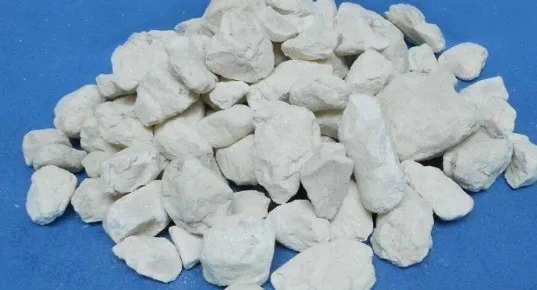

Limestone, also known as “Qing Stone” or “Gray Rock,” is a mineral aggregate primarily composed of calcite. It often contains dolomite, magnesite, and other carbonate minerals. The chemical composition of pure limestone is close to the theoretical composition of CaCO3, with CaO accounting for 56.04% and CO2 for 43.97%. Limestone is a common non-metallic mineral and a valuable resource with wide applications. The applications of limestone covers many fields such as construction, metallurgy, environmental protection, and chemical industry. For example, it is a key material for manufacturing cement, steelmaking flux, flue gas desulfurization, and the production of calcium carbonate. It is an indispensable basic raw material for industrial development. It is specifically reflected in the following aspects:

Direct Applications of Limestone

Cement Manufacturing

Limestone is the main raw material for cement, making up 70%-90% of the raw material mix. It helps increase cement production, reduce consumption, save resources and energy, and reduce pollution.

Glass Production

Limestone, quartz sand, and soda ash are used to make glass after high-temperature melting.

Carbide Production

Limestone is a key raw material for producing calcium carbide, which is used to produce acetylene gas, an essential raw material for synthetic fibers, rubber, and plastics.

Soda Ash Production

Soda ash is produced from limestone, salt, and ammonia using the Solvay process. It is a key chemical raw material used in glass, ceramics, and cleaning.

Building Materials

Limestone can be processed into stones and crushed stones for building. It is used as a flooring material and aggregate in concrete and asphalt.

Indirect Applications of Limestone—Quicklime

Limestone can be made into quicklime after calcination. Quicklime CaO plus water becomes slaked lime Ca(OH)2, which can be processed into lime calcium powder. Slaked lime can be prepared into lime slurry, lime paste, etc. In addition, quicklime is also the raw material for processing calcium carbide and caustic soda.

Agriculture, forestry and animal husbandry

First, quicklime can be made into pesticides such as Bordeaux mixture and lime-sulfur mixture. Second, slaked lime can change the acidity and alkalinity of the soil, improve the internal composition of the soil, and supplement the calcium in the soil. Then, lime slurry can be used to paint tree trunks and protect trees. In addition, limestone can be used in the production of feed as a calcium supplement to increase the calcium content of feed. It is used as a filter aid in sugar production to clarify the juice of beets and sugarcane.

Water Softening

Hydrated lime can temporarily remove the hardness of water, and is therefore used as a water softener in industry.

Drying and Disinfection

When quicklime is added with water, it can generate heat and calcium hydroxide, which is highly alkaline and has strong hygroscopicity. Slaked lime can kill a variety of pathogens and can be used to disinfect walls, floors, manure pits, sewage ditches, etc.

Bleaching Agent

Slaked lime reacts with chlorine to produce bleaching agents.

Steel Production

Limestone is used as a flux in ironmaking to remove high-melting-point silicon dioxide (gangue SiO2) from iron ore. Quicklime is used as a slag-making material in steelmaking to remove harmful impurities such as sulfur and phosphorus. In addition, lime is added to the alumina production process for catalysis.

Construction Industry

Slaked lime is mixed into lime slurry, lime paste, lime mortar, etc., which are used as coating materials and brick and tile adhesives. Lime powder can be produced into OK powder, latex paint special powder, porcelain gloss powder and other series of products.

Calcium Salt Production

Limestone is chemically processed to produce calcium salts like calcium chloride, calcium nitrate, and calcium sulfite.

Environmental Protection

On the one hand, the limestone-gypsum wet flue gas desulfurization process is currently the most widely used desulfurization technology. Limestone has good chemical activity and low price as a raw material for desulfurization agent preparation. SO2 reacts with limestone slurry to generate calcium sulfite, which is pumped into the dehydrator through the gypsum discharge pump to remove gypsum and the clean flue gas is discharged. On the other hand, chemical precipitation can be used to treat industrial wastewater to remove calcium ions and heavy metal ions in the water, and the lime method is one of them.

Indirect Applications of Limestone—Calcium Carbonate

The main component of limestone is calcium carbonate (CaCO3), which can be used to produce heavy calcium carbonate through mechanical crushing and ultrafine grinding. Light calcium carbonate and nano calcium carbonate can be produced through calcination, digestion, carbonation, separation, drying and classification. Calcium carbonate, as an important inorganic filler, is widely used in coatings, inks, plastics, rubber, papermaking, medicine, daily chemicals and other industries.

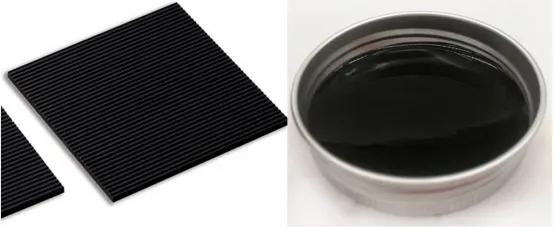

Rubber Industry

Adding calcium carbonate can improve the dispersibility, vulcanization elongation, tear resistance, compression deformation, flex resistance and crack resistance of rubber products.

Plastic Industry

Calcium carbonate increases plastic volume, lowers product cost, and improves dimensional stability, hardness, rigidity, and heat resistance.

Paper Industry

Calcium carbonate increases paper brightness, smoothness, and softness while enhancing paper’s pliability and density.

Ink Industry

After surface treatment, calcium carbonate has a higher yield value when applied to ink and can form a colloid structure with a certain strength. It can control the ink to penetrate into the paper fiber, so that more resin remains on the paper surface, and the ink film formed has high gloss and good transparency.

Coatings Industry

Filling paint with nano calcium carbonate can improve the flexibility, hardness, leveling and optical properties of the paint. Adding it to latex can form a shielding effect on the paint. It can achieve the effect of anti-ultraviolet and anti-heat aging, and increase the heat insulation of the paint. At the same time, nano calcium carbonate has a steric hindrance effect. In the paint making process, it can suspend the denser lead powder in the formula to prevent sedimentation. After the paint is made, the whiteness of the paint film increases, the gloss is good, and the hiding power is not reduced.

Other Applications

Calcium carbonate is used in health products, feed, daily chemicals (cosmetics, soaps, toothpaste), and ceramics.

Conclusion

In conclusion, limestone has wide applications. As a new, eco-friendly raw material, the demand for limestone is increasing. With advancements in science and technology, especially in nanotechnology, limestone’s application range will continue to expand.

Epic Powder

Epic Powder, 20+ years of work experience in the ultrafine powder industry. Actively promote the future development of ultra-fine powder, focusing on crushing,grinding,classifying and modification process of ultra-fine powder. Contact us for a free consultation and customized solutions! Our expert team is dedicated to providing high-quality products and services to maximize the value of your powder processing. Epic Powder—Your Trusted Powder Processing Expert !