Why Choose Biomass as a Precursor?

The shift toward Biomass-Derived Porous Carbon represents a critical evolution in materials science, moving away from non-renewable fossil sources like coal and pitch. By leveraging renewable organic matter, manufacturers achieve a dual advantage: superior electrochemical performance and a significantly reduced carbon footprint. At EPIC Powder Machinery, we provide the precision milling solutions necessary to transform these raw organic inputs into high-performance carbon powders.

Raw Material Diversity

Nature provides an inexhaustible supply of precursors. We see successful industrial applications utilizing a vast array of agricultural by-products, including coconut shells, rice husks, sawdust, and spent coffee grounds.

This diversity requires versatile processing equipment. Unlike uniform synthetic polymers, biomass varies significantly in density, moisture, and fiber content. Our Air Classifier Mills and Impact Mills are engineered to handle these variations, ensuring consistent feedstocks regardless of the raw material source.

- Hard Shells (Coconut/Walnut): Require high-impact forces to fracture dense lignin structures.

- Fibrous Stalks (Straw/Hemp): Demand shearing action to separate fibers efficiently.

- Soft Residues (Coffee Grounds): Need precise airflow control to prevent agglomeration.

Cost Efficiency through Waste Valorization

The economic argument for biomass carbon is undeniable. By adopting a waste valorization strategy—turning agricultural waste into value—producers eliminate the high procurement costs associated with petroleum coke or synthetic resins.

However, raw material savings are only half the equation. Processing efficiency determines the final margin. EPIC’s milling systems are designed for low specific energy consumption, ensuring that the low cost of the raw material is not negated by high electricity bills during the grinding phase.

| Cost Factor | Traditional Carbon Source | Biomass Precursor | EPIC Advantage |

|---|---|---|---|

| Raw Material | High (Coal/Pitch) | Low/Negligible (Waste) | N/A |

| Processing Energy | Standard | Standard | Optimized (Low kWh/ton) |

| Scalability | Linear | High | Industrial Scale-Up |

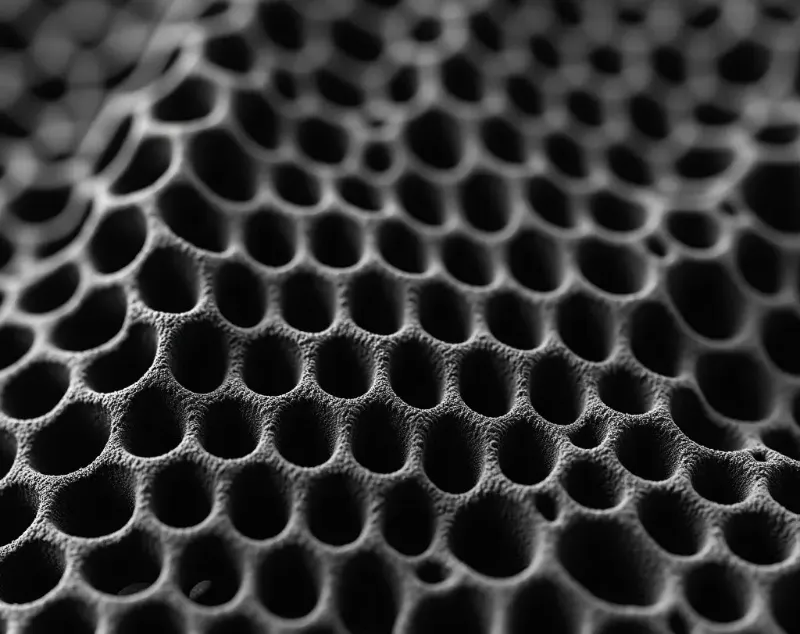

Inherent Pore Structures

The most distinct technical advantage of biomass is its natural cellular or fibrous microstructure. These biological architectures provide a pre-existing network of channels that facilitate ion transport and adsorption.

Preserving this structure during size reduction is critical. Aggressive, unrefined grinding can collapse these pores, reducing the material’s specific surface area. EPIC’s Fluidized Bed Jet Mills utilize particle-to-particle collision rather than mechanical impact. This method gently reduces particle size to the ultra-fine range (D50: 1-45μm) while maintaining the integrity of the inherent pore structures, reducing the complexity and cost of downstream activation processes.

Key Production Processes

Pre-treatment: Cleaning, drying, and milling of raw biomass

The journey from waste to high-value material begins with preparation. Raw biomass is often bulky and inconsistent, containing moisture and impurities that hinder processing. We start by thoroughly cleaning and drying the feedstock to ensure a stable base. Following this, precise size reduction is critical. Using efficient grinding equipment, such as our Pin Mill MJP, allows us to pulverize fibrous materials like coconut shells or rice husks into a uniform powder. This mechanical processing ensures consistent heat transfer and reaction rates in subsequent steps.

Carbonization: The pyrolysis process and its role in forming the carbon skeleton

Once the biomass is milled to the correct size, it undergoes carbonization. This involves heating the precursor in an inert atmosphere (typically nitrogen) to temperatures between 400°C and 800°C. This pyrolysis process drives off volatile organic components, leaving behind a stable, carbon-rich char. This step is fundamental as it constructs the initial carbon skeleton that defines the material’s structural integrity.

Activation Methods

To transform the carbonized char into Biomass-Derived Porous Carbon with high utility, we must develop its internal pore structure. This is achieved through activation.

Physical Activation: Utilizing steam or CO2

Physical activation is a clean, one-step or two-step process where the carbonized material is exposed to oxidizing gases like steam or carbon dioxide ($CO_2$) at high temperatures (800°C–1000°C). This controlled gasification burns off specific carbon atoms, clearing out the pores and creating a developed microporous structure without introducing foreign chemical agents.

Chemical Activation: Using agents like KOH, ZnCl2, or H3PO4

For applications demanding an ultra-high specific surface area, chemical activation is the preferred route. We impregnate the precursor with chemical agents such as potassium hydroxide ($KOH$), zinc chloride ($ZnCl_2$), or phosphoric acid ($H_3PO_4$). These agents dehydrate the biomass and inhibit the formation of tar, creating a rigid, highly porous network even at lower temperatures.

Washing & Purification: Removing ash content and residual activating agents

The final stage is purification. To ensure the material meets the strict standards required for energy storage or filtration, we must remove any remaining chemical agents and inorganic ash. This typically involves acid washing and extensive rinsing with water. Achieving high purity is essential, particularly when the material is intended to perform alongside or replace standard conductive additives like carbon black in battery anodes.

Core Performance Benefits

When we evaluate Biomass-Derived Porous Carbon against traditional coal-based or synthetic alternatives, the performance metrics are impressive. For industries ranging from energy storage to environmental protection, these materials offer a Low-Cost and Eco-Friendly solution without sacrificing technical capability. Here is why this material stands out.

Ultra-High Specific Surface Area (SSA) of Biomass-Derived Porous Carbon

The primary advantage of biomass carbon is its massive surface area. Through proper activation, we can achieve SSAs exceeding 2000 m2/g. This provides maximum active sites for adsorption or chemical reactions.

- High Adsorption Capacity: Ideal for filtration and gas storage.

- Enhanced Reactivity: More surface contact improves catalytic performance.

- Material Efficiency: Less material is required to achieve the same result compared to lower-grade carbons.

Tunable Pore Size Distribution

Biomass naturally possesses a hierarchical structure. By controlling the milling and activation process, we preserve a synergy between micropores, mesopores, and macropores. This hierarchical pore structure is critical for ion transport in batteries and supercapacitors.

Pore Functionality Breakdown:

| Pore Type | Size Range | Primary Function |

|---|---|---|

| Micropores | < 2 nm | High surface area for charge storage/adsorption. |

| Mesopores | 2–50 nm | Low-resistance pathways for ion transport. |

| Macropores | > 50 nm | Ion buffering reservoirs to shorten diffusion distances. |

Electrical Conductivity & Stability

For electronic applications, stability is non-negotiable. Biomass-derived carbon, particularly hard carbon, exhibits excellent structural stability and conductivity after high-temperature treatment. This makes it a prime candidate for next-generation battery anodes. We have seen significant success in this area, specifically where jet mill technology enables ultrafine hard carbon anode materials to meet strict conductivity standards.

Natural Heteroatom Doping

One of the unique “free” benefits of using biomass is the presence of natural heteroatoms like nitrogen (N), phosphorus (P), and sulfur (S). Unlike synthetic carbon which requires expensive post-treatment to dope, biomass retains these elements within the carbon matrix.

- Pseudocapacitance: Heteroatoms contribute to additional energy storage mechanisms.

- Wettability: Improves the interaction between the electrode surface and electrolytes.

- Cost Reduction: Eliminates the need for external doping agents during manufacturing.

To achieve these performance metrics consistently, precise particle size control is required during the R&D phase. Our laboratory mills are frequently used to test and refine these properties before scaling up to industrial production.

Key Application Areas

Energy Storage: Electrode materials for supercapacitors, Li-ion, and Na-ion battery anodes.

In the energy sector, biomass-derived porous carbon is rapidly becoming a preferred material for next-generation energy storage devices. We see immense demand for this sustainable alternative in the production of supercapacitors and anodes for Lithium-ion (Li-ion) and Sodium-ion (Na-ion) batteries. The critical factor for success in these applications is achieving a precise particle size distribution to ensure high conductivity and structural stability. Our experience with specific applications, such as the [Korean laboratory porous carbon jet mill optimization project](https://www.epicmilling.com/portfolios/korean-laboratory-porous-carbon-jet-mill-optimization-project/), demonstrates how controlling the milling process directly enhances the electrochemical performance of the final electrode material.

Environmental Remediation: Heavy metal adsorption in wastewater, organic pollutant removal, and gas purification (CO2 capture).

Beyond energy, this eco-friendly material is a powerhouse for environmental cleanup. Its ultra-high specific surface area makes it highly effective at adsorbing heavy metals from industrial wastewater and removing complex organic pollutants. We also see significant growth in gas purification applications, particularly for carbon capture (CO2). To maximize adsorption efficiency, the carbon feedstock must be processed into a specific fineness without collapsing its internal pore structure. Utilizing a specialized [ultra-fine grinder](https://www.epicmilling.com/tag/ultra-fine-grinder/) ensures the material retains its high reactivity while achieving the necessary particle size for filtration systems.

Catalyst Support: Replacing expensive synthetic supports in industrial chemical reactions.

Industrial chemistry often relies on costly synthetic supports for catalytic reactions. Biomass carbon offers a low-cost and eco-friendly material alternative that does not compromise on performance. Its natural stability and hierarchical porous architecture allow it to effectively anchor active catalytic species. By switching to biomass-derived supports, manufacturers can significantly reduce operational costs while maintaining high catalytic activity in large-scale chemical processes.

of Advantages in Application:

- Cost Reduction: Replaces expensive graphite or synthetic polymers.

- Sustainability: Utilizes renewable waste streams.

- Performance: High surface area improves adsorption and charge storage.

The Results of 2-3 Practices

We have seen firsthand how the right processing equipment transforms raw biomass carbon into high-value functional materials. Our engineering teams have tackled specific challenges in this field, delivering solutions that balance structural integrity with production efficiency.

- High-Efficiency Dispersion for Electronics:

In a recent collaboration, we engineered a porous carbon pin mill dispersion solution for a client in South Korea. The challenge was to break up agglomerated carbon particles without crushing the delicate internal pore structure. By utilizing our specialized pin mill technology, we achieved a uniform dispersion that maintained the material’s high specific surface area, ensuring optimal performance in conductive applications. - Contamination-Free Anode Material Processing:

For battery applications, purity is non-negotiable. We frequently implement Fluidized Bed Jet Mills lined with wear-resistant ceramics to process biomass-derived hard carbon. This setup guarantees zero metallic contamination during the ultra-fine grinding process. The result is a highly pure powder with a narrow particle size distribution (D50: 3–10 μm), which is essential for the stability and safety of Lithium-ion batteries. - Scalable Activated Carbon Production:

When cost reduction is the priority for large-scale filtration media, our Air Classifier Mills prove to be the workhorse. These systems allow for the continuous processing of tons of activated carbon per hour. By integrating precise classification, we help manufacturers achieve the exact fineness required for water or air filtration products while keeping energy consumption significantly lower than traditional ball milling circuits.

“Thanks for reading. I hope my article helps. Please leave a comment down below. You may also contact Zelda online customer representative for any further inquiries.”

— Posted by Emily Chen