1. Causes of Low Activity of Slag Powder

Many factors contribute to the low activity of slag powder. A high proportion of crystalline phases and a complete crystal structure are primary factors. Furthermore, a high content of acidic oxides like SiO2 and a low content of basic oxides like CaO further reduce activity. When analyzing What Are the Causes of Slag Powder Grinding inefficiency, chemical composition is the first hurdle.

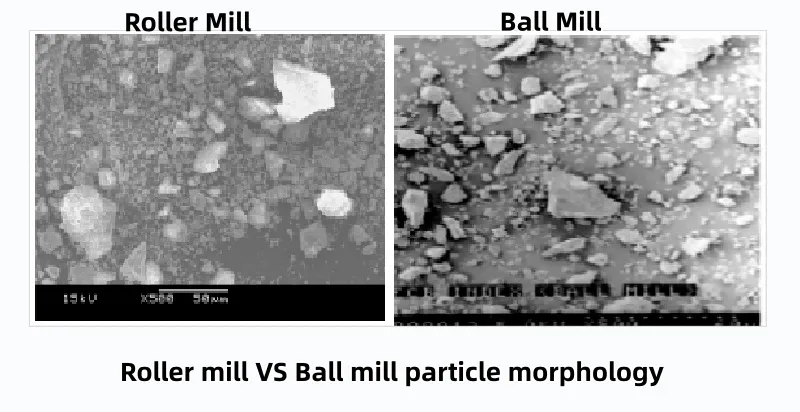

Secondly, specific surface area, particle morphology, and particle size distribution play vital roles. Specific surface area is a necessary prerequisite for activity. However, higher surface area does not always mean higher activity. Grinding equipment and processes influence activity by changing particle shapes. For optimal strength, 80%–85% of slag particles should fall within the 0–12 μm range. Additionally, more than 95% should be smaller than 30 μm.

2. Grinding Equipment and Grinding Processes

At present, the main grinding equipment used for slag powder production in China includes ball mills and vertical roller mills. Grinding equipment and grinding processes directly affect the fineness, particle morphology, and particle size distribution of slag powder. A preliminary analysis is as follows.

2.1 Ball Mill

The production process of slag powder by ball milling is divided into closed-circuit grinding systems and open-circuit grinding systems.

Closed-circuit grinding system

The power consumption of a closed-circuit ball mill slag grinding system is lower than that of an open-circuit system. Although the product fineness can be controlled to a very fine level, larger slag powder particles are still easily selected into the finished product under the action of negative pressure airflow. Since the particle sizes of slag powder are similar, this results in an unreasonable particle size distribution. The classification principle belongs to gravity classification, that is, particles are retained or removed according to their weight. A relatively large number of particles above 30 μm will enter the finished product, and these particles contribute relatively little to strength development.

Open-circuit grinding system

Most domestic slag powder producers still use ball mills with open-circuit grinding systems. Slag powder processed by ball mills contains a high proportion of fine particles with a wide size distribution, and the slag powder activity index is relatively high. When slag is ground to 480 m²/kg and the particle size distribution is relatively reasonable, most particles are distributed between 0–30 μm. For slag of the same quality, grinding with a ball mill open-circuit system results in a relatively higher activity index.

In a ball mill open-circuit system without pre-crushing equipment, power consumption is relatively high. It typically stays between 65–95 kWh/t when the surface area reaches 420 m²/kg. The internal structure of the ball mill is critical. Factors like chamber length distribution and diaphragm plate configuration directly affect the product. Additionally, grinding media grading impacts the specific surface area and particle size distribution. Together, these elements determine the final activity index of the slag powder.

During investigations, it was found that a slag powder company used an open-circuit ball mill with grinding aids, yet the slag powder activity was extremely low and the specific surface area could only reach 450 m²/kg. This ball mill had three chambers, and the third chamber used miniature steel segments with grooved liners. The third chamber is the grinding chamber and is critical for increasing specific surface area and improving activity. Configuring miniature steel segments with grooved liners in this chamber is contrary to common practice. With such a grinding method, how can the specific surface area be increased, a reasonable particle size distribution ensured, and slag powder activity improved?

2.2 Vertical Roller Mill

When using a vertical roller mill (VRM) to grind slag powder to a specific surface area of about 420 m²/kg, the mill output is high and the power consumption is about 40 kWh/t. The grinding power consumption is relatively low, making it popular among users.

Practice has proven that, for the same clinker and the same specific surface area, cement produced by a vertical mill has a 3-day compressive strength about 3 MPa lower than that produced by a ball mill. Does the same defect exist in slag powder ground by a vertical mill?

Similar to a closed-circuit ball mill system, a vertical mill is equipped with a classifier for fine powder collection. If operated improperly or if system parameters are not reasonably controlled, a considerable number of particles larger than 30 μm may be collected as finished product. This results in a narrow particle size distribution range and reduces slag powder activity. Secondly, the vertical mill grinding mechanism is shear-based, and particle morphology also affects strength development, thereby lowering the activity index.

Another often-overlooked issue is the process in which high-temperature gas directly dries slag inside the mill. In other words, the 0–12 μm fine slag particles must pass through high-temperature gas at around 250°C before entering the finished product silo. This is equivalent to subjecting water-quenched slag to high-temperature heat treatment again, promoting crystal growth and reducing defects in the slag, thereby lowering activity.

If vertical mill operation and management are well controlled, with reasonable regulation of temperature, air pressure, and airflow rate, the reduction in slag powder activity can be relatively minimized. Poor control, however, will aggravate the reduction in activity.

2.3 Horizontal Roller Mill

The horizontal roller mill features a simple process and internal structure, with fewer factors that reduce slag powder activity. After grinding, the material exhibits ideal particle morphology and particle size distribution, and the product quality is reliable. Cement ground by a horizontal roller mill has relatively high strength. When grinding steel slag powder to a specific surface area of about 460 m²/kg, the main motor power consumption is 33–35 kWh/t, making it one of the preferred pieces of equipment for slag powder grinding.

The cement particle morphology produced by a horizontal roller mill is very similar to that produced by a ball mill (see the Figure below).

3. Methods to Improve Slag Powder Activity

Main Reasons for Low Activity of Slag Micropowder

Through the above analysis, the primary reasons for the low activity of slag micropowder are the results of water-quenching treatment of the slag, as well as its chemical composition, particle morphology, particle size distribution, and operational aspects of the process.

How can suitable process measures be reasonably adopted to improve the activity of slag micropowder?

Comprehensive Influence of Specific Surface Area and Particle Characteristics on Activity

In theory, slag powder grinding must reach a specific surface area above 480 m²/kg to fully realize its activity. However, if the slag basicity is around 85%, increasing the surface area further may not help. Even when an open-circuit ball mill reaches over 500 m²/kg, the activity rarely shows significant improvement. This occurs because the activity index depends on more than just surface area. Critical factors include particle morphology and the rationality of the size distribution. These are directly induced by the specific grinding process and equipment used. Therefore, improving the activity of slag micropowder requires comprehensive technical measures.

Physical and Chemical Dual Activation as the Key to Improving Activity

To enhance the activity of slag micropowder, it is necessary to adjust the surface chemical composition of the slag micropowder under the dual action of physical and chemical activation, thereby increasing its activity.

Improving activity is possible by combining chemical and physical adjustments. First, acidic slag micropowder should be adjusted to a weakly alkaline or alkaline state. Next, the material must undergo reasonable slag powder grinding to achieve finer particle sizes. This process expands the range of the ideal particle distribution. By following these steps, the goal of significantly improving slag micropowder activity can be achieved.

Siping Cement’s Activator Technology Practice

Siping Cement has researched ways to address low activity in acidic slag. They also focused on issues caused by improper slag powder grinding processes. To promote activity improvement, they applied a combination of external liquid activators and powder activators. They also utilized physical-chemical composite activation methods. These combined strategies have already achieved initial success in improving slag micropowder performance.

When activators are added during slag powder grinding, minor changes occur in the chemical composition of the resulting slag micropowder (see Table 1).

| Excitation method | SiO2 | Al2O3 | Fe2O3 | High | MgO | pH value | Quality factor |

| Slag (without activator) | 39.18 | 14.02 | 1.39 | 39.23 | 6.75 | 0.86 | 1.53 |

| Liquid activator | 37.26 | 12.02 | 1.92 | 40.71 | 6.35 | 0.95 | 1.58 |

| Liquid activator + powder activator | 35.14 | 10.42 | 1.32 | 40.24 | 7.23 | 1.04 | 1.65 |

Table 1: Minor Changes in Chemical Composition of Slag Micropowder Ground with Activators (%).

(Note: The original text does not provide specific table data; this retains the original description.)

Acidic slag primarily features high SiO₂ content, resulting in a stable structural performance that is the main factor contributing to a low quality coefficient.

Improvement Effects of Activators on Chemical Composition and Basicity

Using 0.1% liquid activator mixed with slag for slag powder grinding, the original slag chemical composition had SiO₂ at 39.18%, which decreased to 37.26% in the resulting slag micropowder, and the basicity increased from 0.86 to 0.95.

When both liquid activator and powder activator were used simultaneously during slag powder grinding, the original SiO₂ of 39.18% dropped to 35.14% in the slag micropowder, raising the basicity to 1.04 and adjusting it to meet alkaline slag indicators.

This “alkaline slag,” when ground to a certain specific surface area through appropriate slag powder grinding and with a relatively reasonable particle size distribution, will exhibit an improved activity index.

Actual Data on Activity Index Improvement

For acidic slag with 0.1% slag liquid activator added during ball mill slag powder grinding, the 7-day activity index increased from 67.4% to 88.8%, an improvement of 31.75%; the 28-day activity index rose from 89.5% to 110.7%, an improvement of 23.7%.

Depending on variations in local raw materials and production processes, chemical activation methods can individually increase the slag micropowder activity index by about 15–25%, while composite activation methods can increase it by around 50%.

Using the above technical measures, slag micropowder with an original 7-day activity index of around 55% can be raised to over 75%; slag micropowder with an original 7-day activity index of around 70% can be raised to over 95%.

Practical Application Recommendations

To solve low activity in slag micropowder, a customized approach is essential. Engineers must formulate several technical schemes based on specific on-site equipment and raw materials. Other local conditions must also be considered during this planning phase. Laboratory tests are a critical next step. The optimal technical scheme can only be selected after obtaining 7-day and 28-day test results. This selection process ensures a high improvement in the activity index. Simultaneously, it helps keep production costs and capital investment low.

“Thanks for reading. I hope my article helps. Please leave a comment down below. You may also contact Zelda online customer representative for any further inquiries.”

— Posted by Emily Chen