Applications in the Pharmaceutical Industry

Enhancing Solubility and Bioavailability

Ultrafine grinding technology reduces active pharmaceutical ingredients into submicron or nanometer-sized particles. This dramatically improves solubility and absorption efficiency, leading to faster and more consistent therapeutic effects.

Improving Uniformity and Stability

By precisely controlling particle size distribution, ultrafine grinding ensures better uniformity of pharmaceutical materials, resulting in stable release and enhanced formulation stability.

Supporting New Formulation Development

Ultrafine grinding enables researchers to design new formulations with optimized particle size and morphology, which is essential for controlled release and targeted delivery systems.

Applications in the Chemical Industry

Production of Fine Chemicals and Catalysts

Ultrafine grinding increases the surface area and reactivity of chemical materials, improving the catalytic activity and selectivity of reactions.

Preparation of High-Performance Materials

In the chemical field, ultrafine grinding is used to produce nanomaterials and specialty ultrafine powders with excellent dispersion, thermal stability, and conductivity—applied in batteries, pigments, and advanced coatings.

Enhancing Product Quality and Value-Added

By achieving finer and more uniform particle sizes, product quality, performance, and added value are greatly improved, meeting market demand for high-performance functional materials.

Recommended Equipment & Particle Size:

- Equipment: Ball Mill + Air Classifier System, Jet Mill, Pin Mill

- Typical Particle Size: D50 = 3–10 μm; D97 ≤ 20 μm

- Advantages: Stable and continuous operation, suitable for inorganic salts, oxides, catalysts, and chemical additives

Applications in the Food Industry

Production of Ultrafine Food Powders

Ultrafine grinding is widely used in producing high-value food powders such as protein powder, milk powder, flour, and tea powder. The finer particle size enhances solubility, mouthfeel, and nutrient absorption.

Improving Processing Performance

By reducing particle size, the water absorption, mixing uniformity, and stability of food materials can be improved, enhancing product consistency and processing efficiency.

Development of Functional Foods and Health Products

Ultrafine grinding enables the creation of food products with specific nutritional or functional properties, supporting innovation in the health food and supplement sectors.

Recommended Equipment & Particle Size:

- Equipment: Mechanical Impact Mill, Air Classifier Mill, Pin Mill

- Typical Particle Size: D50 = 10–50 μm; D97 ≤ 100 μm

- Advantages: Gentle grinding, preserving aroma and nutrients, suitable for organic and natural materials

Applications in the Mineral Industry

Production of High-Purity Mineral Powders

Ultrafine grinding technology is widely applied in non-metallic mineral processing, such as calcium carbonate, quartz, talc, kaolin, mica, feldspar, and silica.

By precisely controlling particle size, whiteness, and purity, it meets the demanding requirements of plastics, coatings, ceramics, and new materials industries.

Improving Mineral Powder Reactivity and Surface Activity

Ultrafine grinding increases the specific surface area of mineral powders, enhancing surface activation and improving compatibility with polymers and resins after surface modification.

Enabling High-Value Mineral Applications

Through ultrafine grinding, traditional minerals can be transformed into high-value functional powders — for instance, nano calcium carbonate in plastics, ultrafine silica in lithium batteries, or superfine talc in cosmetics.

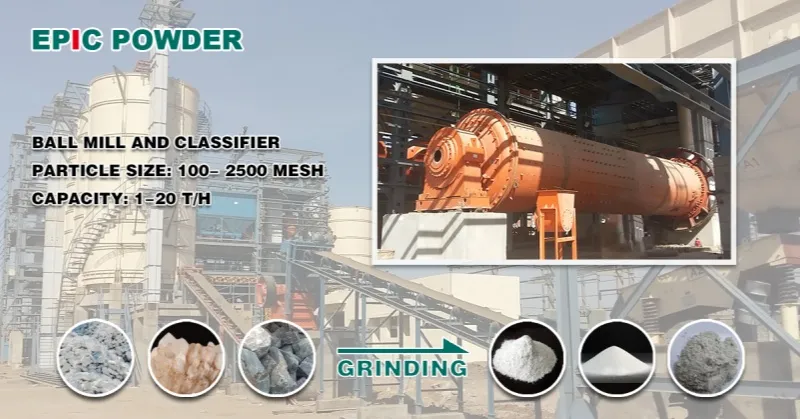

Recommended Equipment & Particle Size:

- Equipment: Ball Mill + Classifier System, Jet Mill, Vertical Roller Mill, Stirred Mill

- Typical Particle Size:

- Heavy Calcium Carbonate: D97 = 5–10 μm

- Kaolin, Talc: D97 = 3–8 μm

- Quartz, Silica Powder: D97 = 2–5 μm

- Advantages: Large-scale continuous production, narrow particle size distribution, high purity, suitable for mineral grinding and classification

How to Choose Suitable Ultrafine Grinding Equipment

Consideration of Material Characteristics

Hardness and Brittleness:

The mechanical properties of materials directly affect grinding efficiency and equipment wear. Hard and brittle materials (e.g., quartz, alumina) require jet mills or ball mills with wear-resistant linings.

Moisture and Adhesiveness:

Materials with high moisture or stickiness (e.g., sugar, protein, clay) should use drying-type or low-temperature systems to prevent agglomeration and blockage.

Chemical Properties:

Some active or reactive materials may oxidize or decompose during grinding. Equipment made from inert materials such as ceramics or stainless steel should be used to ensure purity and stability.

Consideration of Production Capacity

Production Scale:

Select suitable models for laboratory, pilot-scale, or large-scale production to ensure efficiency and economic performance.

Equipment Capacity:

The chosen ultrafine grinding system should have sufficient throughput to avoid overload, ensuring stable continuous operation.

System Configuration:

Equip the system with proper feeding, grinding, classification, and collection modules for efficient, clean, and safe production.

Consideration of Particle Size Requirements

Particle Size Distribution:

Each application requires a specific range of particle sizes. Choose equipment that ensures narrow and consistent distribution.

Particle Size Control:

Select systems with adjustable grinding energy and precise classifier control to achieve target particle sizes.

Real-Time Particle Size Detection:

Advanced systems with in-line particle size analysis allow real-time adjustments, ensuring product quality consistency.

Conclusion

EPIC Powder specializes in customized ultrafine grinding and classification solutions for diverse industries — including pharmaceuticals, chemicals, mineral and food.

With over 20 years of expertise, EPIC provides a full range of systems such as Jet Mills, Ball Mill–Classifier Systems, and Air Classifier Mills, tailored to specific material properties and product goals.

Whether your goal is nanometer precision, contamination-free processing, or large-scale continuous production, EPIC’s engineering team can deliver reliable, efficient, and high-purity solutions to meet your industrial needs.

“Thanks for reading. I hope my article helps. Please leave me a comment down below. You may also contact Zelda on Line customer representative for any further inquiries.”

— Posted by Emily Chen