In the lithium-ion battery industry, the ultra-fine grinding and classification of cathode and anode materials are key processes that directly determine material performance. Whether it is high-nickel cathode (NCM/NCA), lithium iron phosphate (LFP), artificial graphite, soft carbon, or hard carbon, powder quality strongly affects battery energy density, rate capability, and cycle life. As battery performance continues to advance, pulverizing equipment faces unprecedented challenges: high purity, high reactivity, high hardness, and high safety requirements. Traditional metal-lined mills can no longer meet these demands. This is why ceramic-lined pulverizing equipment has become the mainstream solution for new energy material producers.

This article explains the core value of ceramic liners from five perspectives: corrosion resistance, purity, safety, process stability, and equipment longevity.

Extreme Corrosion and Wear Resistance: The Best Choice for Highly Active and Hard Materials

Cathode and anode materials usually exhibit high hardness and strong reactivity. High-nickel precursors, lithium salts, and certain carbon materials can severely corrode or abrade equipment surfaces.

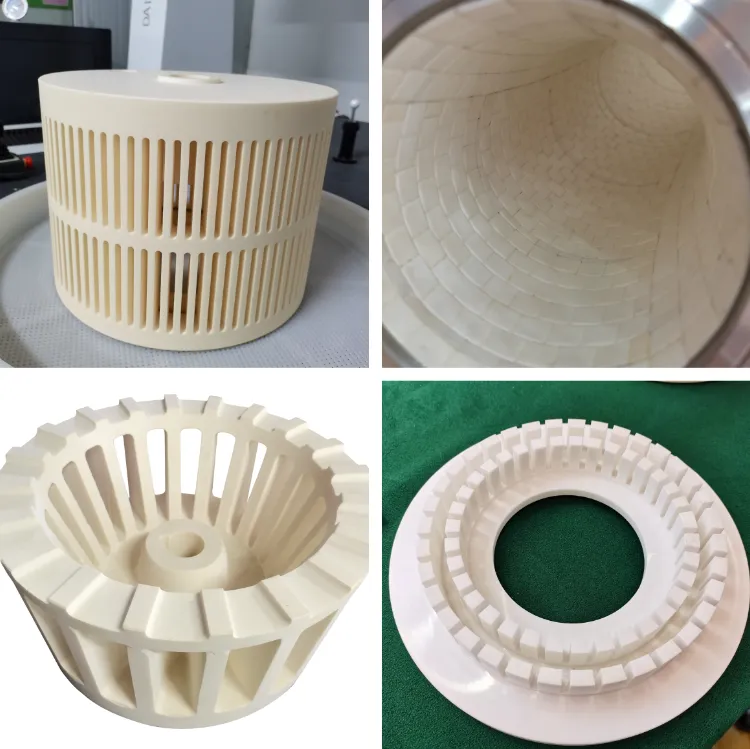

- Ceramic materials (e.g., alumina, zirconia) offer outstanding wear resistance and corrosion resistance.

- Even during long-term processing of highly corrosive or abrasive powders, they show minimal wear.

- This prevents metal debris from entering the material stream.

Ceramic linings significantly extend equipment lifespan while maintaining structural stability.

Chemical Inertness Ensures Ultra-High Purity: The Foundation for High Energy Density Batteries

Cathode and anode materials are extremely sensitive to metal contamination. Even trace amounts of metal ions (Fe, Cu, Cr, Ni, etc.) can cause:

- Reduced electrochemical performance

- Increased side reactions

- Faster capacity fading

- Severe safety risks

Ceramic liners are highly chemically inert, and even under high-speed impact or friction, they release no metal ions. This fundamentally ensures powder purity — essential for achieving high energy density and stable battery cycling.

Eliminating Metal Foreign Particles: Preventing Short-Circuit Risks Inside the Battery

Among all battery failure causes, “internal short circuits caused by metal particles” are among the most dangerous.

Conventional metal-lined mills inevitably wear over time, generating:

- Iron, copper, chromium, or other metallic micro-particles

- Tiny metal fragments that contaminate cathode and anode powders

These particles can pierce the separator, trigger internal short circuits, and lead to thermal runaway or explosions.

Ceramic linings eliminate metal particle generation at the source, providing maximum safety for battery materials.

Smooth and Dense Surface: Significantly Reduces Wall Adhesion and Blockages

Many battery materials have high viscosity or are prone to agglomeration (e.g., LFP, graphite, silicon–carbon materials). The rough interior surface of metal liners easily causes:

- Powder adhesion

- Pipeline blockages

- Material stagnation, degradation, or contamination

- Frequent shutdowns for cleaning

Ceramic liners offer excellent surface smoothness, providing:

- Reduced powder sticking

- Improved powder flow behavior

- Higher production continuity and stable throughput

This is crucial for high-capacity, low-energy-consumption battery material plants.

Excellent Thermal Stability: Ensuring Long-Term Reliability and Extended Equipment Life

Pulverizing processes often involve high temperatures or fluctuations — especially during ultra-fine grinding, inert gas milling, or thermal drying operations.

Ceramics offer:

- Very low thermal expansion

- Exceptional thermal stability

- Resistance to deformation or cracking under temperature swings

This enhances equipment reliability and significantly reduces maintenance requirements, achieving a lower total cost of ownership (TCO).

Conclusion: Ceramic-Lined Pulverizing Equipment Has Become the Industry Standard for New Energy Materials

As the new energy industry rapidly evolves, pulverizing equipment is no longer a “supporting tool,” but a core technology that directly affects material quality and battery performance.

Ceramic-lined equipment, with its:

- Extreme wear resistance

- Chemical inertness

- Guaranteed high purity

- Zero metal contamination

- High operational stability and long service life

has become indispensable in cathode and anode material production. For companies building or upgrading powder processing lines, choosing ceramic-lined equipment is not only a technological upgrade but also a strategic move to secure product quality, safety, and competitiveness.

“Thanks for reading. I hope my article helps. Please leave a comment down below. You may also contact Zelda online customer representative for any further inquiries.”

— Posted by Emily Chen