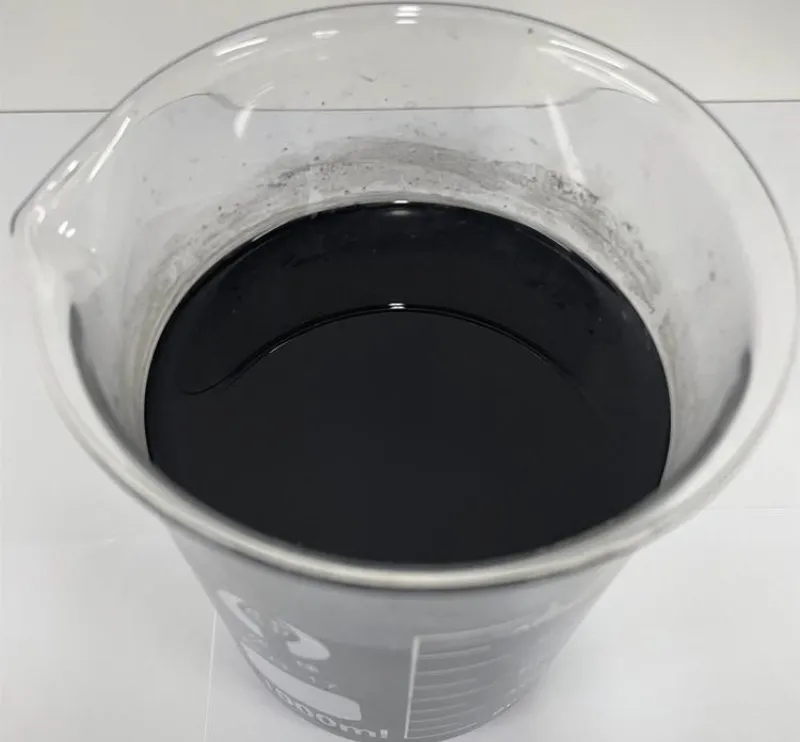

Slurry is the core raw material in electrode manufacturing. Its quality directly determines the energy density, cycle life, and safety performance of batteries. Today, we break open the “technical black box” and explain in the simplest terms the five key indicators of lithium battery slurry—helping you instantly judge battery quality.

Solid Content: The “Invisible Switch” of Battery Capacity

Definition: The percentage of solid active materials (such as lithium cobalt oxide for cathodes and graphite for anodes) in the total lithium battery slurry mass.

Industry Insights:

- Every 5% increase in solid content can boost energy density by 3%–8%, directly improving driving range;

- Too high → poor dispersion; too low → higher manufacturing costs;

- Leading companies have pushed solid content above 70%, while smaller firms hover around 60%.

User Value: Higher solid content = lighter battery packs + longer range, relieving EV owners of mileage anxiety!

Viscosity: The “Balancing Act” of Flow and Coating

Definition: The slurry’s resistance to flow, measured in Pa·s (Pascal-seconds).

Technical Challenges:

- Too low: slurry runs during coating, causing uneven electrode thickness;

- Too high: difficult to pump, increasing equipment wear;

- Optimal viscosity must be dynamically adjusted according to coating speed and drying temperature.

Case Example: A rising EV maker once saw yield rates plunge by 40% due to slurry viscosity issues!

Particle Size Distribution: The “Energy Code” of the Micro World

Definition: The size and uniformity of active material particles, measured by D50 (median size) and Span (distribution width).

Key Insights:

- Nanoscale (<100nm): shorter lithium-ion paths but prone to agglomeration;

- Microscale (>1μm): more stable cycling but lower energy density;

- Industry trend: using core–shell structures to achieve gradient particle distributions.

Performance Impact: Optimized particle size distribution can extend battery cycle life by over 2,000 cycles!

pH Value: The “Lifeline” of Chemical Stability

Definition: The slurry’s acidity or alkalinity, directly affecting the corrosion of current collectors (aluminum/copper foils).

Risks:

- Alkaline (pH >10): accelerates aluminum foil oxidation, raising internal resistance;

- Acidic (pH <5): corrodes copper foil, risking short circuits;

- Leading companies already control pH with ±0.1 precision.

User Warning: A battery with unstable pH may ignite or even “self-burn” while charging!

Impurity Content: The “Invisible Killer” of Safety

Definition: Residual metallic ions (Fe, Cu, Ni, etc.) and moisture (H2O) in slurry.

Hard Lessons:

- Just 1ppm of iron impurities can double self-discharge rates;

- Excess moisture causes electrolyte decomposition, generating gas and swelling;

- Tesla’s 4680 cells adopt “ultra-dry electrode” technology, keeping moisture below 10ppm.

Industry Benchmark: CATL uses magnetic separation to reduce metal impurities to as low as 0.3ppm.

Epic Powder

The five lithium battery slurry indicators define battery performance and safety. Behind them lies one core factor—powder grinding and classification technology.

With over 20 years of expertise in ultrafine powder processing, Epic Powder provides advanced ball mills, jet mills, and classifiers to precisely control particle size distribution, improve dispersion, and minimize impurities and moisture. Through customized solutions, Epic Powder is helping battery material manufacturers achieve high solid content, low impurity levels, and stable pH slurries—accelerating the deployment of next-generation high-energy-density batteries.