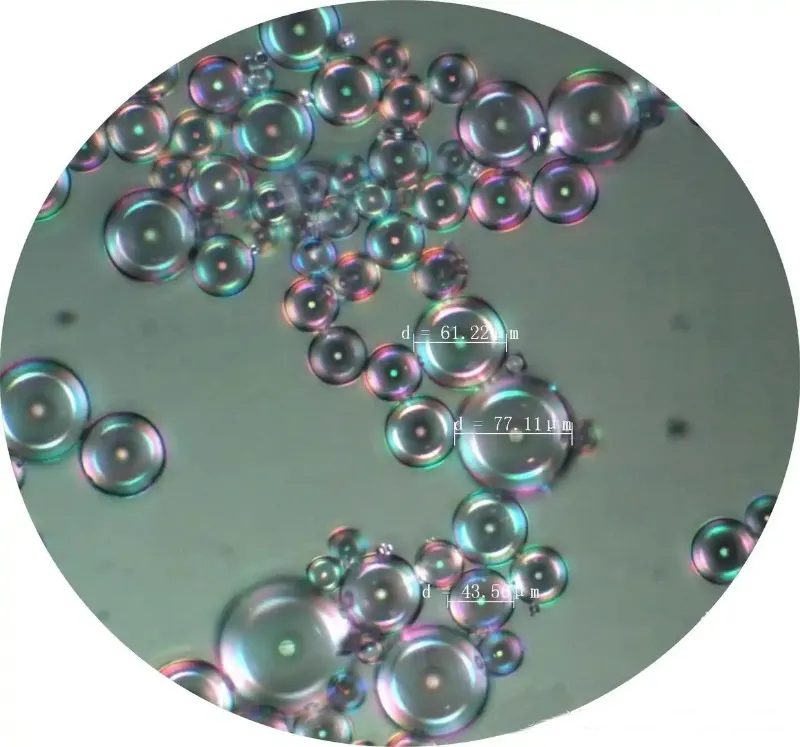

Hollow glass microspheres are micron-level hollow spherical powder materials. They are processed through special techniques. Glass raw materials are transformed into a white, flowable powder. Their particle size ranges from 10 to 250 microns. The wall thickness is 1-2 microns. The interior has a hollow structure. This gives them unique properties such as low density, high strength, low dielectric, low thermal conductivity, corrosion resistance, and electrical insulation. These excellent characteristics make them irreplaceable in various industries.

The upstream of the hollow glass microspheres industry chain mainly involves the mining and processing of glass raw materials such as quartz sand, soda ash, and borax. It also includes the energy supply and equipment manufacturing required for production. The midstream involves the manufacturing process of hollow glass microspheres. It covers key processes such as raw material formulation, high-temperature melting, and balling techniques. By controlling different production parameters, products with various specifications and performance characteristics can be produced. The downstream applications are extensive. These applications cover military and marine, aerospace, 5G photovoltaic, vehicle lightweighting, petrochemical, building energy efficiency, and civilian sectors. The demand from different fields drives midstream companies to continually optimize production processes. This helps improve product quality.

Characteristics

Hollow glass microspheres are small hollow glass spheres. They belong to inorganic non-metallic materials. Their typical particle size ranges from 10 to 180 microns. Their bulk density is 0.1 to 0.25 grams per cubic centimeter. They have the advantages of being lightweight, low thermal conductivity, soundproof, highly dispersible, electrically insulating, and thermally stable. These properties make them a widely developed and highly efficient new lightweight material since 2008.It can be widely used in products that require a specific color appearance.

Lightweight, large volume

The density of hollow glass microspheres is about one-tenth that of traditional fillers. After filling, it significantly reduces the product’s weight. It replaces and saves more resin, thus lowering production costs.

Organic modification (oil affinity)

Hollow glass microspheres are easy to wet and disperse. They can be filled into most thermosetting and thermoplastic resins such as polyester, epoxy, and polyurethane.

High dispersion and good flowability

Due to their small spherical shape, hollow glass microspheres have better flowability compared to plate-like, needle-like, or irregular-shaped fillers. This makes them ideal for molding. Moreover, these small microspheres are isotropic. This prevents issues like inconsistent shrinkage rates at different parts due to orientation. It ensures product dimensional stability without warping.

Thermal insulation, sound insulation, electrical insulation, low water absorption

The hollow interior of glass microspheres contains a thin layer of gas. This provides soundproofing and thermal insulation properties. They are excellent fillers for various thermal insulation and soundproofing products. The thermal insulation properties can also protect products from thermal shock caused by rapid heating and cooling cycles. Their high resistivity and very low water absorption make them ideal for producing cable insulation materials.

Low oil absorption

The spherical shape results in minimal surface area and low oil absorption. This reduces resin consumption during production. It significantly improves operational conditions, increasing production efficiency by 10% to 20%, even with high addition rates.

Applications

Hollow glass microspheres are widely used in artificial agate, marble, fiberglass, bowling balls, high-end thermal insulation coatings, and more. They significantly reduce product weight and improve thermal insulation properties.

They are excellent sensitizers in civilian emulsified explosives. They improve detonation performance and extend storage life. Additionally, hollow glass microspheres are used in automotive body fillers to increase volume, enhance sanding performance, and improve acid and alkali resistance.

Air classifier mill for glass microspheres

Raw Material Processing Requirements:

The production of hollow glass microspheres requires grinding raw materials (such as glass powder) to a specific fineness. The typical fineness is 3-74 μm. The air classifier mill achieves efficient grinding and particle size control through a closed-circuit system. This system uses a grinder and classifier.

Key Equipment: Air classifier mills (for controllable finished particle size) and classification wheel (for 80-300 mesh classification).

Process Advantages: The classification grinding process minimizes over-grinding. This improves the sphericity (≥80%) and uniformity of the hollow glass microspheres.

Epic Powder

Epic Powder’s advanced air classifier mill technology ensures the precise control of hollow glass microsphere particle size (3–74μm), achieving a sphericity rate ≥80% while minimizing over-grinding. This synergy between innovative material design and cutting-edge processing equipment drives the next generation of lightweight, high-performance solutions.