Ball mill is a key equipment for crushing materials after they are broken. Ball mill for powders is one of the high-fine grinding machines widely used in industrial production. It is suitable for grinding various ores and other materials. It is widely used in mineral processing, building materials, and chemical industries.

Why is it Called a “Ball” Mill? What Does “Ball” Mean?

The ball mill crushes materials through grinding media. The transmission mechanism transfers mechanical energy to the grinding media. Various mechanical forces generated between the media crush the materials. The grinding media loaded in the mill are mainly steel balls (steel sections), hence the name “ball mill.”

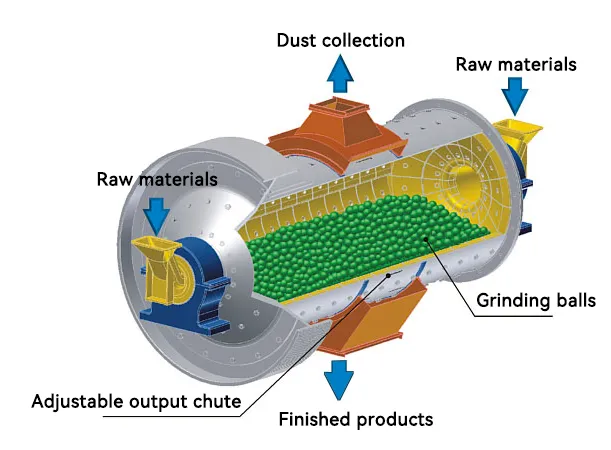

Ball Mill Structure

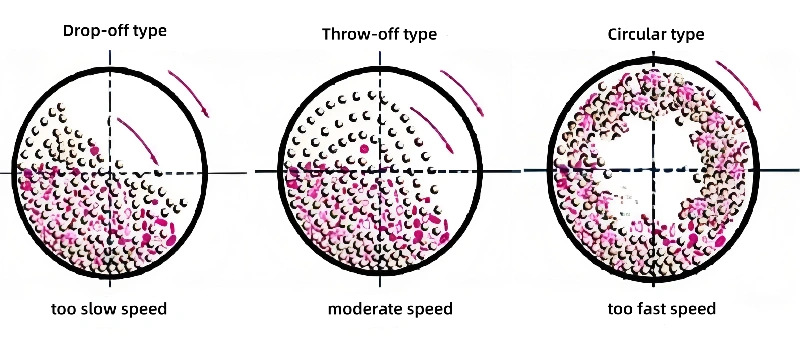

What are the States of Grinding Body?

Drop-off type: The grinding media cannot be raised to the suitable height, only performing grinding with minimal impact force.

Throw-off type: When the grinding media are raised to a certain height, they fall in a parabolic motion, exerting significant grinding and impact force on the material.

Circular type: When the grinding media stay close to the barrel wall without falling, they have no grinding or impact effect on the material.

How to Choose Grinding Media ?

Quantity: The fewer the grinding media, the higher the barrel speed, and the smaller the grinding effect. Conversely, the more the grinding media, the lower the barrel speed, and the greater the grinding effect.

Particle size: The material entering the mill is generally controlled to be less than 15mm.

For large mills, due to their stronger crushing ability, the particle size of the material entering the mill can be increased to 25-30mm.

However, for large vertical raw material mills, the particle size entering the mill can reach up to 100mm. Therefore, the specific particle size should be determined based on different conditions.

Size: For larger or harder materials, the grinding media have a larger average size and fewer quantities. Conversely, for finer or softer materials, the grinding media have a smaller average size and more quantities.

Advantages and Disadvantages of Ball Mill

Advantages:

- Strong adaptability to materials;

- Large crushing ratio;

- Can be operated by dry method or wet method, and drying and grinding can be carried out at the same time;

- Simple structure, high operating rate, reliable operation

Disadvantages:

- Low grinding efficiency and low effective utilization rate of electric energy;

- The equipment is bulky and requires large one-time investment;

- High noise and strong vibration;

- Low speed and requires deceleration equipment.

Conclusion

Generally, the longer the ball milling time, the less noticeable the particle size reduction. Ordinary ball mills for powders can achieve 1-10um particle size. Cyclic stirring ball mills for powders can achieve about 1um. To achieve nanoparticles, ultrafine ball mills for powders are needed, with sizes reaching tens of nanometers.

According to data, some high-energy ball mills for powders can reach about 1 micron. The submicron limit is around 500nm. Using a planetary ball mill for powders for 48 hours can achieve around 70nm, depending on the powder’s properties. The ball-to-material ratio and media affect the ball milling results. Attention to agglomeration is crucial when grinding to nanoscale.

In the fine grinding sector, the demand for particulate materials is growing, offering great opportunities for ball mill for powders development.

Epic Powder

Epic Powder, 20+ years of work experience in the ultrafine powder industry. Actively promote the future development of ultra-fine powder, focusing on crushing,grinding,classifying and modification process of ultra-fine powder. Contact us for a free consultation and customized solutions! Our expert team is dedicated to providing high-quality products and services to maximize the value of your powder processing. Epic Powder—Your Trusted Powder Processing Expert !