Choosing the appropriate dispersant to prevent the ultrafine powder agglomeration requires a comprehensive consideration of powder properties, dispersing medium, and processing conditions. The following are key principles and strategies:

Select the Dispersant Type According to The Powder Characteristics

Surface Charge and Polarity Matching

Polar powders (such as ceramics, oxides): Prefer anionic dispersants (e.g., sodium polyacrylate, sodium hexametaphosphate) to prevent the ultrafine powder agglomeration through electrostatic repulsion. For example, ZnO is stably dispersed at pH = 5 via double-layer repulsion.

Non-polar powders (such as graphene, carbon black): Use non-ionic dispersants (e.g., PVP, PEG) to prevent contact through steric hindrance. For high surface energy materials (e.g., nano-silicon carbide), combine in-situ functionalization (e.g., silane coupling agents) to enhance adsorption strength.

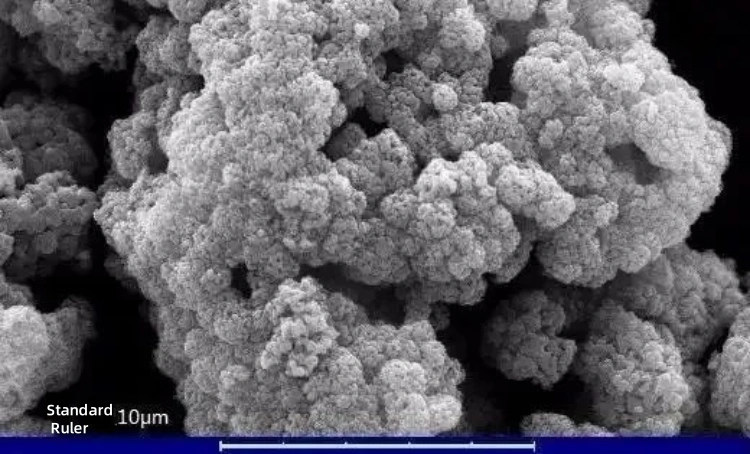

Particle Size and Specific Surface Area

Nanopowders (<100 nm): Use low molecular weight dispersants (e.g., ammonium oleate, titanates) to minimize interference from steric layers, combined with dynamic processes (e.g., ultrasonic assistance) to maintain dispersion.

Micropowders: High molecular weight dispersants (e.g., block copolymers) are more effective, forming a dense barrier through long-chain adsorption.

Dispersion Medium and System Environment Adaptation

Aqueous System

High polarity media: Choose carboxylates (e.g., DA dispersant) or phosphates (e.g., sodium pyrophosphate) to use electrostatic double-layer repulsion. For example, zirconium silicate is uniformly dispersed using sodium silicate dispersant at pH = 7.

Electrolyte-containing systems: Add salt-resistant dispersants (e.g., polyether-modified siloxanes) to prevent high ion strength from compressing the double layer.

Non-aqueous or Oily Systems

Organic solvents (e.g., ethanol, acetone): Use hydrophobic chain dispersants (e.g., phosphates, sodium oleate) to adsorb particles via hydrophobic interactions. For example, carbon black in ink is often dispersed with polyoxyethylene ether dispersants.

pH-sensitive Systems

Adjust the pH to optimize dispersant adsorption. For example, aluminum oxide is dispersed in alkaline conditions using triethanolamine, where its hydroxyl groups form a stable hydrated layer with the particle surface.

Dispersant Performance and Dosage Optimization

Adsorption Strength and Stability

Choose dispersants that match the functional groups on the powder surface (e.g., carboxyl groups for metal oxides). For example, graphene forms stable adsorption with PVP after grafting carboxyl groups via oxidation-reduction.

For high-temperature systems (e.g., refractory materials), select thermally stable dispersants (e.g., titanates, zirconium aluminate) that maintain the adsorption layer intact at 500°C.

Amount Control

The typical dispersant dosage is 0.5%–3% of the powder mass. Ultrafine powders require higher dosages due to their larger specific surface area, but excess amounts should be avoided as they can increase system viscosity or degrade performance. For example, using more than 5% dispersant for nano-SiO₂ in epoxy resin can reduce coating strength.

Blending Synergy Strategies

Physical-Chemical Combination: Use ultrasonic pre-dispersion (to break hard agglomerates) combined with dispersant adsorption (to maintain stability). For example, diamond micro-powder achieves a 60% improvement in dispersion efficiency after ultrasonic treatment followed by adding sodium polyacrylate.

Multi-component Blending: Mix dispersants with different molecular weights (e.g., PEG 200 and PEG 4000 in a 5:1 ratio) to optimize particle size distribution. For example, ultrafine barium sulfate is dispersed with a blend of polyethylene glycol for a narrow distribution.

Application Scenario Adaptation and Process Linkage

Dry Dispersion Systems

Use electrostatic dispersion (e.g., corona charging) or fluidized bed technology. The dispersant should have anti-static properties. For example, ultrafine coal powder dispersion improves by 40% under a voltage of 30-50 kV.

Wet Grinding and Slurry Systems

Select grinding aid dispersants (e.g., ammonium polyacrylate) based on grinding processes (e.g., sand mill, ball mill) to reduce slurry viscosity. For example, adding 0.5% dispersant during ceramic binder ball milling reduces agglomerate size to 0.186 μm.

High-Temperature Sintering or Drying Processes

For freeze-drying or spray drying, choose degradable dispersants (e.g., starch derivatives) to reduce residue impact. For example, nano-aluminum oxide prevents hard agglomeration during freeze-drying.

Verification and Optimization

Real-Time Monitoring

Use laser particle size analyzers and Zeta potential meters to evaluate dispersion effects and adjust dispersant types and quantities. For example, ATO slurry shows the best dispersion at pH=11 when the absolute value of the Zeta potential is maximal.

Compatibility Testing

Evaluate the impact of dispersants on the final product’s properties, such as conductivity and transparency. For example, PVP residue can increase the resistivity of conductive slurry by 20%, requiring a low-residue dispersant.

Conclusion

The selection of dispersants should focus on the interplay of powder, medium, and process to prevent ultrafine powder agglomeration. Prioritize matching surface properties with system polarity, optimize adsorption stability via dynamic processes, and ensure long-term dispersion through blending and real-time monitoring.

Epic Powder

Epic Powder, 20+ years of work experience in the ultrafine powder industry. Actively promote the future development of ultra-fine powder, focusing on crushing,grinding,classifying and modification process of ultra-fine powder. Contact us for a free consultation and customized solutions! Our expert team is dedicated to providing high-quality products and services to maximize the value of your powder processing. Epic Powder—Your Trusted Powder Processing Expert !