With the increasing number of electronic devices, invisible electromagnetic waves have become a source of electromagnetic pollution, threatening information security. This is where electromagnetic wave absorbing powders in polymer materials come into play. They absorb and shield electromagnetic waves, enhancing the electromagnetic compatibility of materials and ensuring the stable operation of electronic devices. They can also improve the mechanical properties of materials, playing a significant role in areas like smartphones and aerospace. They provide an excellent solution to these challenges.

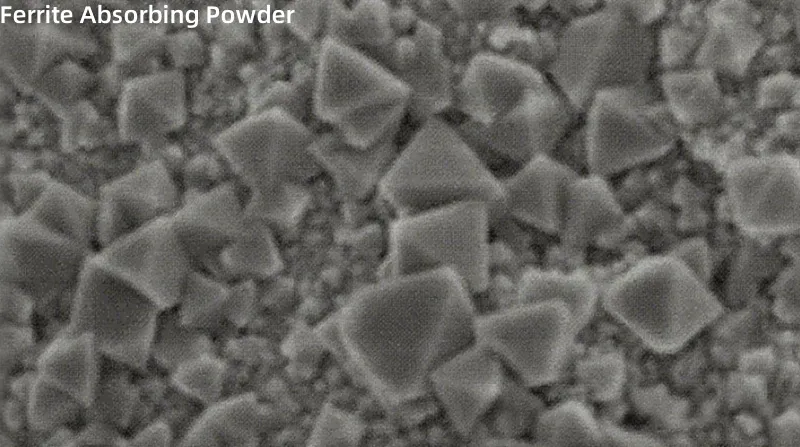

Ferrite Absorbing Powders

Ferrites are essential absorbing materials due to their high magnetic permeability and good impedance matching properties. They are widely used in polymer materials. The primary mechanisms for electromagnetic wave loss include self-polarization, hysteresis loss, domain wall resonance, and natural resonance. Ferrite’s magnetic permeability directly affects its wave-absorbing capacity; higher permeability leads to better absorption.

By ion substitution, ferrite’s electromagnetic properties can be adjusted. For example, in NiZn ferrite, modifying the ratio of Ni to Zn not only optimizes permeability but also changes how it responds to different frequencies of electromagnetic waves.

When the Ni/Zn molar ratio is 0.5, permeability peaks, leading to better wave absorption in a specific frequency range. Additionally, designing the microstructure can increase the surface area of ferrite, improving absorption efficiency. By combining with carbon materials, polymers, and MXene, a synergistic effect can be achieved to further enhance absorption performance.

Carbonyl Iron Powder (CIP)

Carbonyl iron powder has high magnetic permeability, strong temperature stability, and low cost, making it a common and excellent microwave absorber. In polymer materials, CIP can be evenly dispersed to form an absorbing network, effectively absorbing electromagnetic waves entering the material. The high magnetic permeability of CIP allows it to strongly respond to electromagnetic waves. Through mechanisms like hysteresis loss, electromagnetic wave energy is converted into heat and dissipated. The medium-pressure method for producing CIP, compared to the high-pressure method, requires lower synthesis pressure and provides higher iron conversion rates, resulting in more stable performance and better wave absorption.

Carbon Fiber (CF)

Although carbon fiber is costly and reflects electromagnetic waves, its wave absorption performance can be improved when combined with other absorbing materials. Carbon fiber itself has conductivity, which, when combined with absorbing materials, forms a conductive network that promotes electromagnetic wave conduction and loss. For example, mixing with glass fiber (GF) lowers cost and compensates for the shortcomings of individual fiber-reinforced materials. Additionally, the high strength of carbon fiber provides excellent mechanical support for composite materials, ensuring the stability of the absorbing materials in practical applications.

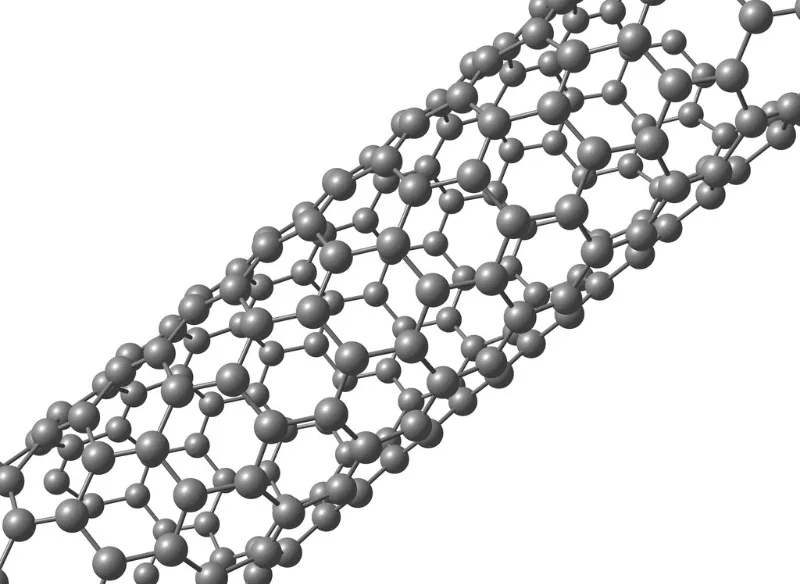

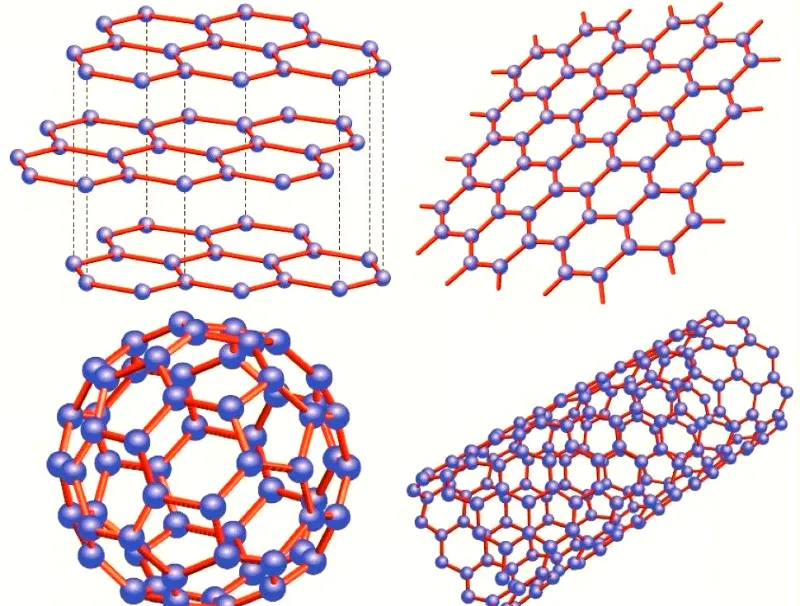

Carbon Nanotubes (CNTs)

Carbon nanotubes, due to their outstanding conductivity and unique structure, are highly potential absorbing materials in polymer systems. They can be combined with ferrite and other materials to form composites with excellent absorption properties. CNTs’ conductivity enables them to absorb electromagnetic waves via conductive loss mechanisms. When combined with materials like ferrites, which have magnetic loss properties, the combined effect of both conductive and magnetic losses enhances the overall wave absorption performance. Furthermore, the unique structure of CNTs increases their interaction with electromagnetic waves, improving absorption efficiency. When the nanotube diameter is less than 6 nm, CNTs act as excellent conductive quantum wires, significantly boosting their ability to absorb electromagnetic waves.

Graphene

Graphene, as a two-dimensional material, is known for its high conductivity and strength. It can be combined with ferrites and other absorbing materials to produce polymer composites with excellent absorption properties. Graphene’s high conductivity enables it to absorb electromagnetic waves via conductive loss. Its high thermal conductivity helps quickly convert absorbed wave energy into heat, enhancing wave absorption efficiency. Additionally, graphene’s strength provides excellent mechanical properties for composite materials.

Epic Powder

In the realm of polymer materials, the application of various absorbing powders, such as ferrites, carbonyl iron powder, carbon fiber, carbon nanotubes, and graphene, offers innovative solutions for mitigating electromagnetic interference. The production and processing of these powders require specialized equipment to ensure the desired particle size, distribution, and surface modification. Epic Powder’s grinding and powder processing equipment, such as jet mills, ball mills, and surface modification machines, are ideal for producing high-quality, fine powders that can enhance the performance of these absorbing materials. By utilizing advanced grinding and classification technologies, we can optimize the electromagnetic wave absorption capabilities of these materials, making them more effective for use in electronic devices and other high-tech industries.