Project Background

A well-known chemical enterprise in Thailand is a leading local supplier of titanium dioxide (TiO₂, titanium white). As downstream industries such as coatings, plastics, and papermaking increasingly demand higher consistency in raw materials, the customer required Titanium Dioxide air classification with precise, high-frequency performance to process their coarse powder, ensuring that the final product’s particle size distribution (PSD) strictly meets specifications.

Core Requirements

- Material: Titanium Dioxide (TiO₂)

- Equipment Selection: HTS315-1 Horizontal Air Classifier

- Key Specification: Finished product fineness of D99 ≤ 53 μm

- Challenges: Titanium dioxide has strong adhesion and extremely high whiteness requirements; the equipment must prevent sticking and clogging while avoiding metal contamination.

After market research, the customer selected Epic Powder’s HTS series air classifier, known for high-efficiency classification and precise control.

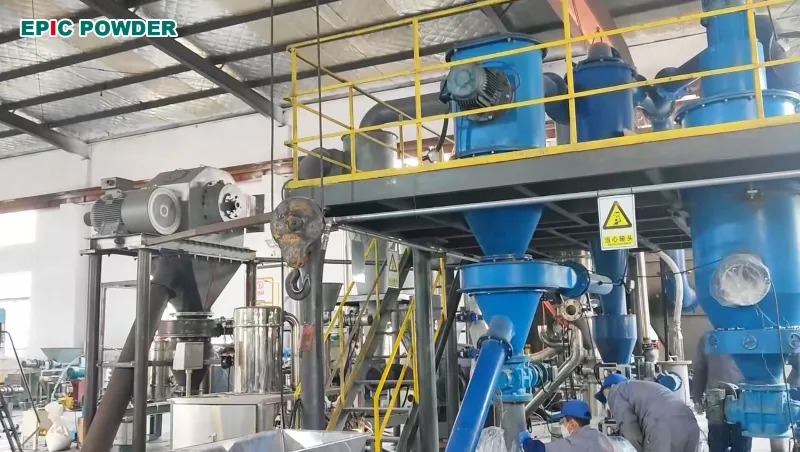

Equipment Selection: Epic Powder HTS315-1 Air Classifier

The HTS315-1 air classifier is a horizontal turbine classifier developed by Epic Powder, designed specifically for fine powder classification. Based on advanced aerodynamic principles, it uses a high-speed rotating turbine to generate centrifugal force and air drag, enabling precise particle separation.

Main Technical Parameters:

- Classifier wheel diameter: 315 mm

- Applicable materials: Titanium dioxide, calcium carbonate, quartz, and other non-metallic mineral powders

- Classification fineness range: D97 = 2–45 μm (adjustable); optimized to achieve D99 = 53 μm for this project

- Capacity: 0.5–5 t/h per unit, depending on material properties

- Power: 15 kW main motor; approximately 30 kW total system power

Key Features:

- Horizontal design with a small footprint, easy integration into existing production lines

- Multi-stage classification system ensuring high-precision separation, with coarse particle recovery >95%

- Built-in pulse dust collector, dust emissions <10 mg/m³, compliant with environmental standards

- PLC automatic control, supporting remote monitoring and parameter adjustment

In this project, the HTS315-1 was seamlessly integrated with the customer’s grinding and collection systems, forming a complete closed-circuit production line.

Project Implementation and Results

The project was officially commissioned in October 2025. After implementation, the following results were achieved:

- Particle size control: Laser particle size analysis showed stable product D99 of 50–53 μm, with uniformity improved by 30%

- Capacity increase: Hourly output reached 2.5 t/h per unit, a 50% increase compared with the previous equipment

- Energy savings: System energy consumption reduced to 0.15 kWh/kg, achieving 20% energy savings

- Environmental performance: Dust collection efficiency of 99%, no secondary pollution; certified by the Thailand Environmental Authority

- Economic benefits: Improved product quality enabled a 15% increase in market price, shortening the investment payback period to 18 months

Customer Feedback

The customer reported that the reliability and ease of maintenance of the HTS315-1 exceeded expectations. The titanium dioxide air classification system effectively eliminated production bottlenecks and supported the company’s transition toward higher-end markets.

“Thanks for reading. I hope my article helps. Please leave a comment down below. You may also contact Zelda online customer representative for any further inquiries.”

— Posted by Emily Chen