The rapid development of powder coatings has driven the demand for powder fillers. With market drivers in place, research into the application of various powder materials in powder coatings has become increasingly important. The main non-metallic powders used in powder coatings are calcium carbonate, barium sulfate, talcum powder, mica powder, kaolin, silica, and wollastonite.

Fillers in coatings not only reduce costs but also play a significant role in improving the performance of the coatings, such as enhancing wear resistance, scratch resistance, reducing sag during the molten flow of the coating, improving corrosion resistance, and improving moisture resistance.

When selecting fillers for powder coatings, factors such as density, dispersion performance, particle size distribution, and purity must be considered. Generally, the higher the density, the lower the coverage of the powder coating. Larger particles have better dispersion than smaller ones. Fillers should be chemically inert to avoid reacting with certain components in the powder formula, such as pigments. The color of the filler should be as white as possible.

Non-metallic Powders-Calcium Carbonate

Calcium carbonate is available in two types: light calcium carbonate (precipitated calcium carbonate) and heavy calcium carbonate. Regardless of the type or production method, the particle size strongly influences the gloss of the coating. Calcium carbonate is generally not recommended for outdoor use.

Heavy calcium carbonate is primarily used to replace titanium dioxide and colored pigments, as well as partially replace precipitated barium sulfate for corrosion resistance and rust prevention. For indoor architectural paints, heavy calcium carbonate can be used alone or combined with talcum powder. Compared to talcum powder, calcium carbonate reduces the rate of chalking, improves the color retention of light-colored paints, and increases anti-mildew properties. However, its poor acid resistance limits its use in outdoor coatings.

In contrast, light calcium carbonate has a smaller particle size, narrower particle size distribution, higher oil absorption, and greater brightness. It is ideal for applications that require maximum gloss suppression.

Non-metallic Powders-Barium Sulfate

Barium sulfate is available in two forms: natural and synthetic. The natural form is known as barite powder, while the synthetic form is known as precipitated barium sulfate.

In powder coatings, precipitated barium sulfate enhances the flow and gloss retention of the coating, with excellent compatibility with all types of colorants. It helps achieve an ideal coating thickness during the spraying process, with a high powder application rate.

Barite powder is mainly used in industrial primers, automotive intermediate coatings, and high-gloss topcoats that require high film strength, high filling capacity, and high chemical inertness. In latex paints, due to its high refractive index (1.637), fine barite powder acts as a semi-transparent white pigment, partially replacing titanium dioxide in the coating.

Mica Powder in Powder Coatings

Mica powder is a complex silicate material with flaky particles. It has excellent heat and acid-base resistance. Mica powder affects the molten flow properties of powder coatings and is generally used in high-temperature and insulating powder coatings. It can be used as a filler for texture powders.

Among various types of mica, sericite has a chemical structure similar to kaolin, combining features of both mica and clay minerals. Its use in coatings significantly improves the weather resistance, water resistance, adhesion strength, and overall appearance of the film. Additionally, dye particles can easily enter the interlayer of sericite, helping the color remain vivid for longer.

Sericite powder also exhibits anti-algae and mildew resistance, making it an excellent multifunctional filler with a high price-to-performance ratio.

Talcum Powder in Powder Coatings

Talcum powder, also known as hydrated magnesium silicate, is directly crushed from talc ore. The particles have a needle-like crystalline structure, with a slippery feel, soft texture, and low abrasiveness. It has good suspension, dispersion, and thixotropic properties, which greatly influence the molten flow properties of powder coatings. Talcum powder is commonly used in texture powders.

Currently, talcum powder is used in various primers, intermediate coatings, road marking paints, industrial coatings, and both interior and exterior architectural paints. However, it has certain drawbacks. It has a high oil absorption rate, which requires the use of low-oil absorption fillers or barite powder for certain applications. It also has poor wear resistance, requiring additional fillers for applications requiring high wear resistance. Additionally, talcum powder contains impurities that may react with acids (such as acid rain), limiting its use in outdoor coatings that require high weather resistance. It also has a matting effect, so it is generally not used in high-gloss coatings.

Silica in Powder Coatings

Porous quartz is a type of silica system. It is recognized for its safety and is widely used in powder coatings, fireproof coatings, waterproof coatings, and anti-corrosion coatings. Low-cost porous quartz can reduce the cost of powder coatings and also replace barium sulfate to reduce the content of soluble barium, meeting environmental requirements.

Additionally, fumed silica is commonly used as an anti-caking and anti-clumping agent in powder coatings. It is a multifunctional pigment and an excellent rheology control agent for coatings. In liquid coatings, it serves functions such as thickening, thixotropy, anti-sagging, and edge coverage. In solid powder coatings, it enhances the free-flowing properties of the powder, prevents clumping, and promotes fluidization.

Non-metallic Powders-Kaolin

Kaolin can be divided into calcined kaolin and washed kaolin. Generally, calcined kaolin has higher oil absorption, opacity, porosity, hardness, and brightness than washed kaolin.

Kaolin can improve thixotropy and anti-settling properties. Calcined kaolin does not affect the rheological properties of coatings but can have a matting effect, increase opacity, and whiteness, similar to talcum powder.

Kaolin generally has high water absorption, making it unsuitable for enhancing the thixotropy of coatings or for preparing hydrophobic coatings. Its particle size typically ranges from 0.2 to 1 μm. Coarser kaolin has lower water absorption and better matting effects, while kaolin with a particle size of less than 1 μm is used in semi-gloss and interior coatings.

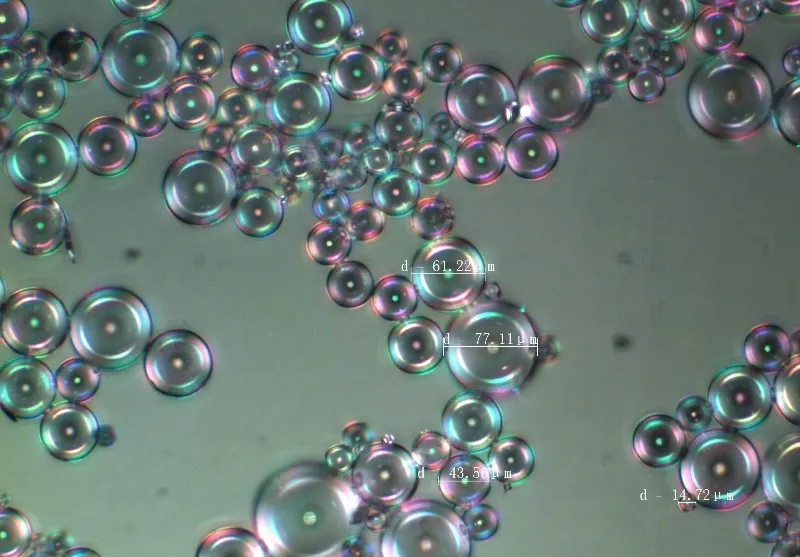

Hollow Glass Microspheres in Powder Coatings

Hollow glass microspheres are tiny, hollow, spherical powders with advantages such as low weight, large volume, low thermal conductivity, high compressive strength, insulation, corrosion resistance, non-toxicity, and good dispersion, flow, and stability.

When applied in powder coatings, hollow glass microspheres serve the following purposes:

- Thermal Insulation and Insulation: Their internal structure is either vacuum or filled with thin gases, which creates a significant density and thermal conductivity difference with epoxy resins. This makes them an excellent filler for high-temperature powder coatings.

- Improving Mechanical Properties: Hollow glass microspheres increase the hardness and stiffness of powder coatings but reduce impact resistance. The extent of impact resistance reduction depends on the surface treatment of the microspheres. Using the correct coupling agent can reduce the negative impact on impact resistance.

- Low Oil Absorption: The oil absorption rate of hollow glass microspheres is low, ranging from 7 mg to 50 mg per 100 g. This reduces the filling amount and lowers overall costs during production.

Wollastonite in Powder Coatings

Wollastonite is primarily composed of calcium metasilicate. It has a density of 2.9 g/cm³, a refractive index of 1.63, and an oil absorption of 30% to 50%. It has a needle-like structure and good brightness.

Powder coatings generally use natural wollastonite powder, which is processed from natural wollastonite. It serves as a body pigment and a partial substitute for white pigments, providing opacity and increasing the volume while reducing coating costs. Due to its excellent conductivity, it is often used in epoxy insulation powder coatings. Wollastonite has a white needle-like structure, which improves the bending and tensile properties of powder coatings.

Epic Powder

As the powder coating industry continues to grow, so does the demand for high-quality, cost-effective fillers. Epic Powder, with its extensive experience in the development of advanced powder processing solutions, is committed to providing the ideal equipment for grinding and dispersing various inorganic non-metallic powders. Whether it’s for enhancing the performance of coatings or achieving precise particle size distributions, Epic Powder’s technologies ensure superior results tailored to meet the evolving demands of the powder coating industry.