Porous calcium carbonate (CaCO3) particles are gaining attention for use in chromatography, biomolecule loading, and pharmaceuticals release. They are also applied in biomimetic minerals and superhydrophobic surface construction.

Preparation Technology of Porous Calcium Carbonate

The template method has become the main approach for preparing porous calcium carbonate.

Surfactants, polymers, and natural plant components are used as templates. With research progress, methods like co-precipitation, emulsion membrane, and solvent/hydrothermal methods have been developed. These methods greatly enrich the preparation techniques.

Among various preparation techniques, the template method is commonly used and well-established. The main principle is to coat the chosen template with calcium carbonate, forming a core-shell structure. The template is then removed through solvent dissolution, high-temperature calcination, or chemical reactions. This process results in hollow structured particles.

The template method is mainly divided into soft and hard template methods, with the soft template method being dominant in porous calcium carbonate preparation. In the template method, small molecular surfactants and organic solvents are used, along with large (high) molecular organic compounds or polymers as templates.

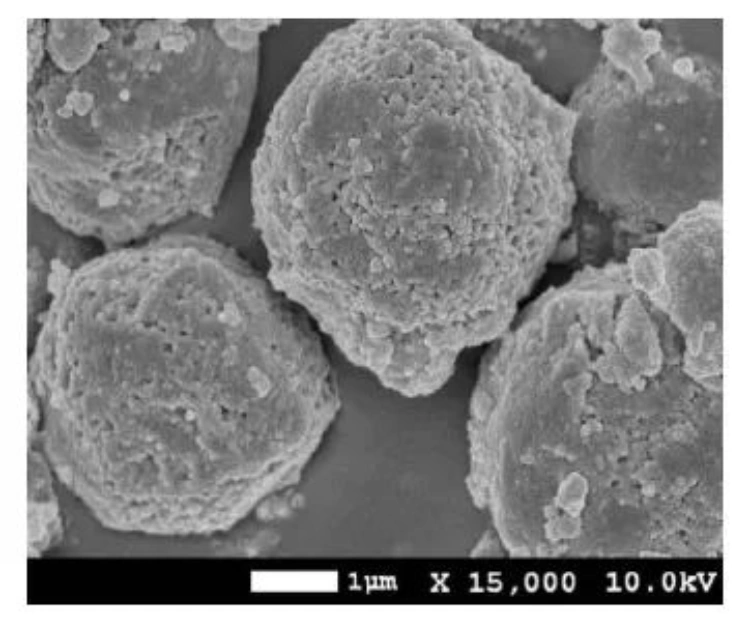

Porous calcium carbonate prepared using the soft template method usually has cubic or spherical shapes. These particles often contain wormhole structures, and their surfaces may have small amounts of template agents or decomposition products.

Calcium Carbonate Pore and Morphology Control Technology

In the preparation of porous CaCO3 particles, the focus is on morphology control and nucleation mechanisms. Morphology control of porous CaCO3 is mainly achieved using surfactants, with the production process also playing a key role. There are various surfactants, including small molecules like anionic L-aspartic acid. Most commonly, polymer-based additives are used, such as anionic polystyrene sulfonate (PSS), nonionic polyvinyl alcohol (PVA), polyacrylamide (PAM), and polyethylene oxide (PEO). Amphiphilic block copolymers (DHBCs) and two-component surfactant systems, like the complex SDS and PEO-PPO-PEO triblock copolymer mixture, are also used.

Application Fields of Porous Calcium Carbonate

The applications of porous calcium carbonate mainly depend on its structure and crystal form.

Therefore, studying its preparation methods and mechanisms has become a hot topic in its development.

Pharmaceutical Carrier

Porous calcium carbonate can serve as a drug carrier material, offering high drug loading capacity and good sustained release performance. Especially when wrapped with a responsive shell material, it can prevent sudden pesticide release and enhance the drug delivery system’s responsive functions. This results in a system with multi-responsive controlled release properties.

Battery Materials

Researchers have first used nanoscale calcium carbonate as a solid electrolyte additive in lithium metal batteries. It binds by-products like HF in the electrolyte, suppressing the acidity and forming a denser, more robust SEI layer. The released Ca2+ ions in EC/DEC can adsorb onto the metal surface, providing an electrostatic shielding effect.

Plastic Materials

Porous calcium carbonate has versatile applications in plastics. On one hand, it serves as a filler to enhance mechanical and optical properties. On the other hand, it acts as a nucleating agent to improve processability.

Adsorption Material

The high specific surface area and porosity of porous calcium carbonate give it excellent adsorption properties. A certain institution invented a method for defluorinating lithium mica flotation wastewater, using a defluorinating agent that includes a precipitant and an adsorption disrupting agent. The adsorption disrupting agent is porous calcium carbonate loaded with NaOH and AlCl3. By adding the adsorption disrupting agent to the defluorinating agent, it addresses the challenge of removing fluoride from fluorosilicic acid complexes.

Adhesive Material

A company invented a high-adhesion, solvent-resistant adhesive and its preparation method, along with a polyimide composite film and screen printing stencil. The adhesive is modified with phenylsilane coupling agents and loaded with 18-30 parts of a curing agent. The high curing agent load provides the product with high adhesion and solvent resistance, making it especially suitable for bonding polyimide films and metal meshes for screen printing stencils.

Paper-based Facing Materials

A company invented a paper-based decorative material with UV resistance. In this material, porous calcium carbonate fillers are loaded with titanium dioxide, successfully creating a paper-based surface with excellent UV protection.

Biosensors

Biosensors are rapid, trace-level analysis methods at the molecular level. They have broad application prospects in clinical diagnosis, industrial control, food and drug analysis, environmental protection, and biotechnology research.

Asphalt Pavement Material Admixture

A company invented an asphalt pavement additive, self-healing asphalt pavement, and its preparation method. The additive is a composite material made from silver nanowire-modified microcapsules, asphalt rejuvenator, and porous calcium carbonate. The composite material slowly and effectively releases the asphalt rejuvenator as the asphalt pavement forms, compensating for the loss of aromatic components in the asphalt. This delays the aging and cracking process of the asphalt. The synergistic effect of both components enhances the durability and self-healing ability of the asphalt pavement, making it highly practical.

Bioceramics

Due to its excellent osteoconductivity, biocompatibility, and degradability, calcium carbonate is widely used in biology and medicine. In the early 1990s, porous calcium carbonate was already used for the in vitro culture of human bone marrow cells, fibroblasts, gingival fibroblasts, and fetal rat osteoblasts. Compared to other materials, porous calcium carbonate not only has good porosity, pore size, and pore connectivity but also shows better biocompatibility. It helps guide bone regeneration and repair. Clinically, in orthopedics and oral maxillofacial surgery, porous calcium carbonate has been used for bone defect repair, achieving good results.

Conclusion

Currently, research on porous calcium carbonate is more focused on its high-end applications. Due to its porous structure, high specific surface area, and porosity, it is used as a water treatment agent to adsorb dissolved substances and colloidal materials in water. However, research on porous calcium carbonate’s adsorption of gas pollutants, fine particulate matter, and heavy metals still requires further breakthroughs.

Epic Powder

Epic Powder, 20+ years of work experience in the ultrafine powder industry. Actively promote the future development of ultra-fine powder, focusing on crushing,grinding,classifying and modification process of ultra-fine powder. Contact us for a free consultation and customized solutions! Our expert team is dedicated to providing high-quality products and services to maximize the value of your powder processing. Epic Powder—Your Trusted Powder Processing Expert !