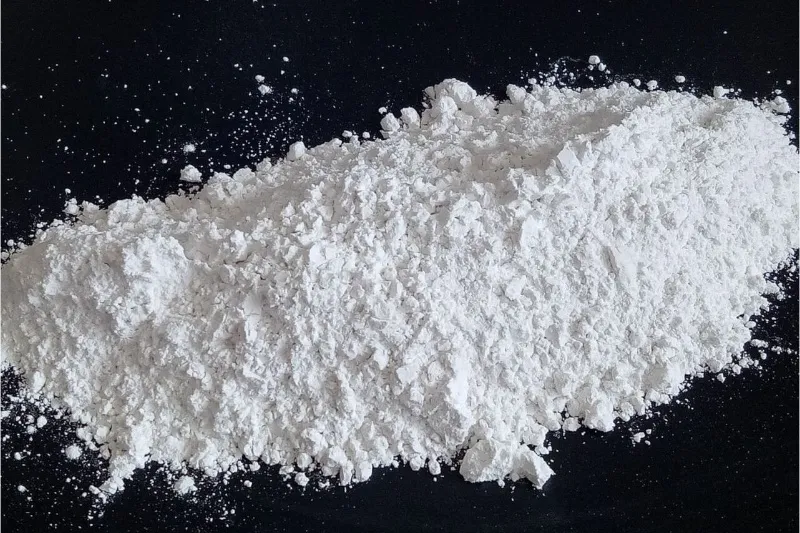

Dolomite is a carbonate mineral, which includes iron dolomite and manganese dolomite. Its crystal structure resembles that of calcite and is commonly found in rhombohedral form. When it comes into contact with cold dilute hydrochloric acid, it slowly produces bubbles. Some dolomites emit an orange-red glow when exposed to cathode rays. Dolomite is the main mineral component of dolostone and dolomitic limestone. Dolomite is widely used in industries like construction materials, ceramics, glass, refractories, chemicals, agriculture, environmental protection, and energy conservation. It is mainly used as an alkaline refractory material and a flux in blast furnace ironmaking, as well as an ingredient in the production of glass and ceramics. Dolomite is selected, crushed, and ground to a particle size ranging from 325 to 1250 mesh to become dolomite powder. Dolomite powder added to natural and synthetic rubber provides similar performance to the addition of light calcium carbonate but at a lower cost.

Dolomite Powder Applications

Glass Industry

Dolomite can reduce glass aging, prevent chemical erosion from air or moisture, improve the plasticity of colored glass, and enhance glass strength. When added to glass production, dolomite powder helps reduce high-temperature viscosity, improving chemical stability and mechanical strength. It has also been shown that dolomite powder in the formulation of low-temperature ceramics and float glass significantly reduces energy consumption.

Environmental Protection

Dolomite has surface adsorption properties, filtration capabilities through pore channels, and ion exchange functions between mineral layers. 200 mesh dolomite is used as an environmental mineral material in the adsorption industry, offering cost-effectiveness and no secondary pollution. It effectively adsorbs heavy metals, phosphorus, boron, and wastewater from dyeing processes.

Refractory Materials

When dolomite is calcined at 1500°C, magnesium oxide turns into periclase, and calcium oxide crystallizes into alpha-calcium oxide, resulting in a dense structure and excellent refractory properties. Dolomite is commonly used as a raw material for refractory materials with a refractory temperature of up to 2300°C. Magnesium-calcium bricks, magnesium-calcium-carbon bricks, magnesium-calcium sand, and spinel-aluminate refractories commonly use 200 mesh dolomite.

Agriculture

Dolomite is used to neutralize acidic soils. Due to the prolonged use of fertilizers like urea, soil tends to become acidic. Adding dolomite directly to urea helps maintain the appropriate pH level of the soil, generally increasing crop yields by 15% to 40%. It also enhances the effectiveness of herbicides, with the best performance observed at a pH of 6.0–6.2. Dolomite can compensate for the loss of magnesium in the soil. Dolomite microparticles ranging from 1.2 to 0.8 μm flow freely and can be used as a fertilizer filler, improving plant access to nutrients and reducing clumping, making it easier to adjust fertilizer ratios.

Animal Feed

Both calcium and magnesium are essential nutrients in animal diets. Adding appropriate amounts of dolomite powder to livestock and poultry feed promotes growth and reduces diseases.

Building Materials

Manufacturing magnesium oxychloride cement is another important use of dolomite. This magnesium-containing cement has excellent compressive strength, bending strength, and corrosion resistance. Magnesium cement produced using dolomite calcined at low temperatures for specific purposes, like flooring, fast-setting pavements, and road crack repairs, has gained wide usage. Furthermore, after dolomite is calcined into caustic dolomite, it can be processed into magnesium hydroxide cement and sulfate magnesium cement. These non-hydraulic materials offer advantages such as a simple production process, fast setting and hardening, high strength, strong bonding ability, good elasticity, wear resistance, and low energy consumption, making them highly valuable for development and use.

Dolomite Powder Production Equipment

The production of dolomite powder typically requires a series of equipment to ensure the required particle size and quality standards are met. The commonly used equipment for dolomite powder production includes:

Crusher: Used for the initial crushing of dolomite, reducing its particle size and facilitating the subsequent grinding process.

Ball Mill: Commonly used to grind dolomite powder to the desired fineness, ranging from 325 mesh to 1250 mesh. Ball mills are suitable for large-scale production.

Vibration Mill: Used for further fine grinding of dolomite to ensure the desired fineness, especially suitable for ultra-fine powder production.

Air Classifier: This equipment is used to classify the ground dolomite powder, ensuring uniformity in particle size distribution. Epic Powder’s air classifier efficiently controls the particle size distribution with high precision.

Surface Modification Equipment: Used for the surface modification of dolomite powder, typically employing chemical modifiers such as stearic acid, titanates, and zirconium-aluminates. Epic Powder offers advanced surface modification equipment that effectively improves the bonding properties of dolomite powder, enhancing its compatibility with materials like rubber and plastics.

Drying Equipment: During the powder production process, necessary drying equipment helps remove moisture and ensures the quality of the powder.

Epic Powder

Epic Powder, 20+ years of work experience in the ultrafine powder industry. Actively promote the future development of ultra-fine powder, focusing on crushing, grinding, classifying and modification process of ultra-fine powder. Contact us for a free consultation and customized solutions! Our expert team is dedicated to providing high-quality products and services to maximize the value of your powder processing. Epic Powder—Your Trusted Powder Processing Expert !