Polypropylene (PP) is a widely used thermoplastic polymer, known for its easy processing and excellent properties. This makes it essential in industries such as packaging, home appliances, and automotive parts. Despite its widespread use, PP has certain limitations. These include high thermal shrinkage, poor performance in low temperatures, and inadequate impact resistance. These shortcomings have driven the development of strategies to enhance PP’s properties. One effective method is the incorporation of various mineral powders for polypropylene modification, enhancing its overall performance. By adding inorganic mineral powders, such as calcium carbonate, talc, and mica, the thermal stability of PP can be improved. This also enhances its impact strength and overall performance. As a result, PP’s applicability is broadened across diverse industries and challenging environments.

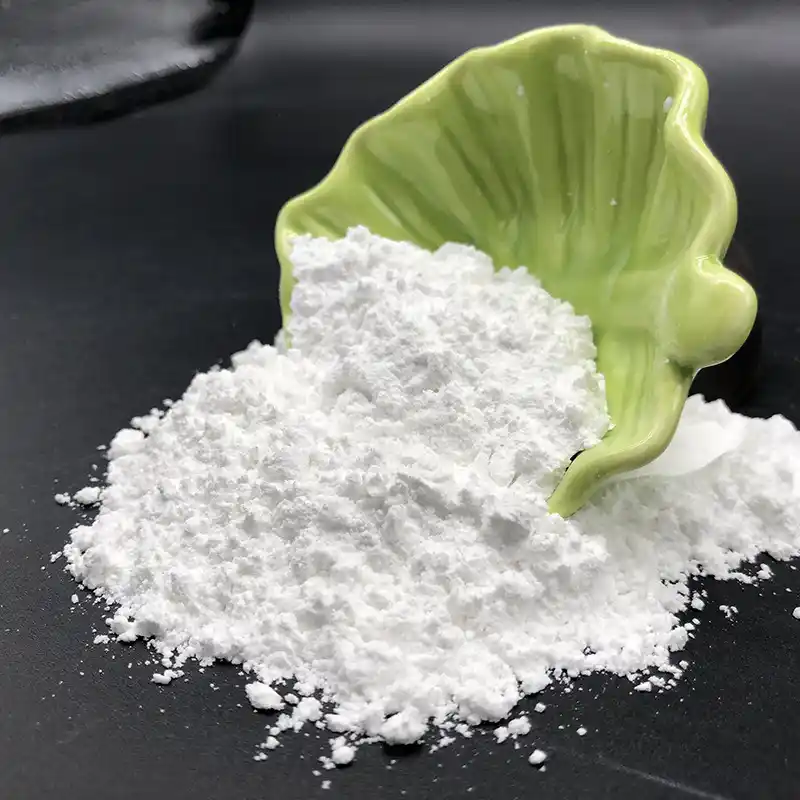

Calcium Carbonate

Calcium carbonate, with its abundant resources, variety, non-toxicity, and ease of processing, is widely used in resin fillers. Its application is particularly significant in polypropylene (PP) fillers. Calcium carbonate is mainly divided into three types: nano, heavy, and light calcium carbonate. These different types of calcium carbonate powders exhibit unique performance impacts in polypropylene modified fillers, based on their specific physical and chemical properties.

Talc

Talc, a natural mineral rich in magnesium silicate, has a unique layered structure, good insulation, and stability. It is widely used in polypropylene (PP) applications. Talc significantly reduces the shrinkage rate of PP materials. It also enhances the tensile modulus to some extent, improving mechanical properties and stability.

Mica

Mica, with its unique physical and chemical properties, plays an important role in insulation materials, plastics, rubber, paper, and paints. Mica has a special large aspect ratio structure, enhancing plastic products. It improves the physical properties of mechanical parts, vehicle components, plastic wood products, appliance housings, and packaging products. Mica also enhances the properties of films, fibers, and ropes.

Silicon Dioxide

Silica powder, a widely used inorganic material, is favored for its high purity, uniform shape, and various preparation methods. In particular, nano-silica has a unique three-dimensional network structure and large specific surface area. It can significantly enhance the overall performance of composite materials. This is especially true when applied to polymer products.

Kaolin

Kaolin is primarily composed of kaolinite clay minerals. It is a powder formed during the weathering of feldspar, pyroxenes, and other aluminosilicate minerals. This powder typically has a dull appearance. When pure, it has a white and fine texture. It exhibits plasticity, adhesiveness, and volumetric expansion. Kaolin can improve the tensile strength and modulus of thermoplastic materials, enhancing the rigidity and strength of plastic products. When added to polypropylene, it also serves as a nucleating agent. After calcination, kaolin significantly improves the electrical insulation strength of plastics and can be used in wires, cables, and high-voltage insulation products. Kaolin’s ability to block infrared radiation is notable, and it has been applied in military equipment. In films, it can improve thermal insulation properties.

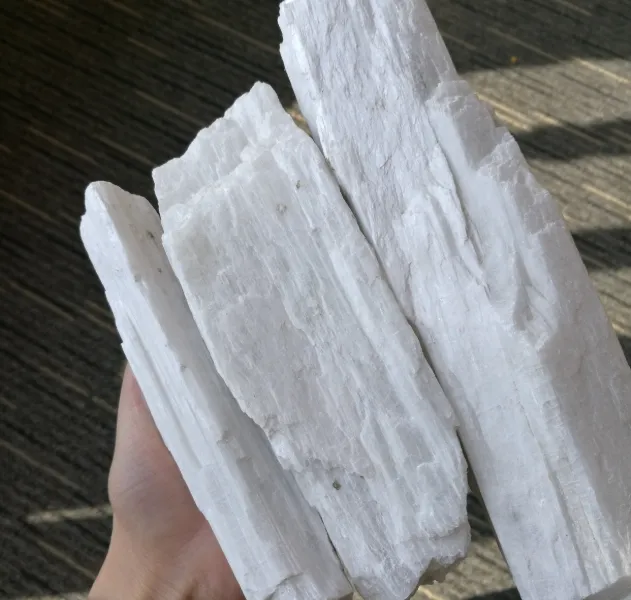

Wollastonite

Wollastonite can be widely used in resins such as PET, PA, PE, PP, and ABS. Many of its properties are similar to those of inorganic powders like talc and mica. As a new inorganic modifier for plastics, the processing technique should focus on maintaining the large aspect ratio of its fibrous structure. Surface activation modification with silane coupling agents is used to improve or ensure compatibility between different material interfaces. Wollastonite can increase the heat distortion temperature of resins. It improves the drawback of strength and modulus reduction in moisture-sensitive resins. This occurs when the resins are exposed to humid environments. The physical properties also show significant improvements, depending on the resin used.

Barium Sulfate

Barium sulfate (BaSO4) can be classified into two types: natural barium sulfate, also known as barite powder, and synthetic barium sulfate. Synthetic barium sulfate has a specific surface area ranging from 22,000 to 140,000 cm²/g. As a plastic filler, it smoothens the surface of products and imparts good gloss. Barium sulfate also offers excellent properties such as chemical stability, scratch resistance, heat resistance, refractive index, and ease of dispersion. It provides superior sound insulation, thermal insulation, and high gloss compared to many other inorganic powders. It is widely used in applications like appliance housings, masterbatches, films, pipes, and profiles. However, the specific gravity of barium sulfate is an important factor influencing its application performance.

Conclusion

There is a wide variety of inorganic powders, and the application of these powders in PP modification technologies is relatively mature. Especially considering the diverse downstream applications, the performance requirements for PP inevitably vary. In this context, the rich range of mineral powders for polypropylene modification offers more options, enabling targeted filling modification to meet specific performance needs. By selecting appropriate mineral powders, PP’s mechanical properties can be tailored for various industries. PP’s thermal and chemical properties can also be adjusted to meet specific needs. This improves the material’s overall versatility and performance in different applications.

Epic powder

Epic Powder, 20+ years of work experience in the ultrafine powder industry. Actively promote the future development of ultra-fine powder, focusing on crushing,grinding,classifying and modification process of ultra-fine powder. Contact us for a free consultation and customized solutions! Our expert team is dedicated to providing high-quality products and services to maximize the value of your powder processing. Epic Powder—Your Trusted Powder Processing Expert !