After mechanical crushing, ultrafine Silicon powder has irregular particle shapes. Due to its small size and high surface energy, the particles easily agglomerate. This results in poor dispersion, which is unfavorable for ceramic forming and sintering. Therefore, silicon carbide surface modification is required. It improves the dispersion and stability of the powder. This also enhances the forming performance of the powder. There are many surface modification methods. Among them, surface coating modification and surface chemical modification are widely applied.

Surface Coating Modification

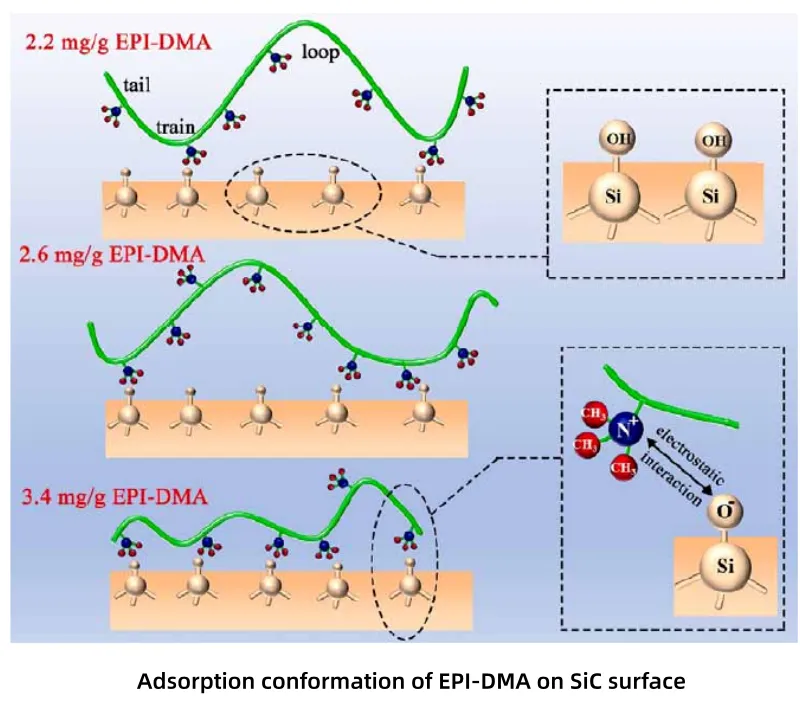

Surface coating modification involves mixing ultrafine powders with a modifier in a specific ratio in water or an organic medium. After magnetic stirring or ball mill for a specified period of time, the modifier adheres to the particle surface through interactions such as hydrogen bonding or electrostatic attraction, forming a single or multiple layer coating.

This coating enhances electrostatic repulsion or steric repulsion between particles, thereby reducing powder agglomeration. It also improves the dispersion stability of ceramic powders in water or organic media.

The key difference between surface coating modification and chemical surface modification lies in whether the modifier undergoes chemical adsorption or chemical reaction with the powder surface. Surface coating modification is applicable to almost all inorganic powders. Common modifiers used in surface coating modification include inorganic substances, surfactants, and dispersants.

Surfactants

Surfactants are amphiphilic substances whose molecules consist of a nonpolar, hydrophobic portion and a polar, hydrophilic portion. As a result, surfactants possess numerous properties, such as excellent surface activity, wettability, surface tension reduction, and adsorption at interfaces. These properties make them effective dispersants for ultrafine powders.

Dispersants

Small molecule electrolytes such as tetramethylammonium hydroxide (TMAH) and citric acid (CA) are often used. They stabilize ceramic powders mainly through electrostatic mechanisms. When adsorbed on the particle surface, they shift the isoelectric point and increase the zeta potential. This enhances electrostatic repulsion between particles.

Surface Chemical Modification

Surface chemical modification involves chemical reaction or adsorption between the modifier and surface functional groups. The modifier coats or grafts onto the particle surface. This improves the surface properties of the powder.

The main methods include graft polymerization modification and coupling agent modification. In graft polymerization, polymers are covalently bonded to the powder surface. Steric hindrance from the polymer suppresses particle agglomeration.

Thus, powder dispersion is improved. The key feature is that the polymer is synthesized during the modification process.

Silane coupling agents are the most commonly used coupling agent and are widely used as surface modifiers for ceramic powders. They offer advantages such as simplicity and effectiveness. Silane coupling agents are particularly suitable for modifying ceramic powders with hydroxyl groups on their surfaces. This is because hydroxyl groups react with silane hydrolysis products to form covalent bonds. Therefore, silane coupling agents are one of the few modifiers that can chemically react with the surface of SiC powders.

Epic Powder

Epic Powder provides advanced solutions for silicon carbide powder surface modification. Using three roller mill modifier, pin mill modifier, and turbo mill modifier, we deliver precise and efficient coating results. These technologies ensure excellent dispersion and stability of SiC powders. With Epic Powder’s equipment, customers achieve improved forming performance and higher-quality ceramic products.