How Does Ultrafine Grinding Technology Enable Talc, the “Softest Mineral,” to Cross into High-end Manufacturing Fields?

Talc, a mineral often overlooked, ranks dead last on the Mohs hardness scale, yet its “softness” delivers remarkable “hardcore” strength. As the softest known mineral, talc plays important roles not only in daily life but also shines across multiple industries. However, its true potential is often unlocked through the process of producing ultrafine grinding talc, […]

What Are the Causes of Low Activity During Slag Powder Grinding and Their Solutions?

1. Causes of Low Activity of Slag Powder Many factors contribute to the low activity of slag powder. A high proportion of crystalline phases and a complete crystal structure are primary factors. Furthermore, a high content of acidic oxides like SiO2 and a low content of basic oxides like CaO further reduce activity. When analyzing […]

What Are the Preparation Processes of Ultrafine Aluminum Hydroxide Powder and Its Surface Modification Mechanisms?

Aluminum hydroxide (ATH) possesses multiple functions, including flame retardancy, smoke suppression, and filling. It does not produce secondary pollution and can generate synergistic flame-retardant effects with various substances. Therefore, it is widely used as a flame-retardant additive in composite materials and has become the most widely consumed environmentally friendly inorganic flame retardant. When aluminum hydroxide […]

Why is Ultrafine Grinding Becoming Essential for Modern Bentonite Applications?

Bentonite is widely acclaimed as the “Universal Clay,” with its core mineral constituent being Montmorillonite. This layered silicate, forged from volcanic ash over millions of years, spans two vastly different worlds: from $10-a-bag cat litter to high-precision chemical additives. This versatility is not merely a result of its natural chemistry, but rather a masterpiece of […]

Does Ultra-fine Pulverization of Sodium Carbonate Really Solve the Poor Rate Performance Problem of Sodium-ion Batteries?

Sodium-ion batteries (SIBs) have attracted significant attention in recent years due to abundant sodium resources, low cost, and advantages in low-temperature performance and safety. However, compared to mature lithium-ion batteries, SIBs still face a prominent shortcoming — poor rate capability. Rate capability refers to a battery’s ability to maintain capacity and enable fast charge/discharge at […]

How to Achieve Morphology Control of Powder Particles?

Morphology control of powder particles is one of the core technologies in advanced material preparation. It directly determines the packing density, flowability, sintering activity, and the final microstructure and performance of ceramic products. The objective of morphology control is to obtain particle shapes that are specific, uniform, and reproducible. The following sections detail the mainstream […]

Why Use Air Jet Mill for Centella Asiatica? Advantages Compared to Traditional Grinding Methods

Centella asiatica (also known as Gotu Kola) is an important medicinal and edible plant. Its key active compounds — primarily triterpenoids (such as asiaticoside, madecassoside, asiatic acid, and madecassic acid) along with flavonoids and polyphenols — are in high demand in modern pharmaceuticals, nutraceuticals, and cosmetics. These applications place strict requirements on the fineness, uniformity, […]

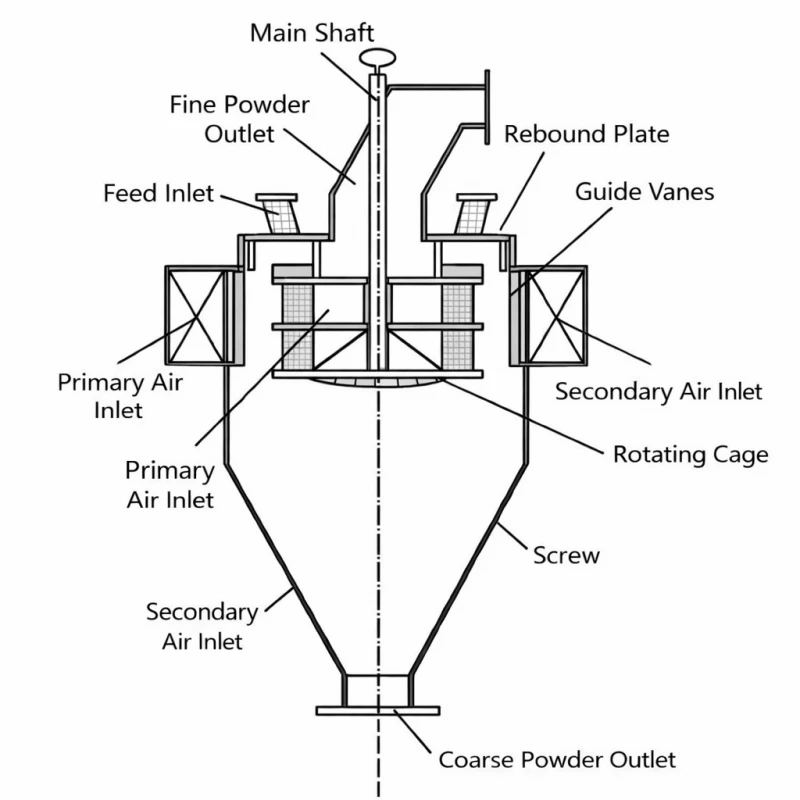

What Are The Working Principles, Advantages, and Challenges of a Turbo Air Classifier?

Particle classification refers to separating particles of the same material according to differences in physical properties such as particle size, shape, or density. In most cases, classification specifically means separating particles by size. The two core technical elements of classification are dispersion and separation. Dispersion requires that the material entering the classification chamber be as […]

How PEEK Becomes the Strategic Material Foundation for Mass-Produced Humanoid Robots?

Macro Background: Humanoid Robots Enter the “Lightweight Era” As humanoid robots enter their first year of mass production, the industry is facing unprecedented technological challenges and opportunities. Among them, the most prominent issue is the contradiction between battery endurance and effective payload. Traditional humanoid robot designs rely heavily on metallic materials such as aluminum alloys […]