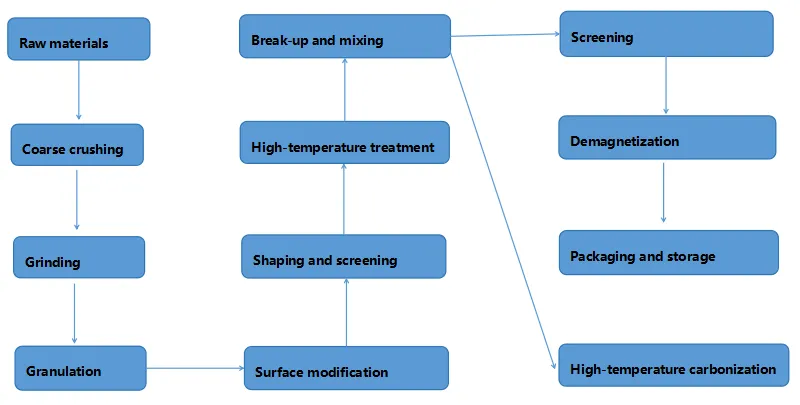

The production of artificial graphite anode materials involves multiple key processes. These processes are closely linked and mutually influential, collectively determining the performance and quality of the final product. The following is a brief overview of the main processes:

| Serial Number | Process Name | Main Function |

| 1 | Raw Material Inspection | Ensure that incoming materials meet quality standards and control product quality from the source. |

| 2 | Coarse Crushing | Crush bulk raw materials to the specified size for uniform subsequent feeding. |

| 3 | Pulverization | Achieve ultrafine grinding of materials and control particle size distribution, which impacts battery cell performance. |

| 4 | Shaping | Control material particle size distribution, modify morphology, and increase powder tap density. |

| 5 | Mixing | Mix graphite materials with asphalt in appropriate proportions to prepare for the granulation process. |

| 6 | Coating and Granulation | Produce composite secondary particles, improving multiple product performance indicators. |

| 7 | Pre-Carbonization | Increase the carbon purity of the negative electrode material and optimize the loading amount for subsequent processes. |

| 8 | Graphitization | High-temperature heat treatment improves the microstructure and enhances conductivity and other properties. |

| 9 | High-Temperature Carbonization | Repair graphite surface defects to improve rate and fast charging performance. |

Detailed Process Description

Raw Material Inspection

Objective: To conduct strict inspections of raw materials (such as petroleum coke, pitch coke, bitumen, etc.), ensuring they meet established quality standards and provide a solid foundation for subsequent production.

Key Steps: Perform comprehensive tests on chemical composition, physical properties, and other relevant indicators based on applicable standards and inspection norms.

Quality Control: Accurate records of test results should be maintained. A complete raw material quality file must be created to ensure traceability during production.

Coarse Crushing

Objective: To crush large raw materials (such as petroleum coke, pitch coke, etc.) into particles of specified size or mesh, facilitating uniform feeding in subsequent processes.

Key Steps: Choose the appropriate crushing equipment and process parameters based on material characteristics and product requirements. Ensure stable crushing performance to avoid over-large or over-small particles.

Quality Control: Use screening or other methods to check the particle size distribution of the crushed material. Non-conforming materials should be reprocessed.

Grinding

Objective: To ultrafinely grind materials to the required particle size distribution, reducing from millimeter-scale to micron-scale particles, typically achieving a finished size of 5-75μm, to meet battery performance requirements.

Key Steps: Precisely control particle size and morphology based on product performance indicators. Select appropriate grinding equipment (such as air jet mills) and optimize process parameters to achieve the desired results.

Quality Control: Use particle size analyzers to monitor the particle size distribution after grinding. Ensure smooth material surfaces and reasonable specific surface area, improving the anode’s specific capacity, rate, and low-temperature performance.

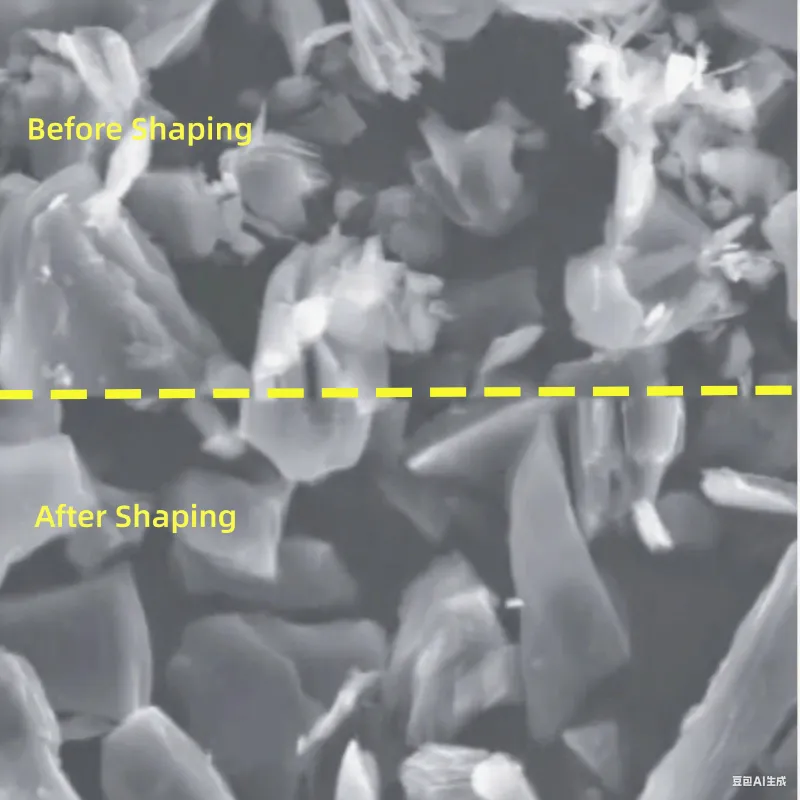

Shaping

Objective: Control the content of fine and coarse powders, improve the particle size distribution, increase tap density, and modify the morphology of the material to reduce the specific surface area and optimize product performance.

Key Steps: Adjust shaping equipment parameters according to material characteristics and required particle size distribution. Ensure stable shaping effects.

Quality Control: Check the particle size distribution concentration and morphology after shaping. Non-conforming materials should undergo rework.

Mixing

Objective: To mix shaped graphite material and ground bitumen in a specific ratio, ensuring uniform bitumen coverage on the graphite surface. This step creates favorable conditions for granulation and improves multiple product performance indicators.

Key Steps: Accurately weigh graphite and bitumen according to the product formula. Use appropriate mixing equipment and optimize mixing parameters to ensure uniformity.

Quality Control: Take samples to test the uniformity of the mixture. Check the bitumen coating effect to ensure it meets granulation requirements. Non-conforming materials should be re-mixed.

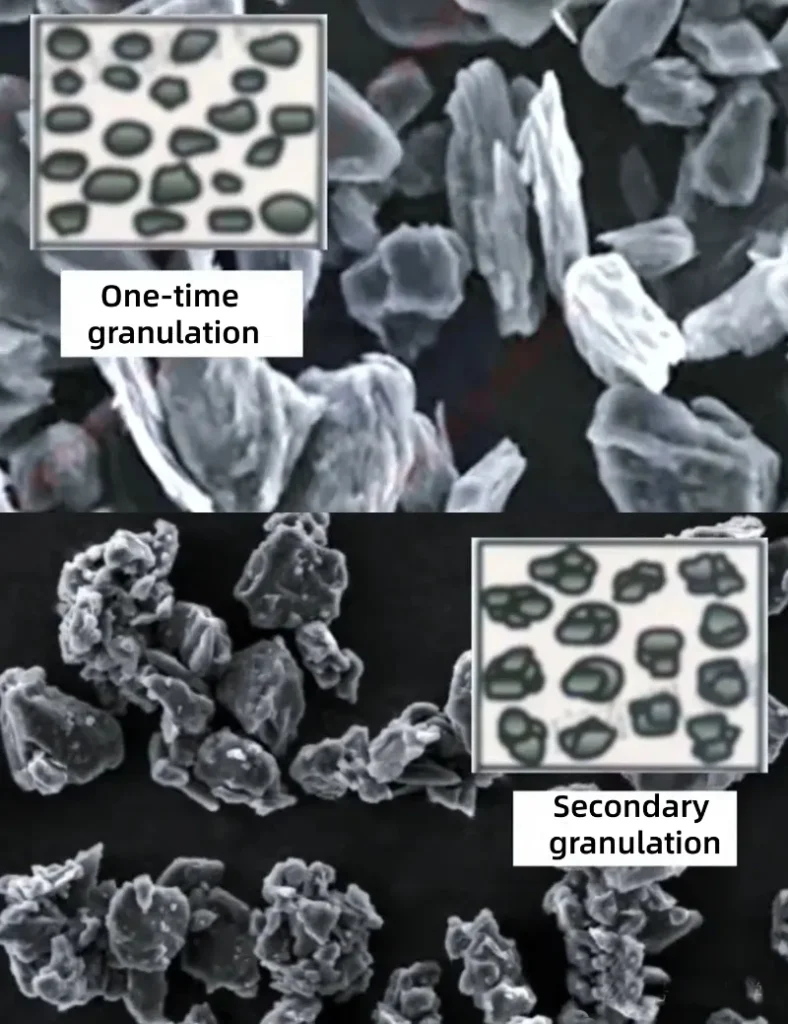

Coating and Granulation

Objective: Add raw materials and bitumen into a reactor for high-temperature stirring. This process forms secondary particles by coating the graphite particles, enhancing lithium-ion embedding and extraction channels and forming a protective layer on the surface to reduce solvent co-embedding reactions.

Key Steps: Control the reactor’s temperature, stirring speed, and other parameters precisely to ensure stable granulation.

Quality Control: Inspect particle size distribution, secondary particle formation, and coating quality after granulation. Non-conforming materials should be reprocessed.

Pre-carbonization

Objective: Control pre-carbonization temperature (typically between 900-1200°C) to increase carbon purity and prevent “material loss,” improving capacity and energy efficiency, while reducing costs.

Key Steps: Strictly control pre-carbonization temperature, time, and other parameters to ensure optimal pre-carbonization results.

Quality Control: Test carbon purity, microstructure, and other indicators post-carbonization. Evaluate its impact on subsequent processes, ensuring pre-carbonization quality meets the requirements.

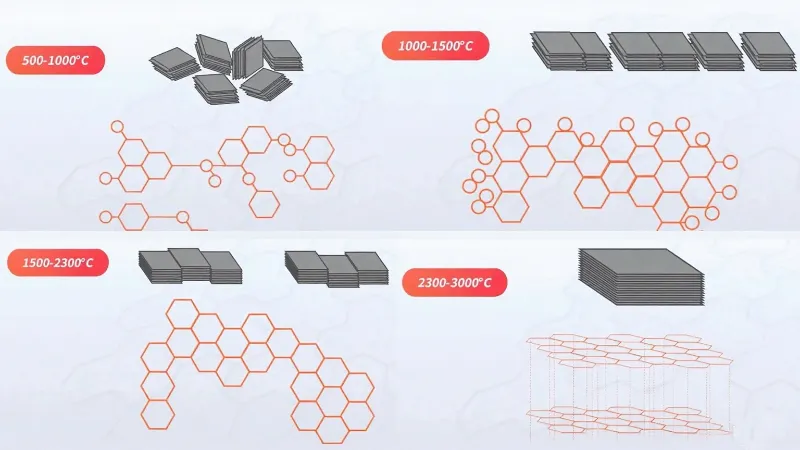

Graphitization

Objective: Place material in a graphitization furnace at around 3000°C to heat-treat the material, changing the carbon atoms’ arrangement from a planar structure to a three-dimensional ordered structure. This process improves conductivity, reduces impedance, and removes impurities.

Key Steps: Accurately control temperature, heating rate, and dwell time in the graphitization furnace to ensure uniform, stable results.

Quality Control: Use various detection methods to assess microstructure, conductivity, impurity levels, and other indicators after graphitization. Non-conforming materials should undergo reprocessing.

High-Temperature Carbonization

Objective: For 3C products and high-end applications, high-temperature carbonization is performed post-graphitization. During carbonization (at 1000-1200°C), bitumen or resin coatings on the surface repair graphite defects, reduce specific surface area, and improve performance, such as rate capability and fast-charging performance.

Key Steps: Select appropriate coating materials based on product requirements. Control temperature and time during the carbonization process to achieve the desired effect.

Quality Control: Test the surface structure and performance indicators of the carbonized material to ensure it meets high-end product requirements.

Future Development Direction of Artificial Graphite Anode Materials

Increasing energy density: By improving production processes and formulations, such as the “isotropic coke” technology, the tap density of artificial graphite is enhanced, increasing the energy density of battery cells and meeting the long-range needs of electric vehicles.

Improving fast-charging performance: Research on artificial graphite with larger interlayer spacing and suitable micropore structures for fast-charging anode materials will facilitate rapid lithium-ion insertion and charging/discharging.

Enhancing cycle stability: Develop high-structural-strength artificial graphite secondary particles. Using suitable coke aggregate size and coating methods (such as amorphous carbon or carbon nanotube coatings) will improve cycle stability and high-temperature storage performance for lithium-ion batteries.

Epic Powder

With its advanced grinding and processing technologies, Epic Powder plays a crucial role in optimizing production processes for high-performance artificial graphite. Through customized solutions such as air jet mills and other specialized equipment, Epic Powder ensures precise control over material properties, helping manufacturers achieve superior product performance, higher efficiency, and reduced costs.