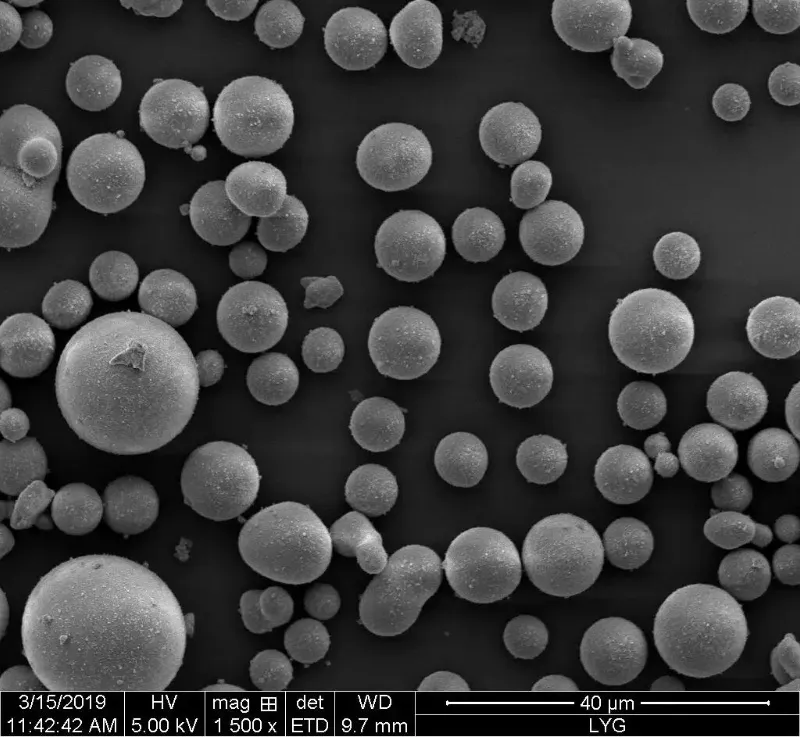

With the rapid development of modern industry and technology, the performance requirements for powder materials in different sectors have become increasingly stringent. In addition to low impurity content, fine particle size, and narrow particle size distribution, powders are also required to have specific particle morphologies. Spherical powder, due to their superior flowability and uniformity, are widely used in reinforced materials, coatings, ceramics, and 3D printing.

Advantages of Spherical Powders

Compared with irregular powders, spherical powders exhibit remarkable advantages, mainly in the following aspects:

- Spherical powders have a regular surface morphology with fewer defects, which reduces mold wear during processing into final products.

- Their particle size distribution is narrow and more uniform.

- They show excellent flowability, which improves packing density and significantly enhances the compactness of formed parts in powder metallurgy.

- During sintering, they shrink more uniformly, making it easier to control grain size effectively.

Application Characteristics

Because of their excellent surface morphology, particle size distribution, and flowability, spherical powders are widely used in high-end industries. For example:

- Spherical silica micropowder is widely used in high-end industries such as ultra-large-scale integrated circuit packaging and the electronic information field due to its outstanding insulation and heat resistance;

- Spherical titanium powder and its alloys stand out in advanced powder metallurgy, laser additive manufacturing, and thermal spraying thanks to their high sphericity, good flowability, high tap density, low oxygen content (<0.15 wt%), and fine particle size;

- Spherical tungsten powder offers excellent flowability, high bulk and tap densities, and low oxygen content, making it highly valuable in cathode emission, porous materials, and ultrafine hard alloys.

Spherical Powder Preparation Technologies

Spherical powder processing is an indispensable part of modern industry and technology. It improves surface properties and physical performance, enhances manufacturing precision and efficiency, optimizes material functionality, reduces energy consumption, and promotes green manufacturing.

Currently, spherical powder preparation methods mainly include:

- Traditional physical methods (mechanical shaping, spray drying)

- Chemical methods (gas-phase chemical reactions, precipitation, hydrothermal synthesis, sol-gel, and microemulsion)

- High-temperature fusion methods (plasma spheroidization, atomization, combustion flame spheroidization)

Comparative Analysis of Spherical Powder Technologies

| Spherical powder preparation method | Environmental protection | Product purity | Cost | Process complexity | |

| Physical method | Mechanical shaping method | High | Low | Low | Simple |

| Physical method | Spray method | General | Affected by the quality of raw materials and solvents | Higher | More Complex |

| Chemical Method | Gas-phase chemical reaction method | General | Affected by reaction conditions and raw material quality | Higher | More Complex |

| Chemical Method | Precipitation method | General | Affected by reaction conditions and raw material quality | Lower | Simple |

| Chemical Method | Sol-gel method | Higher | Affected by reaction conditions and raw material quality | Lower | Simple |

| Chemical Method | Microemulsion method | General | High | Lower | Simple |

| Chemical Method | Hydrothermal method | Higher | High | Lower | Simple |

| High-temperature melting method | Plasma spheroidization method | Higher | High | Higher | More complex |

| High-temperature melting method | Atomization method | Higher | High | Lower | Simple |

| High-temperature melting method | Gas combustion flame spheroidization method | Higher | Affected by raw materials, gas mixture ratio, temperature, etc. | Higher | More complex |

Traditional physical methods

Traditional physical methods use widely available and low-cost raw materials with industrialization potential, but they demand high equipment standards and often fail to guarantee stable particle characteristics. They are mainly suitable for products with lower quality requirements. Future improvements may involve automation and intelligent manufacturing technologies, such as advanced control systems, machine learning, and artificial intelligence.

Chemical methods

Chemical methods can achieve uniform particle size and high purity but usually require large amounts of chemical agents (e.g., surfactants, precipitants). These processes often face challenges in removing organic impurities and preventing agglomeration, making large-scale industrialization difficult.

High-temperature fusion methods

High-temperature fusion methods are suitable for high-melting-point powders but require precise temperature field control. Additionally, harmful by-products may be generated during melting, posing environmental challenges. Future developments should focus on eco-friendly, sustainable technologies that minimize waste and use greener raw materials, aligning with global trends in green manufacturing.

Conclusion

In summary, each spheroidization method has its advantages and disadvantages. The choice of method depends on factors such as application requirements, energy consumption, material properties, and cost. Proper process control and equipment optimization are essential to ensure environmental sustainability, product purity, and cost-effectiveness.