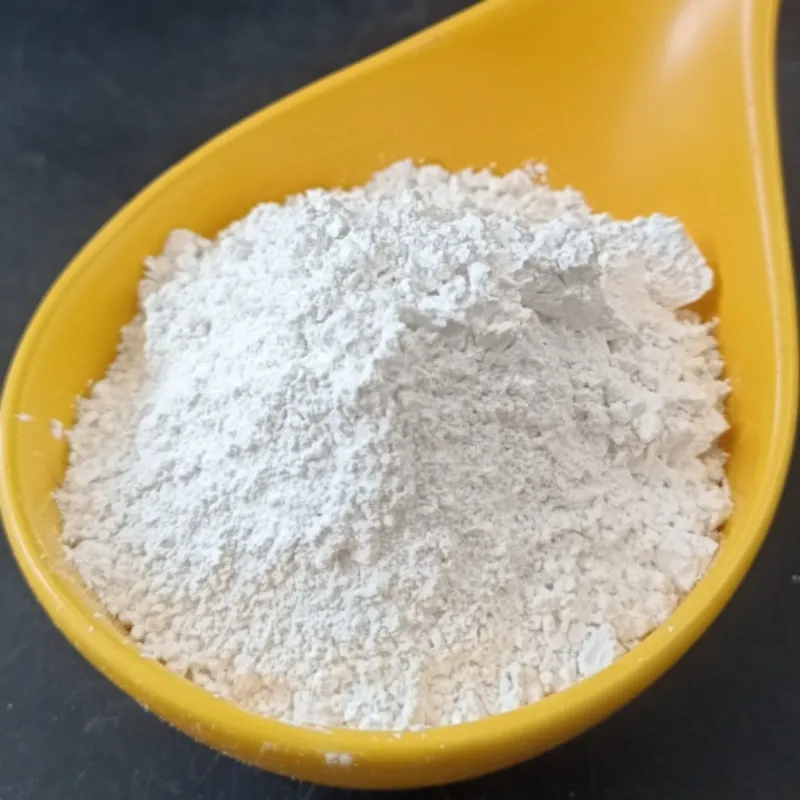

Talc, known for its softness and strong slippery feeling, is a hydrous magnesium silicate mineral with a layered structure. It mainly consists of magnesium silicate, aluminum oxide, nickel oxide, and other minerals. Talc powder, widely used in plastics, has excellent physical and chemical properties such as lubricity, anti-adhesion, flow aid, fire resistance, acid resistance, insulation, high melting point, chemical inertness, good coverage, softness, gloss, and strong adsorption. These characteristics make talc powder an ideal additive in various industries, including coatings, paints, plastics, paper, ceramics, cosmetics, pharmaceuticals, food, and daily supplies.

In plastics, talc powder significantly enhances certain properties of plastic products. When selecting talc powder for plastics, the following requirements should be carefully considered to ensure optimal performance and compatibility.

Purity

The higher the purity of talc powder, the better the enhancing effect. Metal impurities, especially iron, in talc powder have a significant impact on the anti-aging properties of plastics.

Structure

Talc powder usually comes in dense, flaky, radiating, or fibrous aggregates. Due to the layered crystalline structure of talc, it tends to split into scales, providing special lubrication.

High-quality ultrafine talc powder has a flaky structure. When used in plastics, it can evenly layer and disperse within the resin, providing good compatibility and complementary mechanical properties. Similar to a metal mesh embedded in cement products, it enhances the physical properties of plastics, offering thermal insulation and barrier effects while reducing production costs.

Wet Brightness and Hue

Mixing talc powder with plastics can alter the color of the plastic products to some extent. Dark-colored plastic products have fewer requirements for the whiteness of talc powder. However, for lighter-colored products, talc powder must have high wet brightness and a suitable hue.

Silicon Dioxide Content

The silicon (SiO2) content in talc powder is an important indicator of its grade. The higher the silicon content, the higher the purity and better the application performance of the talc powder, but the price will also be higher.

Customers should select talc powder based on the performance requirements of different plastic products. For example, in agricultural films, talc with higher silicon content and smaller particle size is preferred to improve the film’s light transmittance, tensile strength, and puncture resistance.

In injection molding, sheets, and rods, the silicon content requirement is lower. Talc with lower silicon content not only costs less but also improves the hardness and impact strength of plastic products.

Color

Raw talc powder can be white, gray, light red, pink, light blue, light green, etc. It also has a special silvery or pearlescent appearance with varying degrees of gloss. This color improves the appearance and visual effects of products.

Surface Properties

Talc powder exhibits different surface properties depending on its source. The specific surface area and oil absorption rate largely depend on the mineral resource and product fineness. Other factors influencing these properties include surface roughness, particle shape, and pore volume.

Talc powder’s large specific surface area and appearance structure can improve resin binding and enhance the physical properties of plastic products.

Moisture

The structural form of talc powder determines its characteristics. Though hydrophobic, talc powder contains both structural water and crystallization water due to the irregularity of its particle edges. As a result, it has higher moisture content than calcium carbonate.

Moisture can significantly affect the performance of plastics, so the moisture content of talc powder should be carefully controlled through drying processes.

Static Electricity

Talc powder, with its layered structure and large specific surface area, tends to generate static electricity due to its irregular particle shape and surface morphology. This can cause aggregation between small particles, making dispersion difficult and affecting its application.

Flowability

During extrusion, talc powder’s flaky structure impairs flowability compared to other particulate inorganic materials. It disperses poorly, causing high torque in the main screw. Proper activation and coating are key to overcoming these issues.

Epic Powder

Epic Powder, with its advanced grinding and processing equipment, ensures the production of high-quality talc powder with controlled particle size, purity, and moisture content. Our precision grinding solutions enhance talc’s compatibility and performance in plastics, contributing to improved product quality, cost reduction, and overall efficiency.