Silica micropowder can be classified based on particle morphology into angular silica micropowder and spherical silica micropowder. Angular silica micropowder is further divided into crystalline silica micropowder and fused silica micropowder based on the raw material type. Additionally, the market includes quasi-spherical silica micropowder, composite silica micropowder, and active silica micropowder. The following sections elaborate on the preparation processes of these silica micropowders, supplemented with the application of jet pulverizer technology:

Crystalline Silica Micropowder

Crystalline silica micropowder uses quartz blocks or sand as raw materials. It undergoes grinding, classification, and impurity removal. Jet pulverizer enables ultra-fine grinding via high-speed airflow. Particles collide and reduce in size. This controls particle size distribution (e.g., D50 at micron level). It enhances purity and reduces impurities. The material meets requirements for copper-clad laminates, epoxy molding compounds, and insulation. Non-contact jet pulverizer minimizes equipment wear. It suits high-hardness quartz processing.

Fused Silica Micropowder

Fused silica micropowder uses fused quartz or glass-like materials. It has lower density (2.2 g/cm³) and dielectric constant. Its thermal expansion coefficient is smaller (0.5×10⁻⁶/K). Jet pulverizer refines particles in grinding. It ensures uniform size distribution. The method avoids metal impurities from mechanical grinding. Airflow speed and classification adjustments control particle size. This meets high-frequency copper-clad laminate filler requirements.

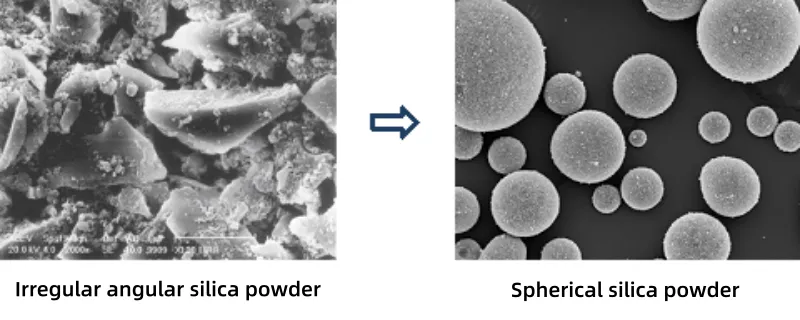

Spherical Silica Micropowder

Spherical silica micropowder starts with angular silica micropowder. It undergoes purification, flame spheroidization, classification, and modification. It offers excellent flowability, low stress, and high packing density. Jet pulverizer grinds raw angular micropowder. It provides uniform particles for spheroidization. This ensures high sphericity post-flame processing. Jet classification selects narrower size distributions. This enhances performance in integrated circuit packaging, aerospace, and ceramics.

Quasi-Spherical Silica Micropowder

Quasi-spherical silica micropowder comes from weathered microcrystalline quartzite. It has high purity, white color, and temperature resistance. It resists corrosion, insulates well, and has low expansion. Jet pulverizer grinds quartzite finely. It optimizes particle size distribution and purity. Low-temperature processing preserves quartzite properties. This suits high-temperature, insulating quasi-spherical micropowder production.

Composite Silica Micropowder

Composite silica micropowder, also known as low-hardness silica micropowder, is made by precisely blending multiple inorganic minerals, melting them into an amorphous glass state, and processing through crushing, magnetic separation, ultra-fine grinding, and classification. With a Mohs hardness of approximately 5.5, the chemical composition is adjusted to reduce silica content and hardness. Jet pulverizer plays a critical role in the ultra-fine grinding stage, using airflow collisions to achieve particle refinement while avoiding metal impurities from mechanical grinding. By adjusting the classification wheel speed, jet pulverizer precisely controls particle size distribution, reducing dust pollution and meeting the requirements for low wear and low dust in drilling processes.

Active Silica Micropowder

Active silica micropowder is produced by adding an appropriate amount of coupling agent to silica micropowder and modifying it at a suitable temperature. It features low viscosity, strong bonding with resins, high peel strength, and excellent high-temperature resistance. Jet pulverizer is used in the initial ultra-fine grinding of silica micropowder, ensuring a high specific surface area and uniform particle size, which enhances reactivity during surface modification. The precise particle size control of jet pulverizer improves the bonding efficiency between the coupling agent and the powder surface, optimizing the dispersibility and drilling performance of active silica micropowder in resin systems.

Conclusion

Jet pulverizer technology is used in ultra-fine grinding and classification. It offers non-contact pulverization, low contamination, and high efficiency. It controls particle size and purity effectively. This meets requirements for crystalline, fused, spherical, quasi-spherical, composite, and active micropowders. In high-precision applications like copper-clad laminates and circuit packaging, jet pulverizer enhances quality and stability.