Low Temperature Impact Mill- a New Type of Ultra-Fine Grinding Equipment

Ultra-fine grinding technology reduces particle size by overcoming internal cohesion through mechanical or fluid power. It achieves a particle size reduction to 10–25μm, increasing surface area and porosity. This technology is widely used in the pharmaceutical and food processing industries. It can be divided into dry and wet ultra-fine grinding, depending on the moisture content […]

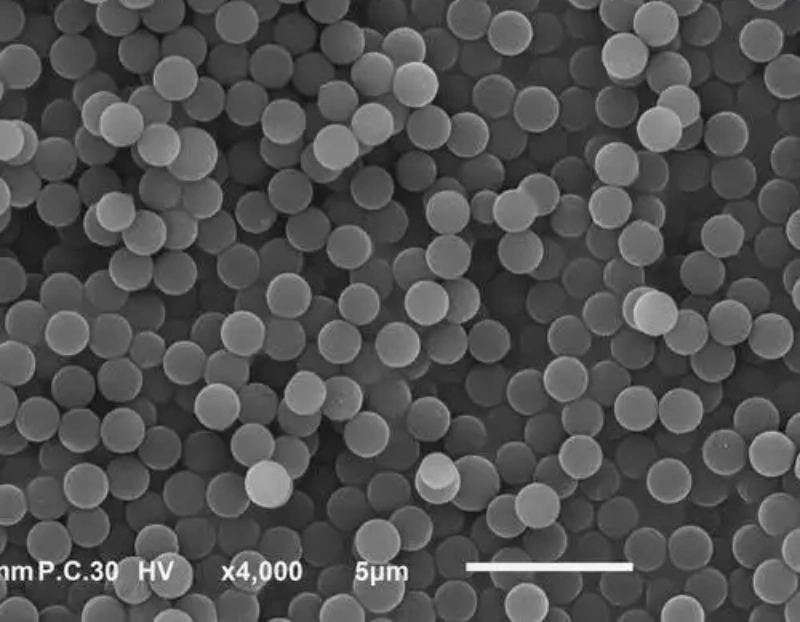

The Magical Microscopic World——PMMA Microspheres

PMMA microspheres are tiny spheres made of polymethyl methacrylate (PMMA). PMMA is a thermoplastic (also as known as acrylic or plexiglass) with high transparency, good processing performance, strong weather resistance and excellent chemical stability, and is widely used in many fields. Preparation Method of PMMA Microspheres Emulsion Polymerization Under the action of the emulsifier, the […]

Application of Air Jet Milling Technology in the Field of Ultrafine Powders

Ultrafine powder typically refers to powdered materials with a particle size of less than 10μm. It plays an important role in various industrial productions. With the continuous development of science and technology, many industries now require powder raw materials with smaller particle sizes, higher purity, and no impurities. They also demand tighter control over the […]

Welcome to Qingdao To Attend The 22nd AP-Plastics Rubber Exhibition

Qingdao EPIC Powder Machinery Co.,ltd. sincerely invites you to participate in the The The 22nd AP-Plastics Rubber Exhibition. 10-13 July 2025 , Qingdao Cosmopolitan Exposition. No. 3399, Sansha Road, West Coast New District, Qingdao City, Shandong Province.Booth No.Hall S3 C77 Epic Powder Epic Powder, 20+ years of work experience in the ultrafine powder industry. Actively promote […]

The Application of Silicon-Carbon Anode Materials in the Lightweight Design of Consumer Electronics.

In today’s consumer electronics market, there is an increasing demand from consumers for lightweight and long-lasting products. From smartphones to wearable devices, products that are both slim and portable with long battery life are highly favored. The emergence of silicon-carbon anode materials has brought new hope to meet this demand and is gradually becoming a […]

Do You Know the 8 Concepts of Bentonite?

Bentonite is an important natural mineral resource. It is widely used in many industrial fields such as petroleum drilling, casting, environmental protection, agriculture, and chemical processing. This is due to its unique swelling properties, adsorption capacity, and multifunctionality. The main component of bentonite is montmorillonite. However, bentonite can be classified into several types. These types […]

How do Surfactants Affect Powder Agglomeration?

Surfactants significantly affect the agglomeration behavior of powder. They change the interfacial properties, force balance, and medium environment of powder particles. The specific mechanism can be divided into five aspects: Adsorption Modification and Surface Energy Reduction Surfactants adsorb onto powder surfaces. This lowers surface energy and suppresses powder agglomeration. The mechanisms include: Hydrophobic Group Anchoring: […]

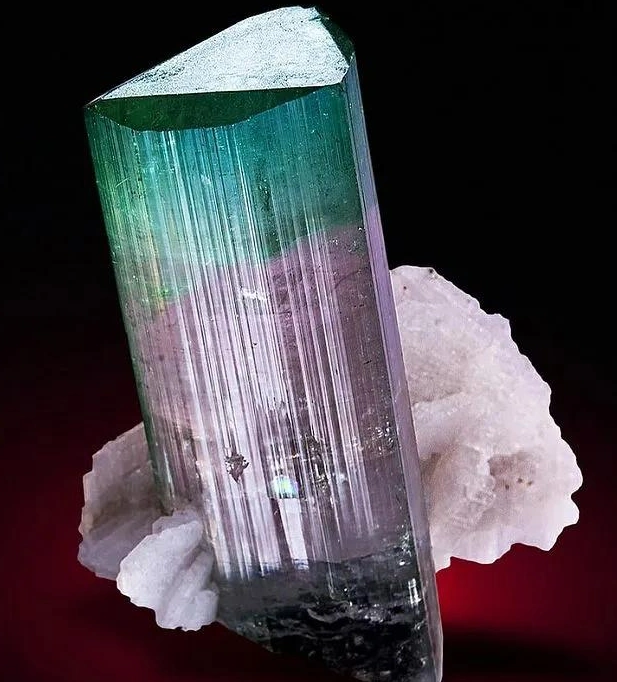

High Whiteness Negative Ion Powder Preparation Technology

Tourmaline is a silicate mineral with a complex ring structure made of sodium, magnesium, iron, aluminum, and lithium, and is characterized by boron. It has good thermoelectric and piezoelectric effects. It also releases negative ions, radiates far infrared rays, and possesses antibacterial and deodorizing functions. These properties are beneficial to both humans and the environment. […]

How to Choose the Right Quartz Sand for Different Industries ?

Quartz sand is an important basic non-metallic mineral resource, widely used in fields such as glass manufacturing, mechanical casting, electronics, metallurgy, refractory materials, chemicals, and ceramics. Customers often ask which products their quartz ore is suitable for and which industries it can be applied to. Based on the silica (SiO2) content, a preliminary judgment can […]