Barium titanate (BaTiO₃) powder is the primary raw material of titanate-based electronic ceramics. As a typical ferroelectric material with excellent dielectric properties, it is widely used in multilayer ceramic capacitors (MLCCs), sonar devices, infrared radiation detectors, grain-boundary ceramic capacitors, and positive temperature coefficient (PTC) thermistors. With broad application prospects, barium titanate is regarded as a pillar material of electronic ceramics.

With the ongoing trend toward miniaturization, lightweight design, high reliability, and thin electronic components, the demand for high-purity and ultrafine barium titanate powder has become increasingly urgent.

Overview of Barium Titanate

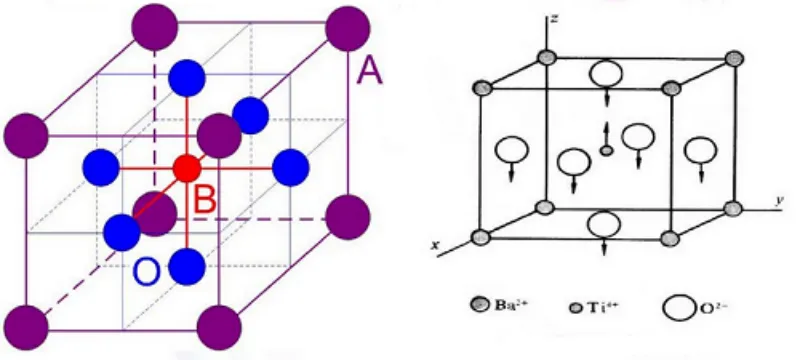

Barium titanate is a congruently melting compound with a melting point of 1618 °C. It exhibits five crystalline polymorphs: hexagonal, cubic, tetragonal, orthorhombic, and rhombohedral. At room temperature, the tetragonal phase is thermodynamically stable.

Ferroelectricity of Barium Titanate

When BaTiO₃ is subjected to a strong electric field, persistent polarization occurs below its Curie temperature of approximately 120 °C. Polarized barium titanate exhibits two key properties: ferroelectricity and piezoelectricity.

In BaTiO₃ ferroelectric crystals, numerous small regions exist in which the spontaneous polarization directions differ. Each region consists of many unit cells with the same polarization direction; these regions are known as domains. Crystals with such domain structures are referred to as ferroelectric crystals or ferroelectrics. Under an external electric field, the size and geometry of these domains change accordingly.

Curie Temperature of Barium Titanate

The Curie temperature (Tc) of BaTiO₃ refers to the phase transition temperature between the tetragonal and cubic phases, at which the ferroelectric crystal loses its spontaneous polarization and the domain structure disappears. The Curie temperature of BaTiO₃ is approximately 120 °C.

Preparation Methods of Barium Titanate Powder

The preparation methods of barium titanate powder can generally be divided into three categories: solid-state method, hydrothermal method and sol-gel method.

Solid-State Method

The solid-state method, also known as high-temperature solid-phase synthesis, is the most classical approach for preparing barium titanate powders. The basic principle involves diffusion-controlled reactions between solid raw materials at elevated temperatures.

Typically, barium carbonate (BaCO₃) and titanium dioxide (TiO₂) are mixed according to stoichiometric ratios, followed by milling and either pelletizing or loose calcination at high temperatures (usually 1100–1300 °C) for several hours to induce a solid-state reaction and form BaTiO₃ powder. The reaction is as follows:

BaCO₃ + TiO₂ → BaTiO₃ + CO₂↑

This method features simple equipment and low cost and has been widely adopted for large-scale industrial production. However, the resulting powders usually have relatively large particle sizes (micron scale) and tend to exhibit agglomeration and impurity contamination.

· Application of Grinding Equipment

- Ball Mill: Used during the batching stage to uniformly mix raw materials and reduce particle size, thereby increasing the contact area.

- Bead Mill: After calcination, barium titanate often forms hard agglomerates; horizontal bead mills are commonly used for intensive grinding to obtain micron or submicron products.

· Advantages and Disadvantages:

Low cost and high output, but prone to introducing wear-induced impurities and producing relatively coarse powders.

Hydrothermal Method

The hydrothermal method is a liquid-phase synthesis technique conducted in aqueous solutions under high temperature and high pressure, and it is widely used for preparing nanoscale barium titanate powders.

In this process, barium salts (such as barium hydroxide) and titanium salts (such as titanium chloride) are dissolved in water, with mineralizers (e.g., NaOH) added. The mixture is then reacted in a hydrothermal autoclave at 150–250 °C under high pressure for several hours, directly yielding well-crystallized BaTiO₃ powders.

This method does not require high-temperature calcination and allows precise control of particle size (typically 50–200 nm), with high crystallinity and phase purity (tetragonal or cubic). It is also environmentally friendly. However, it requires sophisticated equipment and strict control of reaction conditions.

· Application of Grinding Equipment

- Precursor Dispersion: Before autoclave treatment, vibration mills or ball mills are often used to ensure homogeneous slurry dispersion.

- Post-Treatment Deagglomeration: Although hydrothermally synthesized nanopowders have high crystallinity, soft agglomeration can occur during drying. Jet mills are commonly used at this stage. Through particle–particle collisions without grinding media, jet milling effectively breaks agglomerates while avoiding metal contamination and preserving nanoscale characteristics.

· Advantages and Disadvantages:

Extremely high purity and nanoscale particle size, making it the preferred method for high-end MLCC production.

Sol–Gel Method

The sol–gel method is a type of liquid-phase synthesis that enables powder preparation with molecular-level control. Titanium alkoxides (such as tetrabutyl titanate) and barium salts (such as barium acetate) are used as precursors. Through hydrolysis in an organic solvent, a sol is formed, which then transforms into a gel via evaporation or heating. After drying and low-temperature calcination (600–900 °C), BaTiO₃ powder is obtained.

This method produces powders with nanoscale particle size, high purity, and excellent compositional uniformity, making it suitable for high-performance electronic ceramics. However, the raw materials are expensive, and strict control of pH and temperature is required to avoid inhomogeneous precipitation.

· Application of Grinding Equipment

- Planetary Ball Mill: The dried gel obtained by the sol–gel process is extremely brittle. Short-duration dry or wet milling with a planetary ball mill is often used to obtain uniform nanopowders.

· Advantages and Disadvantages:

This method offers the best compositional uniformity, but due to high raw material costs, solvent toxicity, rapid agglomeration during heat treatment, and stringent process control requirements, it is difficult to industrialize and is currently mainly confined to laboratory research and specialized thin-film applications.

Conclusion

The three main preparation methods of barium titanate powder—solid-state, sol–gel, and hydrothermal methods—each have distinct advantages and limitations. The solid-state method is suitable for large-scale production but yields relatively coarse powders. In contrast, sol–gel and hydrothermal methods can produce nanoscale powders and are better suited for high-end electronic applications.

Grinding equipment plays an indispensable role in all these methods: it is essential for raw material mixing and particle refinement in solid-state synthesis, and it supports post-treatment dispersion in liquid-phase processes. By optimizing grinding parameters—such as grinding media materials, rotational speed, and milling time—the quality and performance of barium titanate powders can be significantly improved.

Looking ahead, with advances in milling and dispersion technologies, particularly the introduction of nanoscale grinding equipment, the preparation of barium titanate powders will become more efficient, further driving innovation in the electronic materials industry.

“Thanks for reading. I hope my article helps. Please leave a comment down below. You may also contact Zelda online customer representative for any further inquiries.”

— Posted by Emily Chen