Lithium-ion batteries are core energy storage technology for modern electronics and electric vehicles. Performance optimization has always been a focus. In battery design, the particle size of graphite negative electrode is typically much larger than that of positive materials (e.g., lithium iron phosphate, ternary materials, lithium cobalt oxide). This particle size difference results from factors such as material properties, electrochemical needs, manufacturing processes, and performance optimization goals. This article explores the reasons for this size difference and summarizes its effects on battery performance.

Differences in Material Properties and Electrochemical Requirements

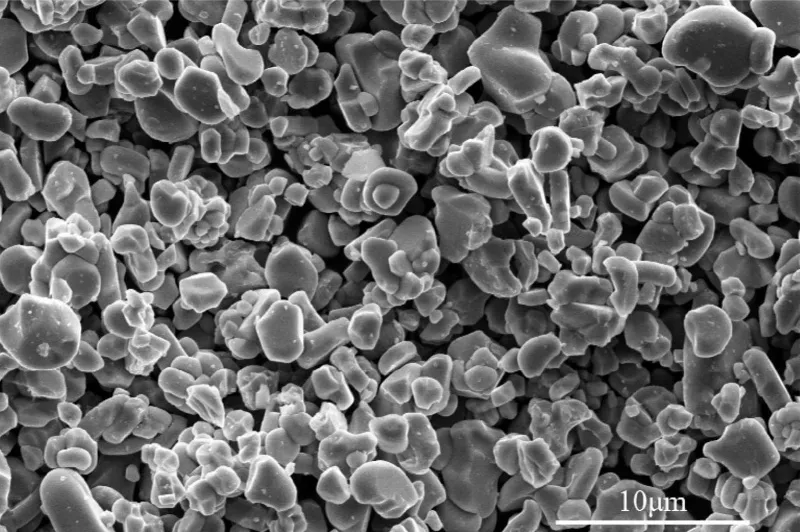

Characteristics of Positive Materials and Particle Size Requirements

Cathode materials include lithium cobalt oxide (LiCoO₂), lithium iron phosphate (LiFePO₄), ternary materials (e.g., LiNiₓCoᵧMn₁₋ₓ₋ᵧO₂). These materials have smaller particle sizes for the following reasons:

- Poor conductivity: Materials like lithium iron phosphate have low conductivity. Smaller particles shorten lithium ion diffusion paths and improve rate performance.

- Optimization of specific surface area: Smaller particles increase surface area, helping lithium ion insertion and extraction. However, they may agglomerate. Lithium iron phosphate tends to agglomerate, so particle size must be controlled.

- Small volume change: The volume change during charge/discharge in cathode materials is small (about 6.5% for lithium iron phosphate). This allows smaller particles to optimize performance.

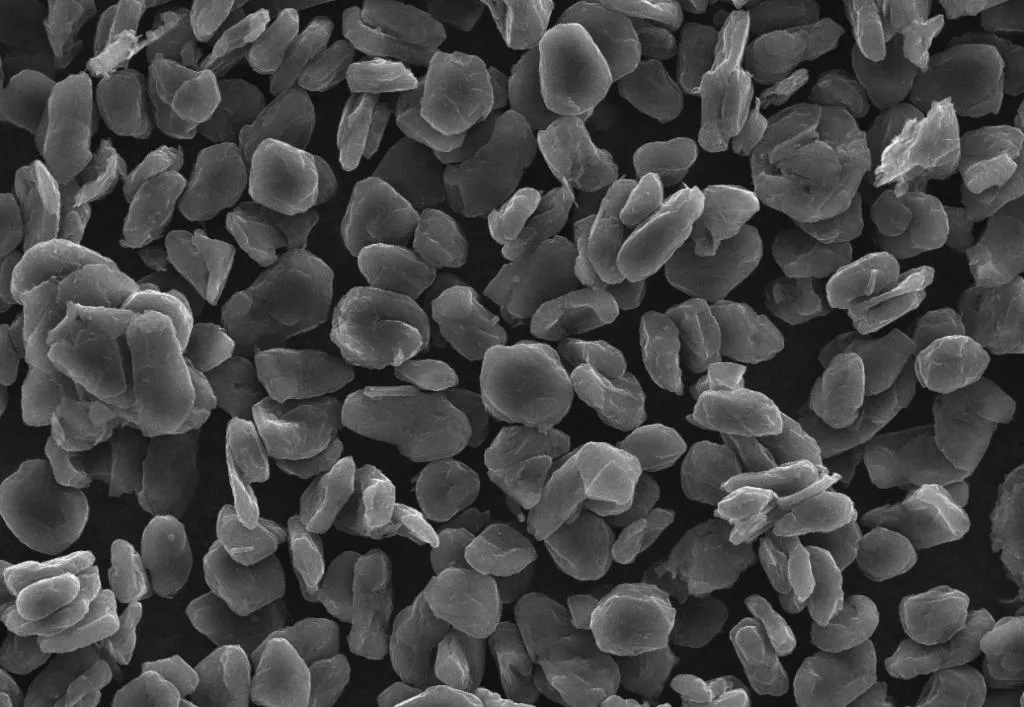

Characteristics of Graphite Negative Electrode and Particle Size Requirements

Graphite negative electrode materials (including natural, synthetic graphite, and silicon-based anodes) typically have larger particle sizes. The reasons are:

- Excellent conductivity: Graphite has good conductivity. Larger particles reduce side reactions with the electrolyte and minimize first-cycle irreversible capacity loss.

- Buffering volume changes: Graphite expands 10-15% during charge/discharge, while silicon-based anodes expand up to 300%. Larger particles buffer stress, reduce cracking, and extend cycle life.

- Structural stability: The layered structure of graphite is more stable in larger particles, preventing fragmentation due to expansion.

Volume Changes and Structural Stability

Volume Changes During Charge and Discharge

- Negative electrode volume change: Graphite expands by 10-15%, and silicon by 300%. Larger particles buffer this stress, reducing cracking and extending cycle life.

- Positive electrode volume change: Cathode materials (like lithium iron phosphate) have a small volume change (about 6.5%). Smaller particles optimize performance.

Structural Stability Requirements

- Anode: Larger particles reduce interface stress, preventing particle cracking or SEI membrane rupture.

- Cathode: Smaller particles increase structural density, improving lithium ion diffusion efficiency.

Manufacturing Processes and Slurry Stability

Slurry Preparation and Coating Process

Cathode slurry:

- Requires high dispersibility for uniform coating. Smaller particles are easier to mix evenly. Particle size (e.g., 5-15μm) must be controlled to prevent agglomeration.

- Challenge: Smaller particles have low slurry viscosity and tend to level during coating. Thickeners (e.g., CMC) prevent settling.

Anode slurry:

- Needs larger particles (10-20μm) to reduce settling and improve slurry stability. This avoids scratches or breaks during coating.

- Advantage: A wide particle size distribution (e.g., 10-20μm) helps smaller particles fill gaps between larger ones, improving electrode density and volumetric energy density.

Industry Standards and Application Scenarios

Battery types have different particle size requirements:

- Lithium Cobalt Oxide Battery: Cathode 5-15μm, Anode 10-20μm.

- Lithium Iron Phosphate Battery: Cathode nanoscale (0.1-1μm), Anode 10-20μm (nano-sized for enhanced conductivity).

- Ternary Battery: Cathode 5-15μm, Anode 10-20μm (balancing energy density and safety).

Comprehensive Summary of Reasons

Electrochemical Performance Optimization

- Cathode: Smaller particles enhance rate performance and capacity.

- Anode: Larger particles reduce side reactions and improve first-cycle efficiency.

Structural Stability

- Anode: Larger particles reduce stress during charge/discharge, enhancing stability.

- Cathode: Smaller particles improve lithium ion diffusion efficiency and optimize electrochemical performance.

Manufacturing Process Adaptation

- Cathode slurry: Requires high dispersibility, so smaller particles work best.

- Anode slurry: Needs high stability, making larger particles more suitable.

Industry Standards Verification

Industry standards (e.g., lithium cobalt oxide, ternary batteries) specify particle sizes to balance performance and safety.

Epic Powder

The larger particle size of graphite negative electrode compared to cathode materials in lithium-ion batteries is the result of multiple factors. These include material properties (conductivity, volume changes), electrochemical needs (rate performance, cycle life), manufacturing processes (slurry stability, coating uniformity), and performance optimization goals. With Epic Powder’s advanced grinding and classification technologies, these material characteristics can be precisely controlled to enhance battery performance. Epic Powder’s customized solutions for particle size optimization ensure that both anode and cathode materials achieve optimal efficiency and stability. This design, coupled with Epic Powder’s cutting-edge equipment, is key to optimizing energy density, cycle stability, and safety, positioning it as a crucial factor in advancing lithium-ion battery technology.