An air classifying mill is a type of mechanical impact mill. It uses air to separate and classify particles based on their size, shape, or density. It is commonly used in the pharmaceutical, chemical, and food industries. It is used to produce fine powders.

Definition and Working Principle of Air Classifier Mill:

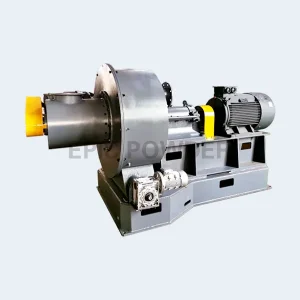

The air classifier mill consists of a grinding chamber and an air classifier. The grinding chamber contains a rotor assembly with hammers. The hammers rotate at high speed, creating a strong air vortex. The particles enter the mill through an inlet and are ground by the rotating hammers. The airflow carries the ground particles to the classifier. They are separated based on their size and density. The fine particles are collected in a cyclone or bag filter. The coarse particles are returned to the grinding chamber for further processing.

Advantages of Air Classifier Mill:

- The air classifier mill offers efficient and precise particle size reduction. It can produce fine powders with a narrow particle size distribution. This allows for better control over the final product quality.

- The air classifier mill can handle a wide range of materials. It can process heat-sensitive and abrasive substances. It can grind, classify, and separate particles in a single operation. This reduces the need for additional equipment.

- The air classifier mill consumes less energy than other grinding mills. The rotor’s high-speed rotation contributes to the efficient grinding process. The air vortex created in the grinding chamber also helps. This results in energy savings.

- Easy Maintenance: The air classifier mill is designed for easy maintenance and cleaning. The grinding chamber and the classifier. They are easily accessed for inspection and cleaning. This reduces downtime and ensures optimal performance.

Disadvantages of air classifying mill:

- The air classifier mill requires a significant initial investment. This is compared to other grinding mills. The cost of the equipment, installation, and maintenance may be higher. This is especially true for small-scale operations.

- The high-speed operation of the air classifier mill can generate noise and dust. This may require additional noise and dust control measures in the production area.

- The air classifier mill can produce fine powders. However, it may have trouble producing extremely coarse or ultra-fine particle sizes. The particle size range may vary. It depends on the specific design and configuration of the mill.

Applications of air classifying mill:

- The air classifier mill is widely used in the pharmaceutical industry. It’s used to produce fine powders. For example, active pharmaceutical ingredients (APIs) and excipients. It is used in making tablets, capsules, and other pharmaceutical forms.

- the air classifier mill is used to grind and classify various chemicals in the chemical industry. This includes pigments, dyes, and catalysts. It allows precise control over particle size and distribution. This ensures consistent product quality.

- The food industry uses the air classifier mill. It grinds and classifies various food ingredients. These include spices, sugar, and starches. It enables the production of fine powders that are used in food processing and flavoring.

- the air classifier mill grinds and classifies cosmetic ingredients in the cosmetics industry. It processes powders for makeup products and skincare formulations. It ensures the uniformity and consistency of the cosmetic powders.

The air classifier mill is versatile and efficient grinding equipment. It offers precise particle size reduction and classification. It has advantages such as efficient operation and easy maintenance. However, it also has disadvantages, such as high initial investment and noise generation. However, its applications in various industries make it a valuable tool for producing fine powders. These industries include pharmaceuticals, chemicals, food, and cosmetics.