effectively increase or adjust the material rigidity, toughness, and bending strength, and can improve the rheological properties of the plastic processing system, reduce the plasticizing temperature, improve the stability of the product size, heat resistance and surface finish; in the NR, BR, SBR and other rubber systems, easy to mix, dispersed uniformly and can make the rubber soft, but also improve the performance of the extrusion process and the model of fluidity. Rubber products have a smooth surface, large elongation, high tensile strength, small permanent deformation, good bending resistance, tear strength, and other characteristics. Nano-calcium carbonate has a special crystal and surface electronic structure compared to ordinary calcium carbonate. It has excellent quantum size effect and surface effect in the chemical industry, catalysis, optics, magnetism, electricity, and other fields of application. However, calcium carbonate nanoparticles are prone to aggregation and have a hydrophilic and oleophobic surface, which limits their application in organisms.

Calcium carbonate industrial use

Calcium carbonate is the trade name for the extremely versatile and valuable resource limestone as a mineral raw material. Limestone has been widely used in the history of human civilization for its wide distribution in nature and easy accessibility. As an important building material that has a long history of mining, in modern industry, Limestone is the main raw material for the manufacture of cement, lime, and calcium carbide; it is an indispensable frit in the metallurgical industry, high-quality Limestone by ultra-fine grinding, is widely used in paper, rubber, paint, coatings, pharmaceuticals, cosmetics, feed, sealing, bonding, polishing, and other products in the manufacture. According to incomplete statistics, cement production of Limestone and building stone, lime production, metallurgical flux, and ultrafine calcium carbonate consumption of limestone ratio of 1:3. Limestone is a non-renewable resource, with the continuous progress of science and technology and the development of nanotechnology, limestone applications will be further broadened.

For plastics production

Calcium carbonate is widely used in filling polyvinyl chloride (PVC), polyethylene (PE), polypropylene (PP), acrylic butadiene-styrene copolymer (ABS), and other resins. The addition of calcium carbonate has a role in improving certain plastic product properties to expand their applications. In plastics processing, they can reduce resin shrinkage, improve flow patterns, and control viscosity. It can also play the following roles:

(1) Improve the stability of the size of plastic products;

(2) Improve the hardness and rigidity of plastic products;

(3) Improve plastic processing performance;

(4) Improve the heat resistance of plastic products;

(5) Improve the light diffusion of plastic;

(6) Can make the products have some special properties;

(7) Reduce the cost of plastic products.

Used in the food industry

It can be used as an additive in the food industry. For example, it can be used in various feed additives, with a calcium content of more than 55.6 percent and no harmful components. It can be used as a calcium supplement, and the absorption rate can reach 39%, second only to calcium fructate, soluble in gastric acid, and has become the most dosage form and the most used calcium supplement.

Used in the construction industry

It can be used as raw material for plastic factories, rubber factories, paint factories, waterproof material factories, and internal and external wall paintings. It has the characteristics of high purity, high whiteness, non-toxic, non-odor, low fine oil quality, and low hardness. Marble is also an important building material for house construction.

Used in chemical manufacturing

350 mesh to 400 mesh can manufacture fasteners, downpipes, and chemical industries. The whiteness is above 93 degrees. 400 mesh to 600 mesh can be used for toothpaste paste and soap. The whiteness is above 94 degrees. 800 mesh can be used for rubber, cable, and PVC; the whiteness is above 94 degrees.

It can also manufacture raw materials for optical neodymium glass, etc.

For fine ceramic materials

Calcium carbonate prepares high-temperature stable, dielectric, low thermal conductivity, microporous, and highly pure ceramic materials. Examples include white conductors, widely used in preparing spark plugs, and important fine ceramic materials such as semiconductors, alumina, and enamel pigments.

Uses Mineral fillers and abrasives

Calcium carbonate for industrial use is also used as a mineral filler and abrasive. In producing chemical and building materials, calcium carbonate can replace some expensive materials such as white lead ore, talc, and talcum powder. In abrasives, the particle surface of calcium carbonate can interact with the abrasive matrix to enhance the abrasion resistance and grinding efficiency of the abrasive to improve the efficiency and durability of the abrasive.

For nutritional supplements

The main ingredient in most calcium tablets on the market is calcium carbonate. Calcium carbonate needs to be taken with meals. Due to its carbonic acid content, calcium carbonate tends to produce carbon dioxide in an acidic environment. It is unsuitable for people with poor gastric acid secretion or those using gastric acid inhibitors.

Heavy Calcium Carbonate Production Equipment

-

Calcium Carbonate Powder Production Line

-

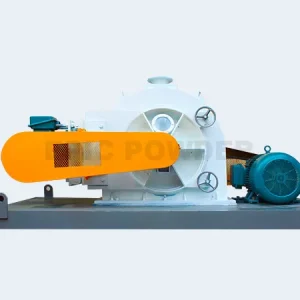

Multi-Rotor Dryer Mill – MRD

-

Horizontal Air Classifier – HTS

-

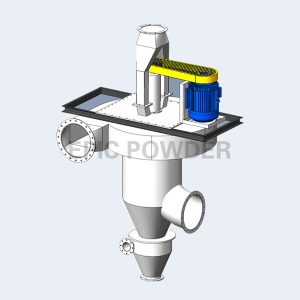

Vertical Air Classifier – ITC

-

Air Classifier – MBS

-

Centrifugal Classifier–CTC

-

Ball Mill Classifier System

-

Roller Mill – SRM

-

Pin mill for powder coating

-

Turbo Mill for Powder Coating

-

Three-roller Mill for Powder Coating