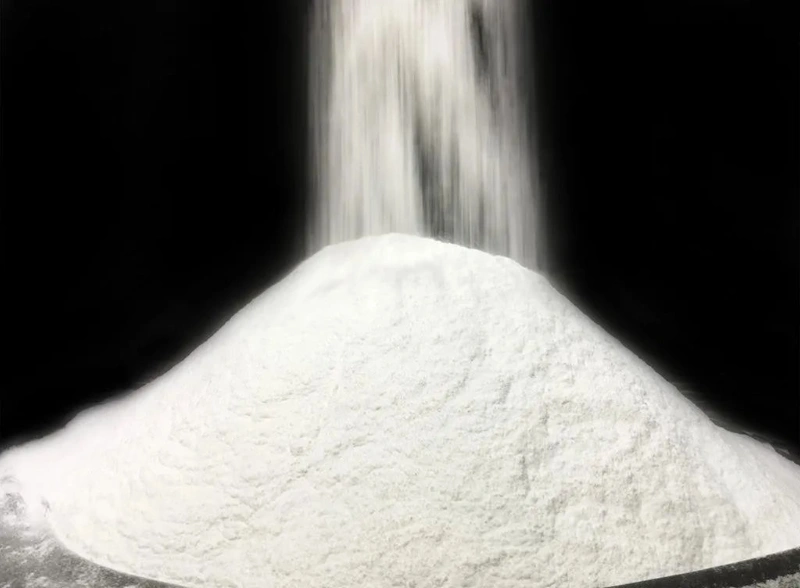

Have you ever wondered why smartphone screens are becoming more scratch-resistant, or why cosmetics adhere more smoothly to the skin? The answer often lies in ultrafine powder.

As industrial technology continues to advance, ultrafine powder has not only transformed our daily lives but has also become a key foundational material in strategic industries such as new energy, electronics, and pharmaceuticals.

New Energy: The Booming Demand for Battery Materials

Amid the surge in electric vehicles and energy storage systems, the lithium battery industry is entering a golden era.

By 2025, the market size for grinding equipment for lithium battery materials is expected to reach around 18 billion RMB.

As essential raw materials for cathodes (such as lithium iron phosphate), anodes (such as graphite and silicon–carbon composites), and separator coatings (such as alumina and aluminum hydroxide), ultrafine powders are in growing demand.

Advantages of ultrafine particles:

The finer the particles, the more complete the electrochemical reactions—significantly improving the battery’s energy density and cycle life.

Equipment demand:

High-energy ball mills, jet mills, and air classifiers have become standard equipment in the processing of battery materials.

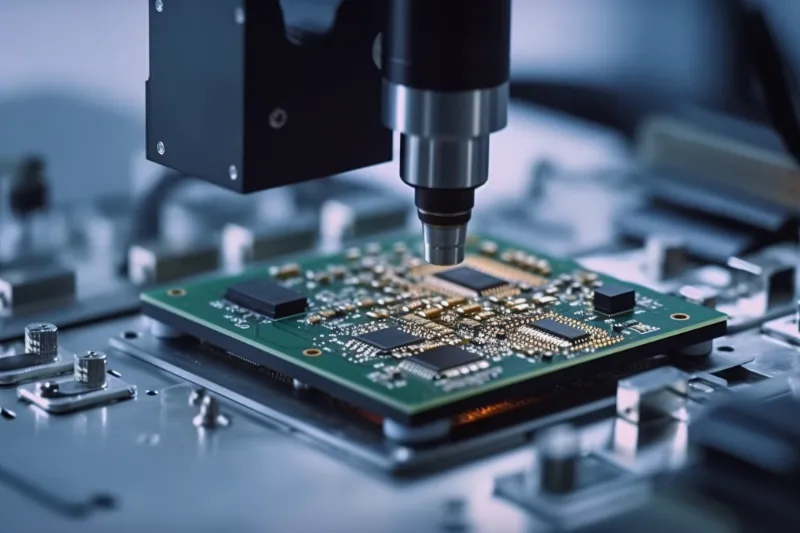

Electronics Industry: Semiconductors and Polishing Materials

Ultrafine powder plays a crucial role in chemical mechanical polishing (CMP) for semiconductor wafers.

Polishing materials represented by ceria and silica ultrafine powders determine the precision and yield of chip manufacturing.

Huge potential for domestic substitution:

Currently, some high-end powders and grinding equipment rely on imports. With the acceleration of localization, domestically produced ultrafine powders and equipment are expected to gain a broad market foothold.

Application fields: Semiconductor polishing, LED, optical glass processing, and more.

Pharmaceuticals and Chemicals: Precision and Functionality

Ultrafine powder is also ubiquitous in food, pharmaceuticals, and cosmetics:

- Pharmaceuticals: Ultrafine processing improves solubility and absorption, enhancing efficacy.

- Cosmetics: Ultrafine talc and titanium dioxide improve adhesion and long-lasting effects.

- Chemicals: Catalysts, flame retardants, and fillers all rely on ultrafine powders to provide larger surface areas and higher activity.

Technological Upgrades: From Micron to Nano and Beyond

Ultrafine powder technology is steadily advancing toward the nanometer scale.

Trend: D50 values have reached the 1 μm level or even finer, and some materials can already be mass-produced at the nanoscale.

Intelligent control: Modern grinding systems integrate smart monitoring and automatic adjustment, allowing real-time optimization of grinding force and classification precision—improving energy efficiency and reducing power consumption.

The Industrial “Magic Formula” of Ultrafine Powder

- A human hair: ~75 μm

- Ordinary flour (100 mesh): ~150 μm

- Ultrafine powder: <10 μm

This simple comparison shows the power of being fine.

Industry term glossary:

- D50: The average particle size—half the particles are smaller, half are larger.

- D97: The “large-particle alarm”—97% of particles are smaller than this size.

- Specific surface area: The “secret weapon” of powder activity—the larger it is, the faster the reactions (but the poorer the flowability).

Grinding Equipment: The Hidden Heroes Behind Ultrafine Powder

Achieving micron- or nanometer-scale powders requires high-performance grinding systems. Common equipment includes:

- Ball Mill: A mature design for long-duration grinding of hard materials; can form a closed circuit with a classifier.

- Jet Mill: Uses high-speed airflow for particle collision grinding—ideal for high-purity, low-contamination powders in pharmaceuticals and electronics.

- Air Classifier Mill (ACM): Combines grinding and classification in one system, offering low energy consumption and controllable particle distribution—suitable for coatings, chemicals, and mineral powders.

- Roller Mill: Uses rollers and rings to compress and grind materials, providing stable fine powder output—widely used in non-metallic mineral ultrafine grinding.

- Air Classifier: Determines particle size distribution, ensuring the powder is fine yet uniform.

By combining these systems, manufacturers can precisely control D50, D97, and other particle size metrics—producing ultrafine powders that meet the exact demands of each industry.

Conclusion: Ultrafine Powder — The Invisible Engine of Modern Industry

Ultrafine powder is not just “finer powder”—it is the invisible engine driving modern industry.

From new energy batteries to semiconductor manufacturing, from pharmaceuticals to green materials, ultrafine powder is rewriting the rules of countless industries. Epic Powder with over 20 years of expertise in ultrafine grinding and classification technology. Epic Powder provides complete solutions for crushing, grinding, classification, and surface modification—covering materials such as calcium carbonate, silicon powder, lithium battery materials, and more.

With advanced equipment like jet mills, ball mill classification systems, and air classifier mills, Epic Powder empowers global partners to achieve stable, efficient, and intelligent powder processing—defining new standards and driving the future of ultrafine materials.