What Ceramic Materials are Needed to Produce a Lithium Battery?

With the continuous development of advanced technology, advanced ceramic powders and products have become key and bottleneck materials in certain high-tech fields. In the lithium

MQL jet mill is a Fluidised Bed Opposed Jet Mill with a built-in vertical classifying wheel. After the high-pressure air is filtered and dried, it is sprayed into the grinding chamber through multiple Laval nozzles at high speed. The material is brought to the intersection point by multiple high-pressure airflows, and is crushed by repeated collision, friction, and shearing. The ground material is pumped by the fan. Under the action, it moves to the classification area with the upward airflow, and under the action of the strong centrifugal force generated by the high-speed rotating classifying wheel, the coarse and fine materials are separated. The fine particles that meet the particle size requirements enter the cyclone separator and dust collector through the gap between the classifying wheel, and the coarse particles are collected. Descend to the grinding area to continue grinding.

Fluidized Bed Opposed Air Jet Mill: After the compressed air is filtered and dried, it is sprayed into the grinding chamber at high speed through the Laval nozzle. At the intersection of multiple high-pressure airflows, the materials are repeatedly collided, rubbed, and sheared to be crushed. The crushed materials rise with the suction of the fan. The airflow moves to the classification zone. Under the action of the strong centrifugal force generated by the high-speed rotating classification turbine, the coarse and fine materials are separated. The fine particles that meet the particle size requirements enter the cyclone separator and dust collector through the classification wheel for collection, and the coarse particles descend to the crushing zone and continue to be crushed.

| parameter/ Model | MQL03 | MQL06 | MQL010 | MQL20 | MQL30 | MQL40 | MQL60 | MQL80 | MQL120 | MQL160 | MQL240 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Feeding Size(mm) | <1 | <2 | <2 | <3 | <3 | <3 | <3 | <3 | <3 | <3 | <3 |

| Production Capacity(kg/h) | 1~10 | 10~150 | 20~300 | 40~600 | 100~900 | 200~1200 | 500~2000 | 800~3000 | 1500~6000 | 2000~8000 | 4000~12000 |

| Particle size(D97:μm) | 6~150 | 6~150 | 6~150 | 6~150 | 8~150 | 8~150 | 8~150 | 8~150 | 8~150 | 8~150 | 8~150 |

| Classifier motor (kw) | 4 | 4 | 5.5 | 7.5 | 7.5 | 11 | 18.5 | 18.5 | 30 | 45 | 55 |

| Air consumption(m³/min) | 3 | 6 | 10 | 20 | 30 | 40 | 60 | 80 | 120 | 160 | 240 |

| Air pressure(Mpa) | 0.6~1 | 0.6~1 | 0.6~1 | 0.6~1 | 0.6~1 | 0.6~1 | 0.6~1 | 0.6~1 | 0.6~1 | 0.6~1 | 0.6~1 |

Note: The production capacity is closely related to the particle size, specific gravity, hardness, moisture and other indicators of the raw materials. The above is only for selection reference.

With the continuous development of advanced technology, advanced ceramic powders and products have become key and bottleneck materials in certain high-tech fields. In the lithium

Why Choose Biomass as a Precursor? The shift toward Biomass-Derived Porous Carbon represents a critical evolution in materials science, moving away from non-renewable fossil sources

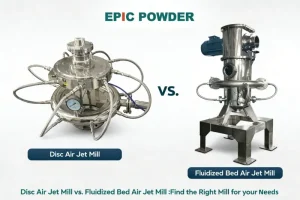

Conceptual Breakdown of Fluidized Bed Jet Mill vs. Disc Jet Mill In the realm of ultrafine powder processing, jet milling stands as a pivotal technology.

Understanding Petroleum Coke Characteristics Petroleum coke (petcoke) is a carbon-rich solid derived from the oil refining process. It features a high carbon content, low ash,

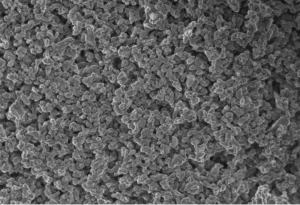

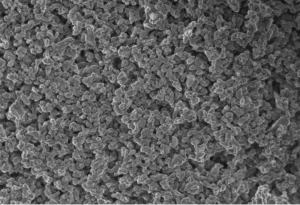

The Science Behind Particle Size and Morphology In my 20+ years of experience with powder processing, I’ve seen firsthand that raw chemical composition is only

In the production of lithium-ion batteries, the performance of cathode materials—such as lithium cobalt oxide (LCO), nickel–cobalt–manganese oxides (NCM), and lithium iron phosphate (LFP)—directly affects

Talc is unique among non-metallic minerals. It is the softest mineral on earth with a Mohs hardness of 1, but its true industrial value lies

Silicon–carbon (Si–C) anodes materials are regarded as one of the core enabling technologies for next-generation high-energy-density lithium-ion batteries. They are designed to overcome the intrinsic

WhatsApp us

Please fill in the form below.

Our experts will contact you within 6 hours to discuss your needs for machine and processes.