What Are the Causes of Low Activity During Slag Powder Grinding and Their Solutions?

1. Causes of Low Activity of Slag Powder Many factors contribute to the low activity of slag powder. A high proportion of crystalline phases and

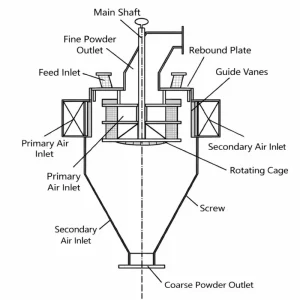

CTC series air classifier is designed under the guidance of our German experts, and it is specially developed for separating powder products between 32-250μm. It does not require any peripheral equipment, such as cyclone collector, bag filter, induced draft fan, etc. Raw material enters the classifier from the top and falls onto the rotating bulk pan. The bulk pan distributes the product in an adjustable airflow created by an internal fan. Fine particles are entrained in the airflow and carried to the outer chamber, while coarse particles fall into the inner chamber. Fine powder products and coarse powder products are discharged from the bottom of the classifier respectively. This process of internal air circulation and self-grading greatly reduces investment, production and maintenance costs. When processing high-hardness materials such as abrasives and quartz, the inlet chute and internal rotating parts can be made of high-hardness materials or lined with high hardness, depending on the situation. In addition, if it is necessary to avoid iron pollution, the interior of the classifier can be lined with alumina ceramic sheets and polyurethane.

CTC series air classifier is designed under the guidance of our German experts, and it is specially developed for separating powder products between 32-250μm. It does not require any peripheral equipment, such as cyclone collector, bag filter, induced draft fan, etc. Raw material enters the classifier from the top and falls onto the rotating bulk pan. The bulk pan distributes the product in an adjustable airflow created by an internal fan. Fine particles are entrained in the airflow and carried to the outer chamber, while coarse particles fall into the inner chamber. Fine powder products and coarse powder products are discharged from the bottom of the classifier respectively. This process of internal air circulation and self-grading greatly reduces investment, production and maintenance costs. When processing high-hardness materials such as abrasives and quartz, the inlet chute and internal rotating parts can be made of high-hardness materials or lined with high hardness, depending on the situation. In addition, if it is necessary to avoid iron pollution, the interior of the classifier can be lined with alumina ceramic sheets and polyurethane.

| Parameter / Model | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 |

|---|---|---|---|---|---|---|---|---|

| Drive power of internal fan(kW) | 5.5 | 7.5 | 11 | 15 | 22 | 30 | 37 | 55-75 |

| Drive power of classifier (kW) | 2.2 | 3.0 | 4.0 | 5.5 | 7.5 | 11 | 15 | 22 |

| Max. classifier speed (rpm) | 800 | 670 | 560 | 475 | 400 | 355 | 315 | 280 |

| Max. feed rate (t/h) | 5 | 8 | 12 | 17 | 24 | 30 | 38 | 48 |

| Fineness D97 (μm) | 32-200 | 32-200 | 32-200 | 32-200 | 40-200 | 40-200 | 45-250 | 50-250 |

Note: The production capacity is closely related to the particle size, specific gravity, hardness, moisture and other indicators of the raw materials. The above is only for selection reference.

1. Causes of Low Activity of Slag Powder Many factors contribute to the low activity of slag powder. A high proportion of crystalline phases and

Aluminum hydroxide (ATH) possesses multiple functions, including flame retardancy, smoke suppression, and filling. It does not produce secondary pollution and can generate synergistic flame-retardant effects

Bentonite is widely acclaimed as the “Universal Clay,” with its core mineral constituent being Montmorillonite. This layered silicate, forged from volcanic ash over millions of

Sodium-ion batteries (SIBs) have attracted significant attention in recent years due to abundant sodium resources, low cost, and advantages in low-temperature performance and safety. However,

Morphology control of powder particles is one of the core technologies in advanced material preparation. It directly determines the packing density, flowability, sintering activity, and

Centella asiatica (also known as Gotu Kola) is an important medicinal and edible plant. Its key active compounds — primarily triterpenoids (such as asiaticoside, madecassoside,

Particle classification refers to separating particles of the same material according to differences in physical properties such as particle size, shape, or density. In most

Macro Background: Humanoid Robots Enter the “Lightweight Era” As humanoid robots enter their first year of mass production, the industry is facing unprecedented technological challenges

WhatsApp us

Please fill in the form below.

Our experts will contact you within 6 hours to discuss your needs for machine and processes.