In the production process of artificial graphite anodes, grinding is an essential front-end step. As the very first stage, it plays a crucial role in determining efficiency and product quality. Artificial graphite anode grinding equipment mainly includes roller mills, mechanical mills, and jet mills. Jet mills are mainly used for asphalt pulverization, roller mills are primarily applied in the calcined coke production line, while mechanical mills are widely used in the green coke production line.

Artificial Graphite Anode Grinding Process Flow

Roller Mill Process Flow: Feeding → Hammer Crusher (Coarse Crushing) → Roller Mill (Grinding) → Shaping (Spheroidization) → Classification

Mechanical Mill Process Flow: Feeding → Hammer Crusher (Coarse Crushing) → Rotary Kiln (Drying) → Mechanical Mill (Grinding) → Shaping (Spheroidization) → Classification

Hammer Crusher (Coarse Crushing)

- Purpose: Crush large raw materials into particles of about 10 mm, facilitating downstream drying and fine grinding processes, thereby improving production efficiency.

- Principle: The high-speed rotating hammer collides with the material. The hammer strikes the material, while particles collide with each other and against the liner. When the required particle size is reached, the material passes through the grate bars and is discharged. Otherwise, the material is repeatedly impacted until the target size is achieved.

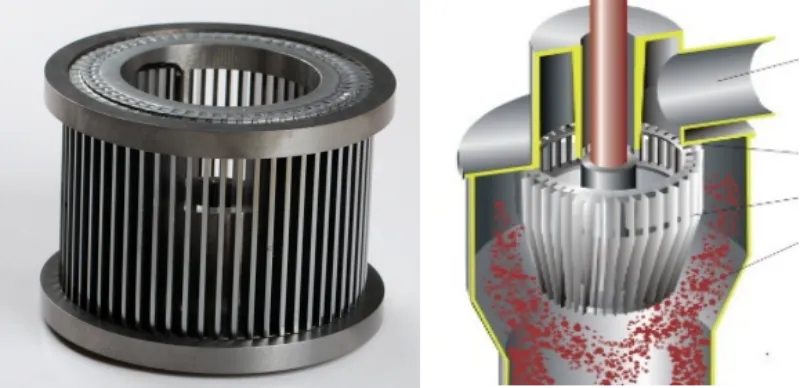

Roller Mill (Grinding)

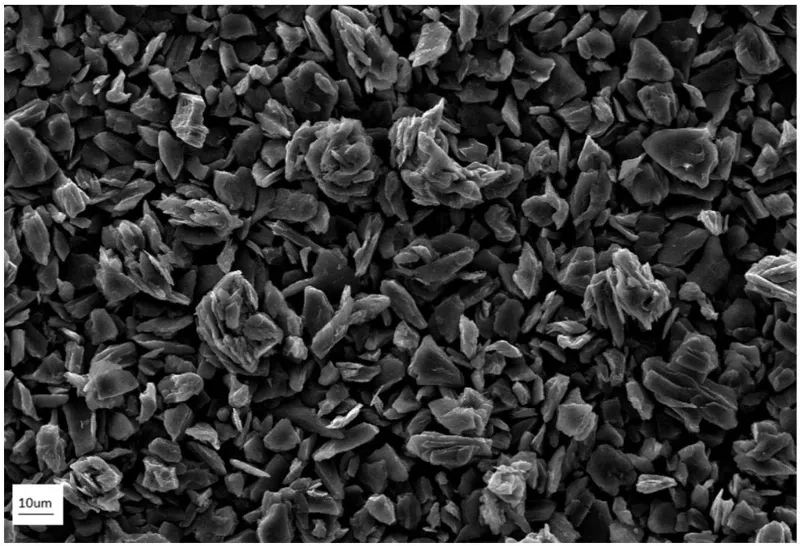

- Purpose: To ultrafine grind hard calcined coke after coarse crushing, achieving micron-level particle size control.

- Principle: The roller mill is an internally classified high-pressure ultrafine grinding system that simultaneously performs fine grinding and powder classification. Driven by the main shaft, the grinding wheel system rotates, generating powerful centrifugal force. Raw material enters the grinding zone between the rollers and the grinding ring, where it is crushed under intense pressure. The pulverized powder is carried upward by negative pressure airflow into the classifier chamber. Qualified fine powder passes through the classifier wheel into the collection system, while coarse particles fall back for regrinding.

Mechanical Mill (Grinding)

- Principle: Materials in the gap between stator and rotor undergo shearing and rebound into the grinding chamber, where they collide repeatedly with high-speed moving particles. The stator teeth and rotor hammers create a strong turbulent field, producing alternating stresses that pulverize the material.

- Purpose: To ultrafine grind the material after coarse crushing, ensuring micron-level particle size control.

- Mechanism: Multiple collisions provide energy greater than the breaking energy required by the particles, resulting in effective grinding.

Shaping Machine (Spheroidization)

Purpose: To spheroidize the particles, smooth sharp edges, and improve morphology. This enhances tap density and material packing performance.

Classifier Wheel (Powder Classification)

Powders are carried by airflow upward into the classifier chamber. During the ascent, secondary airflow separates entrained fine particles from coarse ones. At the high-speed rotating classifier wheel, powders are subjected to both centrifugal and centripetal forces.

- Coarse particles: Centrifugal force exceeds centripetal force, so they are rejected to the chamber wall and returned for further grinding.

- Fine particles: Centripetal force dominates, allowing them to pass through the classifier wheel gaps, exit with the airflow, and be collected downstream.

Epic Powder

Epic Powder specializes in advanced grinding equipment and process solutions for artificial graphite anodes. With more than 20 years of expertise in ultrafine grinding, classification, and shaping, we deliver tailored systems that ensure stable micron-level control, high efficiency, and consistent product quality. Whether roller mills, mechanical mills, or jet mills, our engineered solutions help customers maximize performance in battery materials and beyond.