In the field of powder materials, white carbon black (precipitated silica) and carbon black are two important inorganic functional fillers. Although their names are similar, they differ significantly in structure, properties, preparation methods, and applications. In many industries, they not only demonstrate unique advantages but also complement each other.

Basic Concepts and Properties

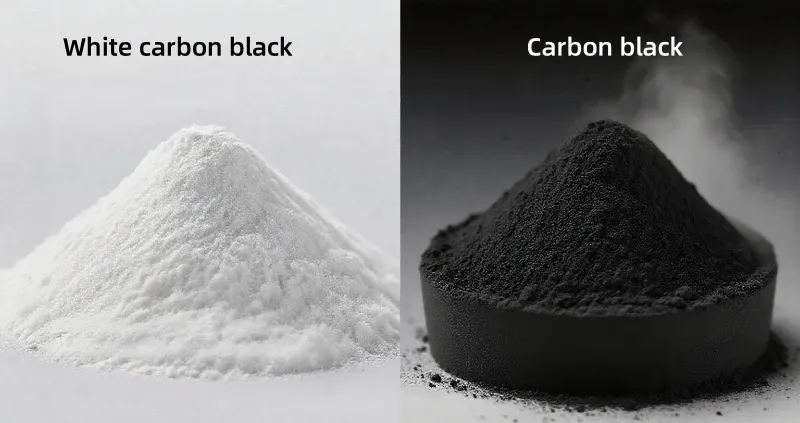

White Carbon Black (SiO₂·nH₂O)

- Nature: Amorphous silicon dioxide synthesized mainly by precipitation or fumed methods.

- Appearance: White powder with high specific surface area and porous structure.

- Key Properties: Large surface area, strong adsorption capacity, chemical stability, hydrophilic nature (or hydrophobic after surface modification).

Carbon Black (C)

- Nature: Amorphous carbon obtained by the incomplete combustion or thermal decomposition of hydrocarbons.

- Appearance: Black fine powder, usually in an aggregated state.

- Key Properties: Extremely small particle size, high structure, strong blackness, good electrical conductivity, excellent reinforcing performance.

Preparation Methods

White Carbon Black: Produced mainly by the precipitation method (reaction of sodium silicate with sulfuric or hydrochloric acid) and the fumed method (hydrolysis of silicon tetrachloride in a hydrogen–oxygen flame). The precipitation method has lower cost and higher output, while the fumed method produces purer and higher-performance products.

Carbon Black: Produced by furnace method (partial combustion of natural gas or heavy oil), channel method, and thermal decomposition. Among them, the furnace process dominates in production and applications.

Application Fields

Applications of White Carbon Black

- Rubber industry: As a reinforcing filler, especially in green tires, it reduces rolling resistance, improves wet grip, and lowers fuel consumption.

- Coatings and inks: Used as a matting agent and rheology controller, improving wear resistance and anti-settling performance.

- Plastics and adhesives: Enhances mechanical strength, barrier properties, and anti-aging performance.

- Pesticides, feed, toothpaste: Serves as a carrier, diluent, or abrasive.

Applications of Carbon Black

- Rubber industry: The most important reinforcing filler for tires, seals, hoses, etc., improving wear resistance and mechanical strength.

- Pigments: Widely used in inks, coatings, and plastics as a black pigment with excellent tinting strength and lightfastness.

- Conductive materials: Conductive carbon black is used in cables, lithium batteries, and electrode materials.

- Others: Applied as a catalyst carrier, UV stabilizer, and more.

Comparison Between White Carbon Black and Carbon Black

| Item | White Carbon Black | Carbon Black |

| Appearance | White powder | Black powder |

| Main Component | SiO₂·nH₂O | C |

| Particle Size | Nano-scale, aggregated | Nano-scale, aggregated |

| Features | High surface area, hydrophilic, reinforcing but non-conductive | Strong blackness, conductive, excellent reinforcing ability |

| Rubber Application | Improves rolling resistance and wet grip (green tires) | Enhances wear resistance, tear resistance, and strength |

| Typical Uses | Green tires, toothpaste, pesticide carrier | Traditional tires, conductive plastics, pigments |

Relationship and Development Trends

With the rise of green and low-carbon concepts, white carbon black has increasingly formed a complementary relationship with carbon black in the tire industry:

- Traditional tires rely heavily on carbon black for reinforcement but suffer from higher rolling resistance and energy consumption.

- New-generation “green tires” use large amounts of silica in combination with silane coupling agents, significantly improving low rolling resistance and wet grip performance.

- In conductive materials and deep-colored plastics, carbon black remains irreplaceable. However, in transparent materials, eco-friendly tires, and functional carriers, silica shows clear advantages.

Looking ahead, in industries such as rubber, plastics, coatings, energy, and environmental protection, white carbon black and carbon black will continue to develop in a differentiated, functionalized, and synergistic manner.

Epic Powder

Epic Powder, 20+ years of work experience in the ultrafine powder industry. Actively promote the future development of ultra-fine powder, focusing on crushing, grinding, classifying and modification process of ultra-fine powder. Contact us for a free consultation and customized solutions! Our expert team is dedicated to providing high-quality products and services to maximize the value of your powder processing. Epic Powder—Your Trusted Powder Processing Expert !