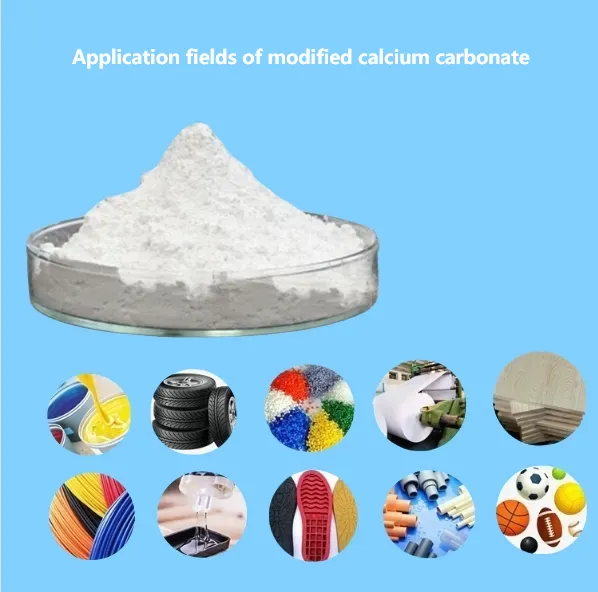

Stearic Acid Surface Modified Calcium Carbonate is widely used in various industries, especially plastics, rubber, coatings, and adhesives. Its primary role is to enhance the dispersion and compatibility of calcium carbonate in composite materials, thereby improving performance. The stearic acid molecule has both hydrophilic and hydrophobic segments. The hydrophilic group interacts physically and chemically with the calcium carbonate surface. Through adsorption and coating, it effectively reduces particle interactions, leading to more uniform dispersion in polymer matrices. Stearic acid surface modified calcium carbonate can be processed using either dry or wet methods. The wet method typically requires the use of stearic acid salts, such as sodium stearate. Both methods have their advantages and disadvantages, making them suitable for different production needs and product characteristics.

Stearic Acid Dry Surface Modified Calcium Carbonate

The process generally involves drying calcium carbonate to remove moisture (if moisture is less than 1%, drying is not necessary). Stearic acid is then added to the surface modification machine for coating. The advantage of this process is its simplicity, ease of operation, and ability to achieve large-scale production quickly. It requires relatively low equipment specifications and works well in scenarios with high production efficiency demands but looser modification precision.

In continuous powder surface modification equipment, materials and stearic acid are continuously fed together. Stearic acid is added as solid powder, typically 0.8%-1.2% of the calcium carbonate weight, depending on particle size or surface area. In continuous production, precise metering and stable material delivery are key for consistent modification effects. Advanced automation systems ensure precise control of material flow and modifier addition, ensuring stable product quality.

In high-speed mixers, horizontal paddle mixers, and other temperature-controlled mixers, surface coating is typically done in batch operation. The pre-measured materials and stearic acid are added and mixed for 15-60 minutes before packaging. Stearic acid usage is typically 0.8%-1.5% of calcium carbonate weight, with reaction temperature around 100°C. This batch operation is slower but more flexible, suitable for small-batch and multi-variety production. In companies that customize products for specific client needs, batch dry modification plays a crucial role.

To improve stearic acid dispersion, it can be diluted with a solvent (e.g., anhydrous ethanol) before modification. Additives like dispersants can reduce agglomeration and improve uniform coating. Coupling agents can enhance the interface bonding between calcium carbonate and polymer matrices, significantly improving composite material performance.

Stearic Acid Wet Surface Modified Calcium Carbonate

Wet modification involves surface treatment of calcium carbonate in an aqueous solution. The process generally starts by saponifying stearic acid, then adding it to the calcium carbonate slurry. After a certain reaction time, filtration and drying are performed. Calcium carbonate dispersion in the liquid phase is easier than in the gas phase.

Additionally, dispersants can be added to improve the dispersion effect, ensuring more uniform interaction between calcium carbonate particles and surface modifier molecules. When calcium carbonate particles adsorb stearic acid salts, surface energy is reduced. Even after filtration and drying, secondary particles are formed with weaker agglomeration, which can be easily re-dispersed with lower shear force.

Wet modification equipment is generally simple, consisting of containers with stirrers and static mixers. Strong agitation improves activation efficiency and shortens reaction time, but it requires higher equipment performance.

Although wet surface modification can be performed at room temperature, longer reaction times are needed. Therefore, heating is generally applied, with modification temperatures around 50-100°C.

Wet surface modification is commonly used for light calcium carbonate and ultrafine heavy calcium carbonate produced by wet grinding.

Conclusion

Stearic acid is a versatile and cost-effective surface modifier for calcium carbonate. Both dry and wet modification methods have their unique advantages and are chosen based on the specific production needs. Dry modification offers simplicity and speed, while wet modification ensures better dispersion and uniform interaction with calcium carbonate particles. By carefully selecting the appropriate modification method, manufacturers can optimize the performance of calcium carbonate in various applications, enhancing the quality of the final products.

Epic Powder

Epic Powder, 20+ years of work experience in the ultrafine powder industry. Actively promote the future development of ultra-fine powder, focusing on crushing,grinding,classifying and modification process of ultra-fine powder. Contact us for a free consultation and customized solutions! Our expert team is dedicated to providing high-quality products and services to maximize the value of your powder processing. Epic Powder—Your Trusted Powder Processing Expert !