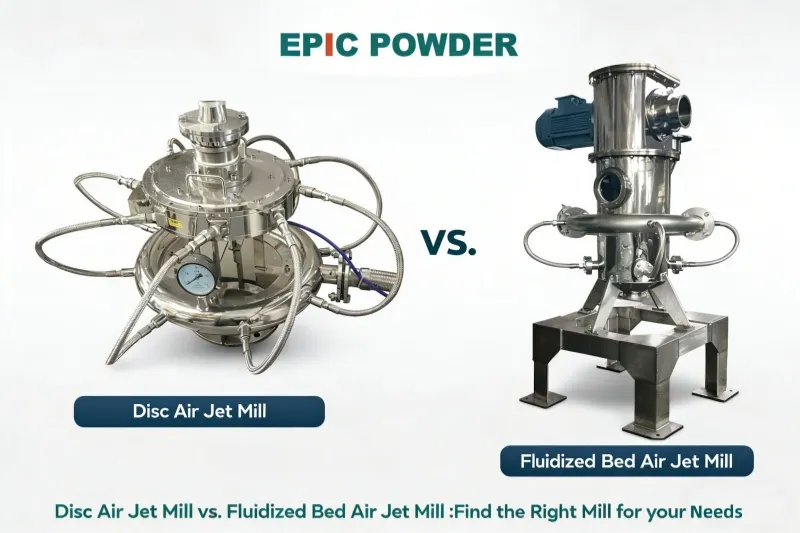

Conceptual Breakdown of Fluidized Bed Jet Mill vs. Disc Jet Mill

In the realm of ultrafine powder processing, jet milling stands as a pivotal technology. It is widely used for achieving particle sizes in the micron and sub-micron range. Among the various configurations, the Fluidized Bed Air Jet Mill and the Disc Air Jet Mill (also commonly referred to as a Flat Jet Mill or Spiral Jet Mill) are two of the most prevalent and technologically distinct systems. The topic of Fluidized Bed Jet Mill vs Disc Jet Mill has therefore become central to equipment selection and process optimization in modern powder engineering. A thorough performance comparison necessitates first understanding their fundamental principles and design philosophies.

Fluidized Bed Air Jet Mill:

This system is characterized by its use of high-speed air jets to create a “fluidized bed” of material particles within the grinding chamber. The core principle involves multiple nozzles, typically three or four. These nozzles are arranged around the perimeter of the grinding chamber. They inject filtered, dried, and compressed air at supersonic speeds.

These opposing jets intersect at a central point inside the chamber. The material particles are rapidly accelerated. Violent inter-particle collisions occur as a result. The kinetic energy from these inter-particle collisions achieves comminution. A key integrated component is a high-speed, horizontal turbine classifier wheel located above the grinding zone. The ground material is carried upward by the air stream to this classifier, where centrifugal force separates coarse particles (which return to the grinding zone) from fine particles that meet the size specification and proceed to the collection system. This design inherently operates under negative pressure, ensuring a dust-free and clean process.

Disc Air Jet Mill (Flat/Spiral Jet Mill):

This mill operates on a different mechanical principle. Here, the grinding chamber is typically a flat, cylindrical space. Compressed air is introduced through several nozzles installed tangentially to the chamber wall. The material is fed into this chamber and entrained by the high-speed, spiraling vortex of air. The primary grinding mechanism is the impact and attrition caused by particles colliding with the chamber’s inner wall or liner and with each other within the swirling flow. Classification often occurs via an internal centrifugal mechanism or through the spiral flow itself, where coarser particles are forced to the periphery while finer ones move toward the center for extraction. Traditionally, these mills often operate under positive pressure, though modern designs may incorporate exhaust systems.

The fundamental divergence between these two technologies lies in their primary grinding action.

- Fluidized Bed Mill: This system relies on particle-on-particle collision (self-attrition). The process occurs within a controlled zone where accelerated jets intersect.

- Disc Mill: In contrast, this design relies more on particle-wall collision. The grinding takes place within a high-velocity centrifugal air vortex.

This core difference in mechanics leads to a cascade of variations in performance. Specifically, it affects wear rates, contamination risks, and energy efficiency. It also dictates particle shape control and general operational characteristics. These factors together form the basis for a detailed performance comparison.

Two Related Questions and Answers

Question 1: What is the most significant performance difference stemming from their distinct grinding mechanisms, and how does it affect long-term operational costs and product purity?

Answer: The most profound difference is the wear pattern and its consequences. In a Fluidized Bed Air Jet Mill, the grinding process is completed by the collision of the materials themselves—fully self-grinding. Since the particles rarely collide with the chamber walls, wear on the equipment’s internal surfaces is minimal. This makes it exceptionally suitable for grinding materials with high hardness (Mohs hardness up to 9). Furthermore, to achieve ultimate product purity, key components like the inner liner, classifying wheel, and nozzles can be lined with or made from ceramic materials (e.g., aluminum oxide, zirconium oxide, silicon carbide), ensuring non-contact with metal throughout the entire grinding process. This results in extremely low contamination risk, a critical factor for pharmaceuticals, high-purity ceramics, and battery materials.

In contrast, the Disc Jet Mill subjects its chamber walls to direct and continuous impact from high-speed particles. This leads to noticeable wear on the inner liner or wall, which can cause material contamination and necessitates regular liner replacement. Consequently, while the initial capital cost of a disc mill might be lower, the long-term operational costs can be higher due to spare parts (liners) and potential costs associated with product contamination or more frequent maintenance intervals. For applications demanding high product purity or involving very abrasive materials, the fluidized bed design offers a clear performance advantage in terms of durability and contamination control.

Question 2: How do the two mill types differ in controlling final particle size distribution and handling heat-sensitive materials?

Answer: They differ significantly in granularity control precision and heat management.

Particle Size Control: The Fluidized Bed Air Jet Mill offers superior and more precise control over the final particle size distribution (PSD). This is achieved through its integrated, high-speed turbine classifier. The particle size is controlled by adjusting the rotational speed of this classifier wheel; a higher speed creates greater centrifugal force, allowing only finer particles to pass, resulting in a narrow, tightly controlled PSD. This “built-in self-diverting micronizer” ensures a concentrated distribution with no oversized particles. The Disc Jet Mill, however, often relies on adjusting the feed rate and the inherent dynamics of the spiral airflow for classification, which offers less precise and stable control over the final PSD. Its particle size distribution can be broader and less easily fine-tuned.

Heat Sensitivity: Both mills are generally considered suitable for low-temperature, medium-free grinding, which is beneficial for heat-sensitive materials. The expansion of compressed gas (air or inert gas) as it exits the nozzles causes adiabatic cooling, which helps keep the grinding chamber temperature low. However, the fluidized bed mill often has an edge in this aspect. Its self-attrition grinding mechanism generates less frictional heat compared to the intense particle-wall friction in a disc mill. The entire grinding process is also typically a negative pressure system, promoting consistent airflow and heat dissipation. Furthermore, for extremely sensitive or explosive materials, the fluidized bed mill can be more easily adapted to a fully closed-loop inert gas (like nitrogen) circulation system, where the gas is recycled with minimal loss, maintaining a safe, oxygen-free environment. This makes it particularly suitable for pharmaceuticals, volatile compounds, and flammable chemicals.

Performance Comparison: Fluidized Bed Jet mill vs. Disc Air Jet Mill

A detailed performance comparison between Fluidized Bed Air Jet Mills and Disc Air Jet Mills is not merely an academic exercise. It is a critical decision-making step for fine powder manufacturers, carrying significant practical and economic weight.

Informed Investment and TCO Analysis

It is vital to avoid selecting the wrong model based solely on the initial purchase price, as Disc mills often appear cheaper upfront. A holistic evaluation provides a realistic assessment of the Total Cost of Ownership (TCO). This analysis accounts for energy consumption—where Fluidized Bed mills can save 30–40%—as well as the cost of wear parts, maintenance downtime, and overall product yield.

Optimization of Process Efficiency and Product Quality

Choosing the right mill depends on matching the equipment to material characteristics, such as hardness and abrasiveness. It also must meet specific product requirements like purity, Particle Size Distribution (PSD), and throughput.

- Fluidized Bed Mills: Best for high-purity, narrow-distribution, and highly abrasive materials (e.g., Zirconia), especially when equipped with ceramic linings.

- Disc Mills: May be more cost-effective for materials with low abrasivity and high volume requirements.

The correct choice directly improves production capacity and consistency. Furthermore, it ensures regulatory compliance. In the pharmaceutical sector, for instance, the “dead-zone-free” design of Fluidized Bed mills is a major advantage for GMP standards.

Risk Mitigation and Future-Proofing

A systematic comparison helps identify potential issues early. These include dust leakage, contamination risks, and safety hazards for explosive materials. It also helps spot bottlenecks during production scale-up. This proactive approach reduces unplanned shutdowns and safety risks while ensuring the technology can adapt to future product lines.

Fostering Innovation and Strategic Vendor Partnerships

The comparison process encourages buyers to demand empirical test data and tailored solutions from suppliers. This moves the conversation beyond generic marketing claims. Ultimately, this deepens the buyer’s understanding of powder technology. It also adds value through customized design, better installation, and superior operator training, leading to long-term process improvements.

A Step-by-Step Guide to Conducting the Performance Comparison

A rigorous comparison should be a multi-stage, data-driven process. Here is a detailed step-by-step methodology:

Step 1: Define Comparison Objectives and Material Characterization

Clearly articulate the goal. Is it for a new product line, replacement of old equipment, or capacity expansion? Then, meticulously characterize your material(s):

Physical Properties: Mohs hardness, density, moisture content, feed particle size (<3mm is typical).

Chemical Properties: Heat sensitivity, melting point, flammability, explosiveness, oxidation tendency, sugar/volatile content.

Target Product Specifications: Required final particle size (D50, D97, e.g., 1-45µm) and distribution width, desired particle shape (sphericity), maximum allowable contamination (e.g., iron content), and required production capacity (kg/h).

Step 2: Analyze Key Performance Indicators (KPIs) for Each Mill Type

Create a comparison matrix based on the following KPIs, using information gathered from technical literature and supplier consultations:

Grinding Mechanism & Wear: Contrast self-attrition (fluidized bed) vs. particle-wall impact (disc). Note the implications for liner wear and material of construction options (metal vs. ceramic).

Particle Size Control & Shape: Evaluate the precision of the classification system (adjustable classifier wheel vs. airflow/feed rate adjustment). Consider which system better preserves original particle shape.

Energy Efficiency: Compare specific energy consumption (kWh/kg). Data suggests fluidized bed mills can be 30-40% more efficient. Request specific air consumption (m³/min) and installed power (kW) for comparable models from suppliers.

Contamination & Purity: Assess the risk of metallic contamination from wear. The possibility of full ceramic contact parts is a major advantage for fluidized bed mills in high-purity applications.

System Design & Operation: Compare negative pressure (clean, dust-free) vs. traditional positive pressure operation. Evaluate ease of cleaning, changeover time between products, and compliance with standards like GMP. Consider the footprint and layout flexibility.

Material Suitability: Map your material characteristics from Step 1 against each mill’s strengths. Fluidized bed excels with hard, high-purity, heat-sensitive, and explosive materials. Disc mills are often applied for a wide range of general materials where extreme control is less critical.

Step 3: Gather Objective Data: Technical Proposals and Material Testing

Contact shortlisted suppliers of both mill types (e.g., manufacturers like Epic Powder etc.). Provide them with your material samples and target specifications.

Request Detailed Proposals: Ask for technical data sheets specifying model numbers, capacities, air consumption, power requirements, and offered configurations for your specific material. Note that capacity is highly material-dependent.

Insist on Material Trial Tests: The most critical step. Utilize the suppliers’ test stations. Have them process your sample in both types of mills (if possible). Analyze the trial products for: actual particle size distribution (PSD), particle morphology (using microscopy), contamination levels, and residual moisture or heat damage. Also, note the observed throughput during the trial.

Step 4: Comprehensive Evaluation and Decision Making

Synthesize all information:

Technical Fit: Which mill consistently met your product specs in trials?

Economic Analysis: Calculate TCO. Factor in: Quoted equipment price, estimated energy costs (based on air consumption and compressor power), cost of spare parts/liners over 5 years, and estimated maintenance labor.

Operational & Safety Fit: Which system integrates better into your plant layout and workflow? Which one offers safer operation for your operators and material?

Supplier Assessment: Evaluate the support offered (engineering, installation, training, warranty) and the supplier’s reputation.

Based on this weighted analysis, a clear frontrunner should emerge. The decision should balance technical superiority with economic practicality.

Practical Application Cases and Results

The theoretical comparison comes to life through practical application. Here are illustrative cases based on common industry needs:

Case 1: Production of High-Purity Ceramic Powder for Electronics

Objective: Produce aluminum oxide (Al₂O₃, Mohs ~9) powder with a D97 < 10µm, with strict limits on metallic contamination (iron < 50 ppm).

Comparison & Result: A disc mill would cause rapid wear of its metal liner, inevitably contaminating the product with iron and requiring frequent, costly liner changes. A fluidized bed jet mill with a fully ceramic grinding chamber (liner, classifier, nozzles) was selected. The self-attrition grinding minimized wear on the ceramic itself. The result was a consistent product meeting the stringent purity specifications, with virtually no measurable iron contamination. The liner life extended to several years, making the higher initial investment in the ceramic-lined fluidized bed mill far more economical over time, while guaranteeing product quality.

Case 2: Micronization of a Heat-Sensitive Active Pharmaceutical Ingredient (API)

Objective: Reduce the particle size of an API to D50 ~ 5µm to enhance bioavailability. The API degrades above 40°C.

Comparison & Result : Both mills advertise low-temperature grinding. Trials were conducted. The disc mill relies heavily on friction. Consequently, it showed a slight temperature rise in the product collection bag. At high feed rates, this temperature approached the API’s safety limit. In contrast, the fluidized bed mill maintained product temperature consistently at ambient levels, even at higher throughputs. This was achieved through more efficient cooling from adiabatic expansion and negative pressure flow. Furthermore, its fully enclosed, easy-clean design simplified the validation process for GMP compliance.

The Result: The fluidized bed mill was selected. It provided a larger operational window and easier regulatory compliance, ensuring no thermal degradation of the valuable API.

Case 3: High-Volume Processing of a Soft Mineral Filler

Objective: Increase production capacity for grinding calcium carbonate (Mohs ~3) from 1000 kg/h to 3000 kg/h, targeting a D97 of 45µm.

Comparison & Result: The material is not abrasive, not heat-sensitive, and high purity is not the primary concern. The key driver is throughput per capital and energy cost. A large disc mill system (e.g., MQP60/80 series) and a large fluidized bed mill (e.g., SCWN-Q600) were quoted. The disc mill offered a slightly lower initial purchase price and a proven, simple design for this application. The fluidized bed mill promised better energy efficiency. A TCO analysis over five years revealed a different outcome for this specific application. Despite its efficiency, the energy savings of the fluidized bed mill did not fully offset its higher initial cost.

The Result: The disc mill was selected. It met the capacity requirements reliably at a lower overall project cost. This case demonstrates that the “technologically superior” option is not always the most economical for every application.

Conclusion

Evaluating the performance of Fluidized Bed Jet Mill vs. Disc Air Jet Mill is not about declaring a universal winner. Instead, it is about intelligently mapping their distinct performance profiles against specific needs. These profiles include fundamental grinding mechanics, wear resistance, precision control, and operational safety. These factors must be weighed against the unique tapestry of material properties, product specifications, and economic constraints. A disciplined, step-by-step comparison is essential. When crowned by practical material testing, this approach is the only reliable path to selecting the optimal technology. Ultimately, the right choice ensures quality, efficiency, and profitability in the demanding world of ultrafine powder production.

“Thanks for reading. I hope my article helps. Please leave a comment down below. You may also contact Zelda online customer representative for any further inquiries.”

— Posted by Emily Chen