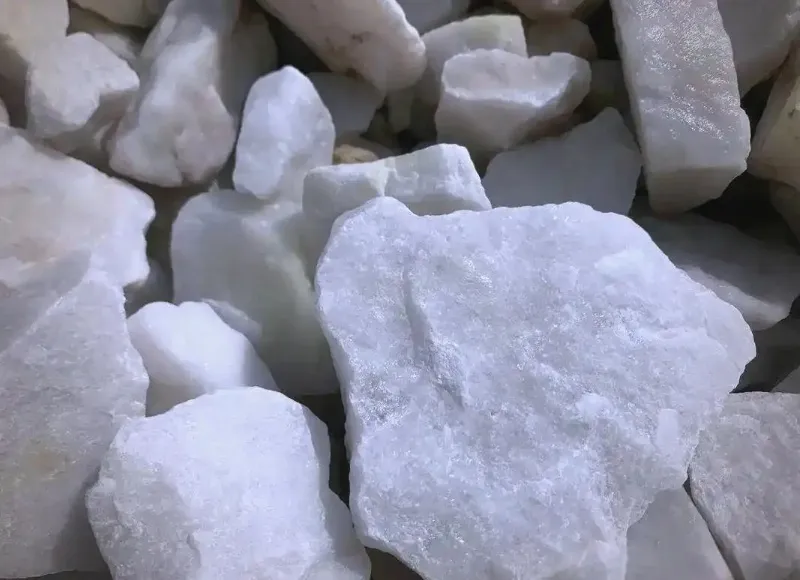

High Purity Quartz (HPQ) is a quartz raw material with extremely high SiO₂ content and very low impurities. The required SiO₂ content usually exceeds 99.99%. Thanks to its excellent thermal stability, very low thermal expansion coefficient, and extremely high purity, HPQ is widely used in semiconductors, photovoltaics, new displays, optical communications, and high-end quartz glass products. It is often called the “gold of quartz materials.”

From mobile phone screens to satellite lenses, and from new energy vehicles to spacecraft, HPQ plays a vital role. This mineral, with a purity of more than 99.5%, has three “superpowers”:

- High heat resistance: Its melting point is nearly 1750°C, which is 500°C higher than volcanic lava.

- Super insulation: A thickness of 1 cm can withstand 250,000 volts of high voltage.

- Excellent transparency: Its transmittance exceeds 99%.

However, the production of HPQ is much more than mining. It requires multiple complex processes such as crushing, grinding, classification, and purification. Among them, grinding is the most critical. Proper grinding equipment not only determines the particle size distribution of quartz powder but also directly affects purification results and material performance.

Importance of Grinding in High Purity Quartz Production

- Particle size control: HPQ requires strict particle size. It is usually controlled at the micron or even submicron level. The more uniform the particle size, the more stable the performance in optical and electronic applications.

- Impurity removal: Reducing metal contamination during mechanical grinding is a core challenge. It requires special wear-resistant materials and closed systems.

- Surface activation: Ultrafine grinding increases the specific surface area. This creates favorable conditions for subsequent acid leaching and flotation purification.

For example, jet milling technology has unique advantages in HPQ processing. It uses high-speed airflow to accelerate particles, causing them to collide and grind against each other. This method avoids direct contact between mechanical parts and the material. As a result, it greatly reduces impurities, making it ideal for HPQ production.

Air classifiers are also indispensable in HPQ processing. By precisely controlling airflow speed and direction, they separate quartz particles by size. Oversized particles and excessive fines are removed. This improves overall quality and consistency.

Core Application Scenarios of High Purity Quartz

Semiconductor manufacturing

- 12-inch wafers require 4N-grade quartz crucibles.

- Lithography lenses demand quartz glass with internal bubbles less than 5 μm.

- In 2024, YMTC production lines consumed more than 20 tons of HPQ products per month.

New energy sector

- Quartz crucible lifetime determines silicon rod growth efficiency in photovoltaic furnaces.

- Every 1 GW of solar capacity requires about 300 sets of quartz components.

- Quartz fibers are used as reinforcement for hydrogen storage tanks.

Military and aerospace

- Quartz fiber composites reduce missile nose cone weight by 30%.

- Satellite quartz gyroscopes achieve precision of 0.001°/h.

- Deep-sea detector quartz windows withstand 100 MPa water pressure.

Epic Powder Solutions

With more than 20 years of experience in ultrafine powder processing, Epic Powder has developed efficient and low-contamination grinding and classification systems for HPQ:

- Ball mill and classification line: Suitable for mass production of ultrafine quartz powder. Ceramic liners and high-purity media minimize iron contamination.

- Jet mill: Uses high-speed airflow and particle collisions for grinding. It avoids metal wear contamination.

- Air classifier Mill: Precisely controls particle size distribution, from several microns to hundreds of microns.

- Surface modification system: Coats or modifies quartz powder, improving its compatibility and dispersion in resins and silicone rubber.

The production of HPQ is not only a challenge in material science. It is also a comprehensive test of equipment design and process control. With advanced grinding systems and rich engineering experience, Epic Powder provides efficient, eco-friendly, and reliable solutions. These innovations support the entire HPQ industry chain and help this strategic material reach broader applications.