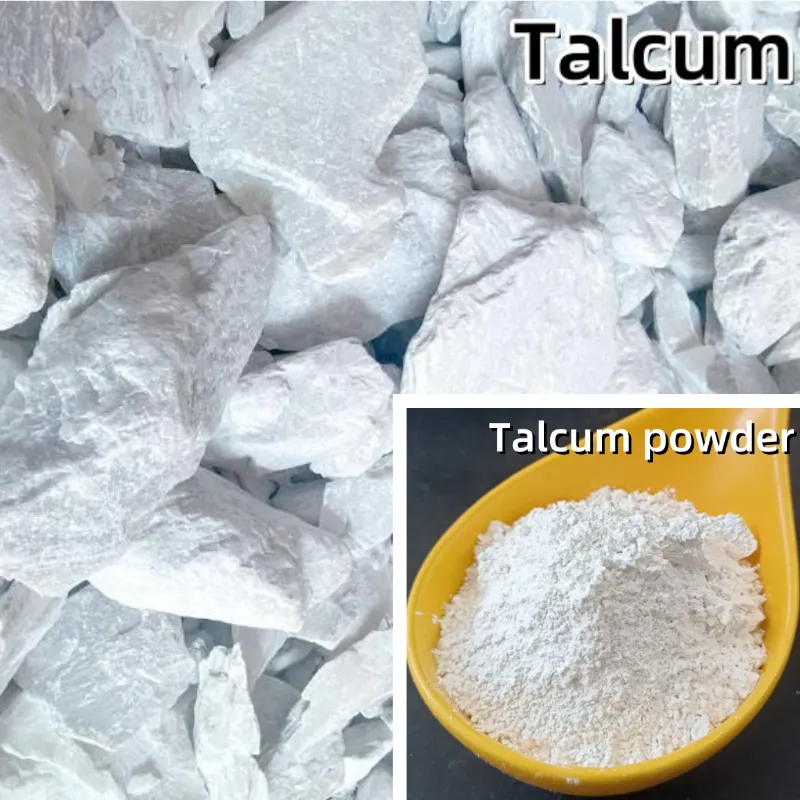

Talc powder is one of the most widely used and cost-effective functional fillers in the coatings industry. Its main component is hydrated magnesium silicate, with the chemical formula 3MgO·4SiO₂·H₂O, belonging to the monoclinic crystal system. It typically appears as pseudo-hexagonal or rhombohedral plate-like crystals.

High-quality talc powder is white or off-white. It has a smooth, silky feel and exhibits excellent physical and chemical properties. These include:

- Good lubricity.

- High refractoriness.

- Acid and alkali resistance.

- Strong insulation.

- A high melting point (about 1500°C).

- Chemical inertness.

- Strong hiding power.

- Outstanding adsorption capacity.

In recent years, thanks to advances in ultra-fine grinding, classification, and surface modification technologies, talc powder has expanded from traditional solvent-based coatings to water-based, powder, and high-solids coatings. It is now widely used in architectural coatings, industrial anti-corrosion coatings, road marking paints, automotive paints, wood coatings, and coil coatings.

Performance of Talc Powder in Coatings

Leveraging its unique crystal morphology and intrinsic properties, talc powder plays a crucial role in various types of primers, intermediate coatings, industrial coatings, road marking paints, and interior/exterior wall coatings.

Performance Differences from Crystal Morphology

| Crystal Form | Key Properties | Typical Applications & Effects |

|---|---|---|

| Plate-like talc powder | Excellent brushing properties, film flow and smoothness, water resistance, and prevention of enamel penetration. | Used in primers and intermediate coatings (steel structure primers, anti-corrosion coatings). Effects: Enhances sedimentation stability, mechanical strength, and recoatability; in anti-corrosion systems, it lengthens the diffusion path of corrosive media, improving protection. |

| Fibrous talc powder | Higher oil absorption and excellent rheology. | Used to improve application properties. Effects: Prevents sedimentation during storage, improves sagging resistance during brushing, and enhances overall application performance. |

Adjusting Coating Performance Through Particle Size & Modification

Talc powder used in coatings is classified into several grades according to particle size:

325 mesh, 20 µm, 10 µm, 5 µm ultra-fine, nano-grade, and surface-modified talc powder.

- Coarse grades: For applications requiring slightly rough film appearance, such as intermediate layers of interior primers and textured coatings.

- Fine and ultra-fine grades: Regulate gloss, viscosity, and sag resistance in semi-gloss enamel and various coatings. They also provide a “spatial isolation effect”, allowing partial replacement of TiO₂.

- Modified talc powder: Further enhances compatibility, improves coating rheology, reduces viscosity fluctuations, and lowers application difficulty.

Partial TiO₂ Replacement:

Ultra-fine talc powder (D97 ≤ 5 μm) and modified talc powder help disperse TiO₂ particles, reduce agglomeration, and improve TiO₂ efficiency by 10–25%, offering excellent cost-performance in semi-gloss and matte coatings.

Enhancing Specific Coating Systems

Talc powder is especially suitable for PU, PE, UV, and NC coatings, offering benefits such as:

- Enhanced primer transparency and recoatability

- Higher filling efficiency and lower cost

- Improved appearance and higher solid content

- Better sanding performance of primer films

Common Specifications & Selection Principles

| Grade | D97 | Whiteness | Oil Absorption (g/100g) | Main Applications |

|---|---|---|---|---|

| 325 mesh | ≤45 μm | 85–90 | 28–35 | Interior wall putty, general primers |

| 1250 mesh | ≤10 μm | 90–94 | 32–40 | Industrial coatings, road marking paints |

| 2000–3000 mesh | ≤5–3 μm | 92–96 | 35–45 | Automotive intermediate coats, coil coatings, semi-gloss paints |

| 5000 mesh + modified | ≤2.5 μm | 93–97 | 22–30 (after modification) | High-end water-based architectural coatings, partial TiO₂ replacement |

Preparation and Grinding of Talc Powder

The preparation of talc micropowder is critical to determining its performance in coatings. High-quality talc powder is produced through raw material selection, washing, drying, grinding, and classification.

Main Grinding & Processing Equipment

1. Crushing & Pre-treatment

Large talc blocks are pre-crushed using jaw crushers or hammer crushers.

2. Fine Grinding

Depending on the required fineness, different grinding systems are used:

- Jet Mill: Produces ultra-fine talc (5 μm or finer), even nano-grade; narrow particle size distribution; best for high-end coatings, but high energy consumption.

- Raymond Mill / Vertical Mill: Suitable for 325-mesh to fine-grade products; high capacity but limited ultra-fine capability.

- Stirred Mill / Vibration Mill: Effective for dry or wet ultra-fine grinding; capable of producing finer products.

3. Precision Classification

High-precision air classifiers ensure that the final product meets strict fineness requirements for different coating applications.

4. Surface Modification (Optional)

Used to improve dispersibility, reduce oil absorption, and enhance compatibility.

Common modifiers include:

- Silane coupling agents, titanates

- Stearic acid, oleic acid

- Amino silicone oil, organosilicone (for water-based hydrophobicity)

After modification, activation can reach >95%, oil absorption significantly decreases, and TiO₂ replacement can reach 10–30%.

Conclusion

As the coating industry demands higher fineness and better dispersion, talc processing continues to improve. The industry also needs more stable coating systems. As a result, talc production is becoming more precise and consistent.

Epic Powder has over 20 years of experience in ultra-fine powder processing.

The company offers complete talc grinding solutions. These include ball mills, vertical mills, impact mills, jet mills, and high-precision classifiers. The systems ensure stable production from 325 mesh to 5 μm. They also help preserve the desirable plate-like structure of talc.

Epic Powder provides high efficiency and low energy consumption. It also delivers fully customizable engineering solutions. With these strengths, Epic Powder supports coating manufacturers worldwide. The company helps improve product performance and maintain competitiveness.

“Thanks for reading. I hope my article helps. Please leave a comment down below. You may also contact Zelda online customer representative for any further inquiries.”

— Posted by Emily Chen