Ultrafine powder is not only the basic material for the preparation of structural materials, but also has unique functional properties. It is widely used in fine ceramics, electronic components, bioengineering, and new printing materials. It can also be used in many fields such as high-performance refractory materials and fine chemicals. As these industries continue to increase their requirements for powder performance, the position of ultrafine powder classification technology in the entire powder processing technology has become increasingly prominent. It has become a key link in improving product quality and energy efficiency.

The Importance of Ultrafine Powder Classification

During the crushing process, only some particles can reach the target particle size. If this part of qualified powder is not separated in time, it will continue to be crushed together with the unqualified particles. This will not only waste energy, but also may cause excessive crushing of some materials and reduce product quality.

At the same time, as the particle size decreases, the agglomeration tendency between particles increases, and the phenomenon of “crushing and re-aggregation” is prone to occur. It may even lead to deterioration of the crushing effect. Therefore, efficient classification must be carried out in the preparation process of ultrafine powders. On the one hand, the product particle size distribution is controlled within the ideal range. On the other hand, fine powder is separated in time to improve crushing efficiency and reduce energy consumption.

With the increase of powder fineness and the expansion of production capacity, the difficulty of classification is also increasing. The efficient classification of ultrafine powders has become a bottleneck restricting the progress of powder technology. Therefore, classification technology is also regarded as one of the basic core technologies of powder engineering.

Basic Principles of Ultrafine Powder Classification

In a broad sense, powder classification is based on the physical and chemical properties of particles, such as particle size, density, color, shape, chemical composition, magnetism, radioactivity, etc.

In a narrow sense, classification usually refers to the use of particles in a specific medium (such as air or water) to produce different movement behaviors due to different particle sizes under the action of gravity, inertia or centrifugal force.

Thereby achieving effective separation.

Key Technical Issues of Classification

For any classification method, the key to achieve a better classification effect is how to improve the dispersion of the classified materials and choose a suitable classification force field.

After ultrafine processing, the material presents different properties from the original material. First, the specific surface area increases and the surface energy increases. Secondly, the proportion of the number of atoms or ions on the surface is greatly increased, which increases its surface activity. The attraction between particles increases or it is easy to aggregate due to the effect of foreign impurities such as water.

Ultrafine particles are also easy to gather on large particles due to collision absorption during the crushing process or due to static electricity and other forces after crushing. Whether in the air or in the liquid phase, it is easy to generate secondary particles with larger particle sizes. This makes the classification of ultrafine products more difficult than that of ordinary products.

Therefore, the first task of classification is to disperse the particles. Make them in a monodisperse state, thereby improving the dispersibility of the powder. That is, the basis of ultrafine powder lies in the dispersion of powder particles. It can be said that sufficient dispersion can make the classification process more efficient.

EPIC Air Classifier

Horizontal Air Classifier -HTS

Single Classifying Wheel:

- A horizontal mounted staged rotor, linear speed can reach 100m/s;

- The rotor speed can be adjusted by frequency conversion, and the force distribution can be adjusted flexibly;

- Suitable for precise classifying of dry micron material;

- Available D50:1.5-25μm.

Multiple Classifying Wheel:

- The rotor diameter is 315mm-630mm, and 2-6 rotors, which is used for ultra-fine powder classification;

- The classifying wheel increases the classifying space on the top of silo;

- Inverter control, adjustable speed;

- Higher output than single rotor.

Vertical Air Classifier – ITC

- It is very good for apex cutting of ultra-fine products and medium-fine products.

- Applicable to a wide range of particle sizes, the coarsest can reach 200 microns.

- There are different models to meet different output, and the feeding capacity of the largest model can reach 800t/h.

- Wear-resistant design, can handle powder products with extremely high hardness.

- The design of internal air circulation can reduce investment and save floor space.

- It can be combined with a ball mill to form a closed-circuit production system for grinding various materials.

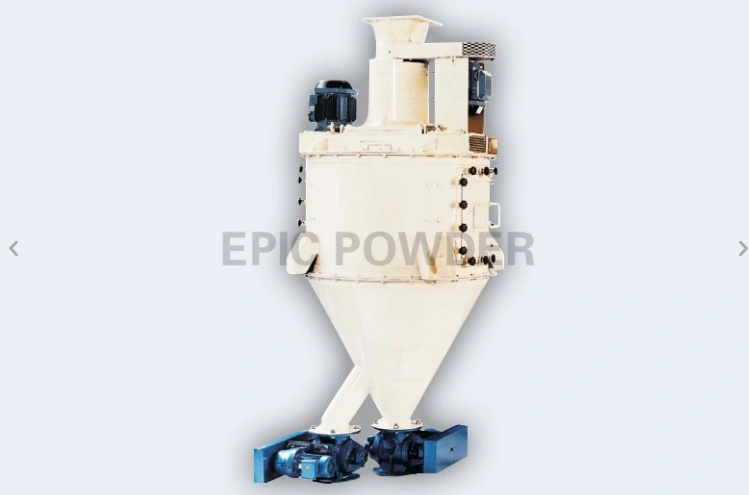

Centrifugal Classifier–CTC

- Classify apex top cutting:d97<32μm.

- Wide range of particle size: 32-250μm.

- The processing capacity range: 1-50t/h.

- The technology comes from Germany, and the design is mature and reliable.

- The equipment has low energy consumption, low investment cost and low maintenance cost.

- No need for peripheral equipment, small footprint.

- Suitable for abrasive, quartz sand, marble and other hard materials.

EPIC Powder

Epic Powder, 20+ years of work experience in the ultrafine powder industry. Actively promote the future development of ultra-fine powder, focusing on crushing, grinding, classifying and modification process of ultra-fine powder. Contact us for a free consultation and customized solutions! Our expert team is dedicated to providing high-quality products and services to maximize the value of your powder processing. Epic Powder—Your Trusted Powder Processing Expert !