Exploring 10 Minerals Grinding Technology for Enhanced Processing Efficiency”

Mineral processing aims to remove impurities and improve product purity, while also reducing particle size to varying degrees. Currently, crushing, grinding, and classification technologies and equipment have reached a new level, meeting the needs of most raw materials in various industries, including non-metallic minerals, cement, ceramics, chemicals, coal powder, metallic minerals, tailings, and waste solid […]

What is the Production Process for Artificial Graphite Anode Materials?

The production of artificial graphite anode materials involves multiple key processes. These processes are closely linked and mutually influential, collectively determining the performance and quality of the final product. The following is a brief overview of the main processes: Serial Number Process Name Main Function 1 Raw Material Inspection Ensure that incoming materials meet quality […]

Why Is Aluminum Powder Used in the Production of Aerated Concrete Blocks?

Aerated concrete blocks, also known as Autoclaved Aerated Concrete (AAC), are lightweight building materials. They are made from siliceous materials such as fly ash or quartz sand, and calcareous materials like lime or cement. Aluminum powder serves as the foaming agent. The blocks are produced through batching, mixing, casting, pre-curing, cutting, and autoclaving. Their main […]

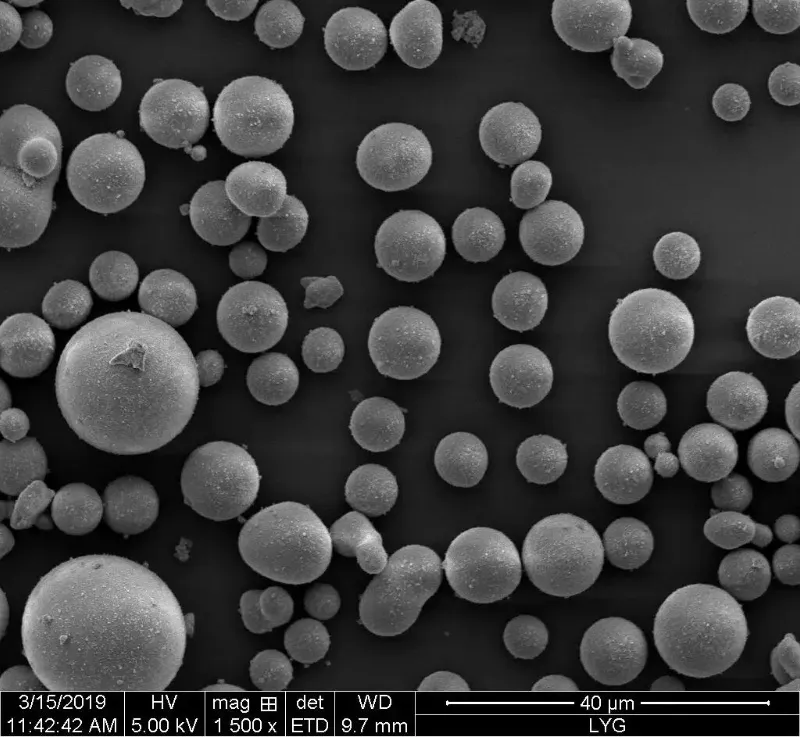

What Makes Spherical Powder Unique and How Are They Produced?

With the rapid development of modern industry and technology, the performance requirements for powder materials in different sectors have become increasingly stringent. In addition to low impurity content, fine particle size, and narrow particle size distribution, powders are also required to have specific particle morphologies. Spherical powder, due to their superior flowability and uniformity, are […]

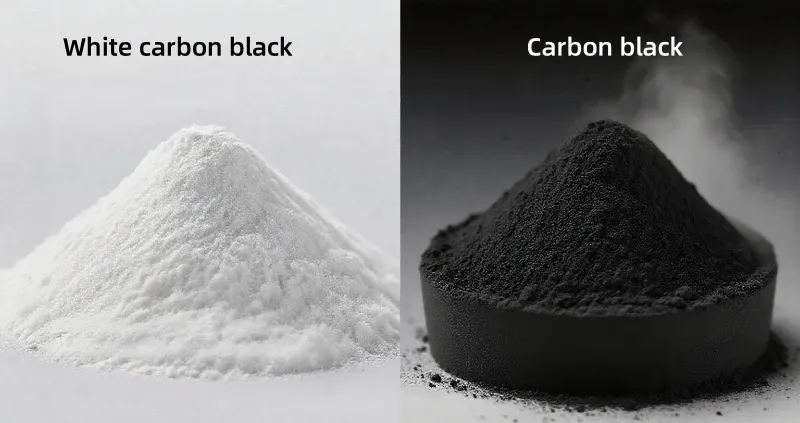

Comparison of White Carbon Black and Carbon Black

In the field of powder materials, white carbon black (precipitated silica) and carbon black are two important inorganic functional fillers. Although their names are similar, they differ significantly in structure, properties, preparation methods, and applications. In many industries, they not only demonstrate unique advantages but also complement each other. Basic Concepts and Properties White Carbon […]

Introduction to silver powder classification technology and commonly used equipment

The particle size range of spherical silver powder used in crystalline silicon solar front-side silver paste is 1.0–3.0 μm, while conventionally synthesized silver powder usually has a wide particle size distribution. Therefore, the prepared silver powder must undergo classification treatment to meet the requirements for silver powder used in crystalline silicon solar cell electrode silver […]

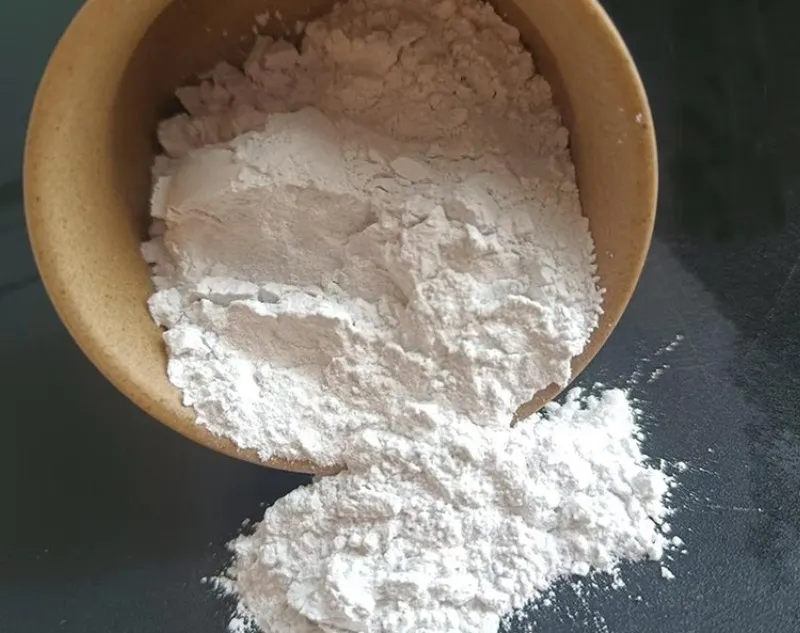

Influence of Surface-Modified Quartz Powder on Artificial Quartz Stone Performance

Artificial stone is one of today’s most important building and decorative materials. It can replace natural stone, high-end ceramics, wood, and metal decoration materials. It is a green, environmentally friendly building material. Among these, quartz stone is a key variety of artificial stone. Quartz powder plays a vital role as an inorganic, non-metallic functional filler […]

Polyetheretherketone (PEEK) — One of the Hottest Materials of the Year

In today’s era of rapid technological development, industries such as aerospace, humanoid robotics, and new energy vehicles are placing increasingly stringent demands on material performance. PEEK offers high strength, high modulus, and excellent stability under stress. It has become one of the most noteworthy materials of the year. Polyetheretherketone (PEEK) performs exceptionally well in humanoid […]

Grinding Machines for Ultrafine Graphite Powder

Graphite is an important non-metallic mineral. It has many properties: electrical conductivity, thermal conductivity, high-temperature resistance, thermal shock resistance, chemical stability, lubrication, and plasticity. Because of these features, it is widely used in metallurgy, machinery manufacturing, electrical, chemical, and nuclear industries. With the development of the graphite industry, the development of deep processing technologies and […]