Calcium carbonate is an important inorganic compound. It is widely used in many industries, including construction, fertilizers, steel, and paints. It is also used in sealants and adhesives. India has rich limestone reserves. Its calcium carbonate industry has grown rapidly. It has huge market potential.

Overview of Calcium Carbonate Resources in India

India has a lot of calcium carbonate. It is mainly in marble, limestone, and chalk. These resources are widely distributed in India. They provide a solid foundation for developing the calcium carbonate industry.

China, the U.S., Brazil, India, and Russia have the richest calcium ore reserves in the world. The US Geological Survey (USGS) released data on calcium ore. By 2022, the world’s proven reserves were about 400 billion tons. India had 8.75% of that, or about 35 billion tons. This is for reference only.

India has marble deposits in several regions. They have high whiteness and good abrasive properties. So, they are very suitable for making calcium carbonate. These marble deposits are the main source of raw materials for the calcium carbonate industry. The international market highly favors them for their high quality.

India’s calcium carbonate resources are diverse and widely distributed. Marble resources are found all over India. Some important geological areas have high-quality marble. It provides raw materials for making calcium carbonate. In addition, India has relatively rich limestone and chalk resources. Their use in calcium carbonate production is low. But, they are important for developing India’s calcium carbonate industry.

The paper industry is the largest consumer of calcium carbonate in India

India has many calcareous marble deposits. They are good abrasives. They can be processed into calcium carbonate products. The abundant limestone reserves provide enough raw materials to make calcium carbonate.

In India, some major calcium carbonate manufacturers have strong production capacity. They are 20microns Ltd, Fimaken India, Gushan Sugar & Chemicals Ltd, Imerys, Vimal Microns Ltd, and Wolkem Ltd. These companies mainly grind marble or limestone into GCC products. They do this to meet the demand of domestic and foreign markets.

In India, calcium carbonate is used mainly in papermaking, plastics, sealants, and rubber. In particular, the papermaking industry is the largest consumer of calcium carbonate. Statistics show that 47% of heavy calcium carbonate in India is used for paper. 40% is used for plastics, sealants, and rubber. The main uses of plastics are in packaging and PVC cables, pipes, and fittings.

Indian calcium carbonate market development drivers

India’s economy and population are growing. This has increased demand for food processing and packaging. It has also boosted the need for calcium carbonate in plastics, paper, coatings, and rubber. Calcium carbonate is a key filler and coating in papermaking. It improves paper quality and cuts costs.

The Indian government has steadily increased its support for the calcium carbonate industry. It has offered tax incentives, improved infrastructure, and other measures to boost development. Also, the government encourages firms to innovate and develop calcium carbonate products. This will boost their value and market edge.

Indian calcium carbonate firms are integrating with the global market. They are using advanced tech and management practices to boost quality and efficiency. India is exporting calcium carbonate products to boost its global market and competitiveness.

Challenges facing the Indian calcium carbonate market

India has abundant limestone. But, mining it is restricted by environmental policies. The Indian calcium carbonate industry must protect the environment and use resources wisely. This is a key challenge.

The Indian calcium carbonate industry lacks high-end tech and R&D. Companies must improve their products to meet the high-end market’s needs.

The influx of domestic and foreign calcium carbonate companies is raising market competition. Indian calcium carbonate firms must innovate and build their brands. This will improve their competitiveness and help them gain market share.

EPIC Powder provides high-quality calcium carbonate powder production process

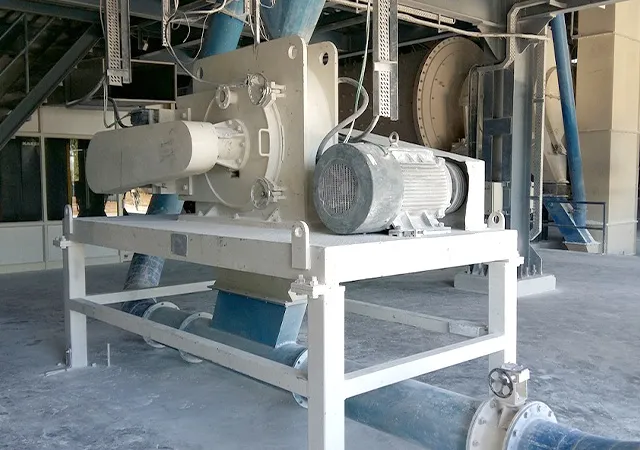

EPIC Powder Machinery helps the development of the Indian calcium carbonate market. We produce a variety of calcium carbonate powder production equipment such as ball mill classification production line, ring roller mill, air classifier, three-roller mill modifier, pin mill modifier, cyclone mill modifier, etc.

Calcium carbonate dry grinding equipment

Calcium carbonate powder air classifier

Calcium carbonate powder coating modification equipment

India’s economy and population are growing. So, the calcium carbonate industry will see great growth. If we explore the Indian calcium carbonate market, there will be unlimited potential. We must also develop the industry sustainably.