Toz yüzey modifikasyonu fiziksel olarak toz yüzeyinin işlenmesini içerir, kimyasal, veya mekanik yöntemler. Amaç, fiziksel ve kimyasal özelliklerini değiştirmek veya yeni işlevler kazandırmaktır. Bu, modern malzemelerin, süreçlerin ve teknolojilerin ihtiyaçlarını karşılar. Yüzey modifikasyonunun ve toz özelliklerinin rolünü anlamak, malzeme performansını iyileştirmeye yardımcı olur. Değiştirici miktarını kontrol etmek, doğru ekipmanı ve süreci seçmek, toz uygulamaHatta tozlara yeni işlevler veya performans yetenekleri bile kazandırabilir.

Modifikasyonun rolü

Rolü toz yüzey modifikasyonu uygulamaya göre değişir. Ana hedef toz performansını artırmak veya yeni işlevler kazandırmaktır. Bu, yeni malzemelerin, teknolojilerin ve ürün geliştirmenin ihtiyaçlarını karşılar. Toz modifikasyonunun beş ana işlevi vardır:

- İnorganik dolgu maddelerini basit katkı maddelerinden fonksiyonel dolgu maddelerine dönüştürün.

- Polimerler ve kompozit malzemeler için yeni teknolojiler sağlamak.

- Parçacık dağılımını iyileştirin ve kümeleşmeyi önleyin.

- Toz malzemelerin stabilitesini ve ürün performansını arttırır.

- Çevresel sürdürülebilirliği ve ekonomik üretimi geliştirerek katma değeri artırmak.

Toz hammadde özellikleri

Toz malzemelerin özellikleri esas olarak asitlik, alkalinite, yüzey yapısı, fonksiyonel gruplar, adsorpsiyon ve kimyasal reaktiviteyi içerir. Yüzey değiştiriciler mümkün olduğunda toz yüzeyine kimyasal olarak reaksiyona girmeli veya adsorbe olmalıdır. Fiziksel adsorpsiyon, daha sonraki uygulamalarda güçlü karıştırma veya ekstrüzyon altında desorbe olabilir. Örneğin, kuvars, feldispat, mika ve kaolin gibi silikat mineralleri silan bağlama maddeleriyle bağ yapabilir. Bu, güçlü bir kimyasal adsorpsiyon oluşturur. Ancak, silan bağlama maddeleri genellikle karbonat bazlı alkali minerallerle reaksiyona girmez veya adsorbe olmaz. Titanatlar ve alüminatlar, belirli koşullar altında karbonat bazlı alkali minerallere adsorbe olabilir. Bu nedenle, silan bağlama maddeleri hafif ve ağır gibi karbonat bazlı alkali mineralleri modifiye etmek için uygun değildir kalsiyum karbonat.

Değiştirici dozaj

Parçacıklar üzerinde tek tabakalı adsorpsiyon için yüzey değiştiricinin optimum miktarı tozun özgül yüzey alanına ve değiştiricinin moleküler kesit alanına bağlıdır. Ancak bu miktar, yüzey değiştiricinin 100% kapsamına karşılık gelmeyebilir. İnorganik yüzey için kaplama Modifikasyon, farklı kaplama oranları ve katman kalınlıkları, renk ve parlaklık gibi çeşitli özellikler gösterebilir. Bu nedenle, gerçek optimum miktar modifikasyon ve performans testleri yoluyla belirlenmelidir. Bunun nedeni, modifikatör miktarının hem yüzey modifikasyonu sırasında kaplamanın dağılımı hem de düzgünlüğü ile ilişkili olmasıdır. Ayrıca, uygulama sisteminin tozun yüzey özellikleri ve teknik özellikleri için özel gereksinimlerine de bağlıdır.

Değişiklik süreci

Yüzey değiştirici miktarı ve formülasyonu belirlendikten sonra, yüzey değiştirme işlemi etkiyi etkileyen temel faktörlerden biridir. İşlem, yüzey değiştiricinin uygulama gereksinimlerini veya koşullarını karşılamalıdır. Değiştiricinin iyi dağılmasını sağlamalı ve toz yüzeyinde düzgün ve güçlü bir kaplama elde etmelidir. Aynı zamanda, işlem basit olmalı, kontrol edilebilir parametrelere, istikrarlı ürün kalitesine, düşük enerji tüketimine ve minimum kirliliğe sahip olmalıdır.

Modifikasyon ekipmanları

Toz Boya için Turbo Değirmen

Güçlü girdap akış alanı, anında öğütme ve kaplama

Konik rotor ve stator benimsenmiştir ve rotor ile stator arasındaki boşluk ayarlanabilir; Güçlü girdap akış alanı, rotorun doğrusal hızı 120 m/s'ye ulaşabilir; bu, özellikle topaklanmış malzemelerin dağılması, azaltılması ve ezilmesi için uygundur. Taşlama ve kaplama işlemini tamamlamak için malzeme rotor ile stator arasında yüksek hızda çarpılır, kesilir ve ovalanır.

Bu sürekli toz yüzey kaplama sistemi, Çin ekipmanlarıyla Alman uzmanlığı temelinde tasarlanmıştır ve aşağıdakiler gibi çeşitli tozların kaplanması için kullanılabilir: kalsiyum karbonat (GCC, PCC), kaolin, talk, mika, grafit, baryum sülfat, beyaz karbon siyahı, magnezyum hidrat, çinko oksit, alüminyum oksit ve alüminat bağlayıcı madde, titanat bağlayıcı madde, silan bağlayıcı madde ve stearik asit gibi çeşitli katı/sıvı kaplama maddeleri için uygundur. Kaplama makinesi üç ünite karıştırma odasından oluşur. Yüksek hızlı dönüş, bu özel şekilli odaların içinde büyük girdap akışı yaratır. Toz ve kaplama maddesi, yüksek hızlı gaz-katı girdap akışlarında karıştırılır.

Hem yüzey kaplama hem de partikül dağıtma işlevlerine sahip kaplama makinesi, farklı incelikteki çeşitli tozlar için uygundur ve küçük görünen özgül ağırlığa ve yüksek hacim/ağırlık oranına sahip malzemeler için benzersiz bir kaplama etkisine sahiptir. Otomatik sıcaklık kontrol sistemi, kaplama maddesinin sıvıya erimesi ve kaplanmamış tozla karışması için kararlı yüksek sıcaklık sağlar. Toz ve kaplama maddesinin ısıtılması ve soğutulması, bağımsız bir soğutma sistemine ihtiyaç duymayan tek bir makinede tamamlanır. Kaplama maddesinin yüksek kullanım oranı, yüksek toz kaplama oranı, yüksek aktivasyon derecesi, düşük enerji tüketimi ve son kaplanmış üründe çok az aglomera. Tüm sistem negatif basınç altında, toz emisyonu olmadan ve düşük iş gücü yoğunluğunda çalıştırılır.

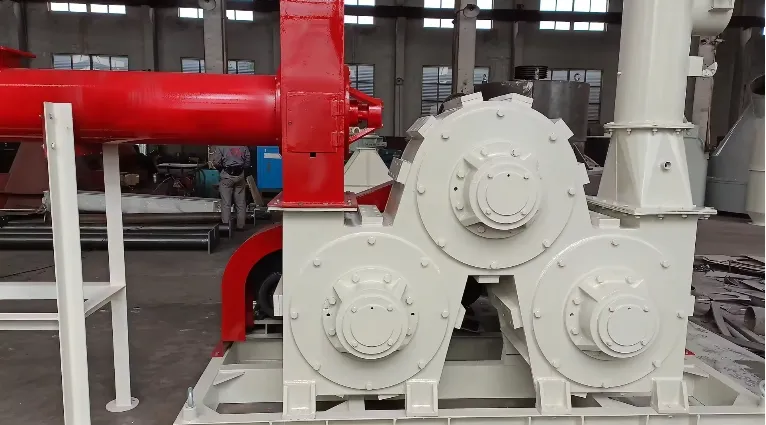

Toz Boya için Üç Silindirli Değirmen

Kaplama toz yüzeyini siklon girdabını değiştirerek farklı malzemelere ve uygulama endüstrilerine göre üretim kapasitesi ve parçacık boyutu aralık farklı olacaktır. Lütfen ekipmanı sizin için özelleştirmek üzere mühendislerimizle iletişime geçin. Uzmanlarımız makine ve proses ihtiyaçlarınızı görüşmek üzere 6 saat içinde sizinle iletişime geçecektir.

Bu sürekli toz yüzey kaplama sistemi, Çin ekipmanlarıyla Alman uzmanlığı temelinde tasarlanmıştır ve aşağıdakiler gibi çeşitli tozların kaplanması için kullanılabilir: kalsiyum karbonat (GCC, PCC), kaolin, talk, mika, grafit, baryum sülfat, beyaz karbon siyahı, magnezyum hidrat, çinko oksit, alüminyum oksit ve alüminat bağlayıcı madde, titanat bağlayıcı madde, silan bağlayıcı madde ve stearik asit gibi çeşitli katı/sıvı kaplama maddeleri için uygundur. Kaplama makinesi üç ünite karıştırma odasından oluşur. Yüksek hızlı dönüş, bu özel şekilli odaların içinde büyük girdap akışı yaratır. Toz ve kaplama maddesi, yüksek hızlı gaz-katı girdap akışlarında karıştırılır.

Hem yüzey kaplama hem de partikül dağıtma işlevlerine sahip kaplama makinesi, farklı incelikteki çeşitli tozlar için uygundur ve küçük görünen özgül ağırlığa ve yüksek hacim/ağırlık oranına sahip malzemeler için benzersiz bir kaplama etkisine sahiptir. Otomatik sıcaklık kontrol sistemi, kaplama maddesinin sıvıya erimesi ve kaplanmamış tozla karışması için kararlı yüksek sıcaklık sağlar. Toz ve kaplama maddesinin ısıtılması ve soğutulması, bağımsız bir soğutma sistemine ihtiyaç duymayan tek bir makinede tamamlanır. Kaplama maddesinin yüksek kullanım oranı, yüksek toz kaplama oranı, yüksek aktivasyon derecesi, düşük enerji tüketimi ve son kaplanmış üründe çok az aglomera. Tüm sistem negatif basınç altında, toz emisyonu olmadan ve düşük iş gücü yoğunluğunda çalıştırılır.

Toz Kaplama için Pim Değirmeni

Pin tipi kırma diski, elek yapısı yok, hızlı hız, büyük kapasite ve düşük ısı üretimi. Tek güç veya çift güç seçilebilir, hat hızı 240 m/s'ye kadar ulaşabilir, güçlü darbe kuvveti ve kesme kuvveti ve ürün parçacık boyutu iyidir. Dağıtma ve deaglomerasyon için uygundur. Ultra ince toz ve sıvı ve parçacık yüzeyi için sürekli yüksek hızlı karıştırma için uygundur kaplama modifikasyonu. Bir ile donatılabilir hava sınıflandırıcı Ürün inceliğini kontrol etmek için. Kompakt yapıdaki değirmenin sökülmesi ve temizlenmesi son derece kolaydır.

Çözüm

Sonuç olarak, toz yüzey modifikasyon teknolojisi, çeşitli endüstriyel uygulamalar için tozların özelliklerini ve performansını artırmada önemli bir rol oynar. Doğru modifikatörleri seçerek ve modifikasyon sürecini optimize ederek, modern malzemelerin ve teknolojilerin taleplerini karşılayan gelişmiş dağılım, kararlılık ve işlevsellik elde etmek mümkündür. Yenilik devam ettikçe, yüzey modifikasyonu yeni malzemelerin geliştirilmesinde ve ürün performansının artırılmasında önemli bir faktör olmaya devam edecektir.

Epik toz

Epic Powder, ultra ince toz endüstrisinde 20+ yıllık iş deneyimi. Ultra ince tozun gelecekteki gelişimini aktif olarak teşvik edin, ultra ince tozun ezilmesi, öğütülmesi, sınıflandırılması ve modifikasyon sürecine odaklanın. Ücretsiz danışmanlık ve özelleştirilmiş çözümler için bizimle iletişime geçin! Uzman ekibimiz, toz işleme değerinizin en üst düzeye çıkarılması için yüksek kaliteli ürünler ve hizmetler sunmaya kendini adamıştır. Epic Powder—Güvenilir Toz İşleme Uzmanınız!