How to Achieve Morphology Control of Powder Particles?

Morphology control of powder particles is one of the core technologies in advanced material preparation. It directly determines the packing density, flowability, sintering activity, and

MQP disc jet mill, also known as spiral jet mill, the basic principle is: use the negative pressure generated by compressed air to suck the material in the hopper into the flat grinding chamber; The high-speed airflow (sonic speed or even supersonic speed) collides and crushes each other, and the materials that reach a certain particle size will approach the center of the grinding chamber due to the reduction of centripetal force, and will be discharged from the grinding chamber with the flow of airflow, and then enter the cyclone and dust collector.

Compressed gas is used to pass the feeder ejector to bring the ground raw materials into the grinding chamber, and driven by the high-speed airflow from multiple nozzles, it is sprayed on the grinding wall in a tangential manner to achieve the effect of friction grinding. By adjusting the longitudinal depth of the grinding chamber, adjusting the grinding pressure or feeding speed, the fineness of grinding can be controlled. Compared with the fluidized bed jet mill, the controllability of the pulverization fineness is less.

| parameter/ Model | MQP01 | MQP02 | MQP03 | MQP06 | MQW10 | MQW15 | MQW20 | MQW30 | MQW40 | MQW60 |

|---|---|---|---|---|---|---|---|---|---|---|

| Feeding Size(mm) | < 2 | <2 | <5 | <2 | <3 | <3 | <3 | <3 | <5 | <5 |

| Particle size(D97:μm) | 8~150 | 8~150 | 8~150 | 8~150 | 8~150 | 8~150 | 10~150 | 10~150 | 10~150 | 10~150 |

| Production Capacity(kg/h) | 5~15 | 5~100 | 10~200 | 20~400 | 50~800 | 150~1500 | 300~2000 | 150~1500 | 300~2000 | |

| Air consumption(m³/min) | 1 | 2.5 | 3 | 6 | 10 | 15 | 20 | 30 | 40 | 60 |

| Air pressure(Mpa) | 0.7~0.85 | 0.7~0.85 | 0.7~0.85 | 0.7~0.85 | 0.7~0.85 | 0.7~0.85 | 0.7~0.85 | 0.7~0.85 | 0.7~0.85 | 0.7~0.85 |

| Installed power (kw) | 7.5 | 15~20 | 26~37 | 30~37 | 65~85 | 85~100 | 120~142 | 175~200 | 276~310 | 402~427 |

Note: The production capacity is closely related to the particle size, specific gravity, hardness, moisture and other indicators of the raw materials. The above is only for selection reference.

Morphology control of powder particles is one of the core technologies in advanced material preparation. It directly determines the packing density, flowability, sintering activity, and

Centella asiatica (also known as Gotu Kola) is an important medicinal and edible plant. Its key active compounds — primarily triterpenoids (such as asiaticoside, madecassoside,

Particle classification refers to separating particles of the same material according to differences in physical properties such as particle size, shape, or density. In most

Macro Background: Humanoid Robots Enter the “Lightweight Era” As humanoid robots enter their first year of mass production, the industry is facing unprecedented technological challenges

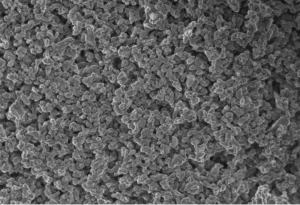

With the continuous development of advanced technology, advanced ceramic powders and products have become key and bottleneck materials in certain high-tech fields. In the lithium

Why Choose Biomass as a Precursor? The shift toward Biomass-Derived Porous Carbon represents a critical evolution in materials science, moving away from non-renewable fossil sources

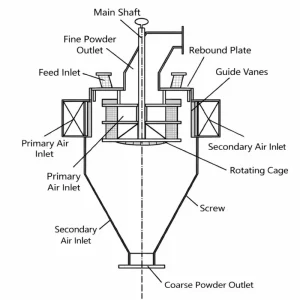

Conceptual Breakdown of Fluidized Bed Jet Mill vs. Disc Jet Mill In the realm of ultrafine powder processing, jet milling stands as a pivotal technology.

Understanding Petroleum Coke Characteristics Petroleum coke (petcoke) is a carbon-rich solid derived from the oil refining process. It features a high carbon content, low ash,

WhatsApp us

Please fill in the form below.

Our experts will contact you within 6 hours to discuss your needs for machine and processes.