What Are the Preparation Processes of Ultrafine Aluminum Hydroxide Powder and Its Surface Modification Mechanisms?

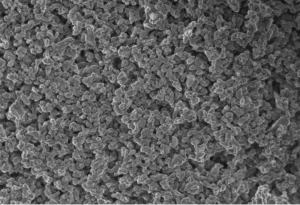

Aluminum hydroxide (ATH) possesses multiple functions, including flame retardancy, smoke suppression, and filling. It does not produce secondary pollution and can generate synergistic flame-retardant effects