Ultrafine powder (also known as ultrafine powder) usually refers to powder with a particle size below 1250 mesh (10μm). It is subdivided into micron powder, submicron powder and nano powder. When solid matter is crushed to micron or even nanometer scale, its physical and chemical properties will change significantly. This makes ultrafine powder a hot topic in scientific research and industrial applications. Ultrafine powder plays a key role in modern industries. It is widely applied in electronics, light industry, chemicals, military, traditional medicine, agriculture, and food. These powders drive industrial and technological progress. Accurate analysis of ultrafine powder characterization, such as particle size, shape, distribution, and surface properties is essential. It directly affects R&D efficiency and process optimization. Mastering ultrafine powder characterization methods ensures strong technical support for both research and production.

Main Characterization Methods

Currently, the ultrafine powder characterization includes particle size analysis, determination of specific surface area, characterization of chemical composition and physical structure, and characterization of agglomerates.

Dynamics Analysis

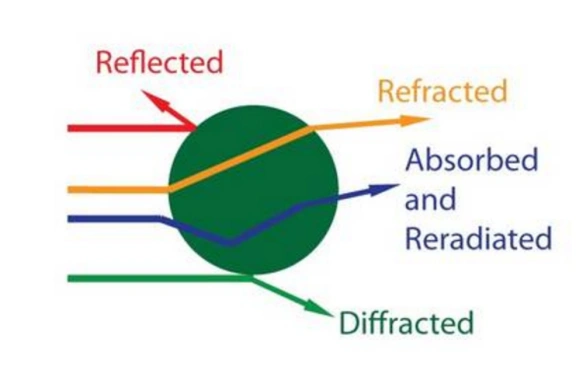

Particle size refers to the size of the material after fine dispersion. The main methods that can be used for ultrafine powder particle size analysis are: laser diffraction scattering method, sedimentation method, resistance method and electron microscopy method, as well as X-ray diffraction line width method.

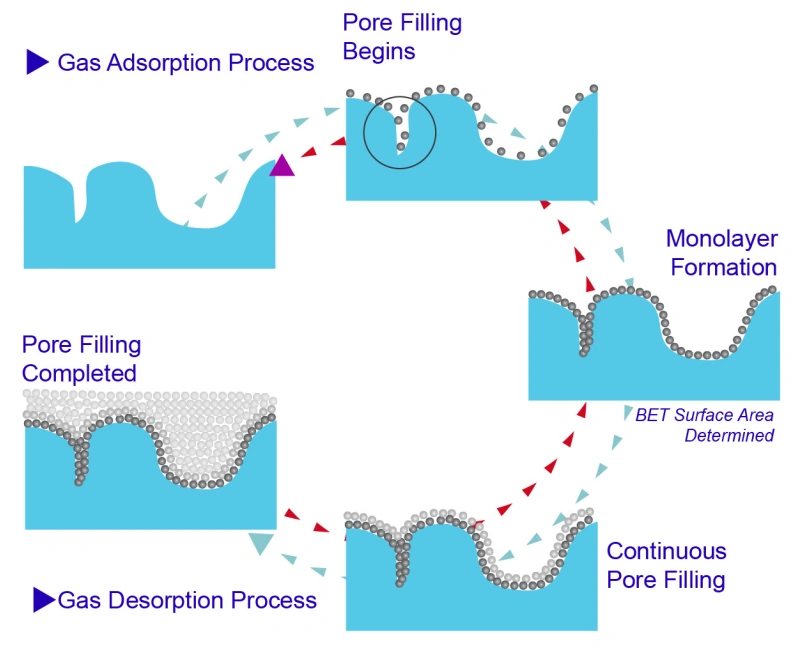

Specific Surface Area Measurement

In the preparation of finely dispersed materials, as the particle size becomes smaller and smaller, more and more particle surfaces are formed. This causes a huge change in surface energy, and the concept of specific surface area is used to link the particle surface area with the particle size. That is: volume specific surface area = total particle surface area/total particle volume. Mass specific surface area = total particle surface area/total particle mass. In practical applications, the specific surface area of powders can be measured by adsorption method, immersion heat method and permeation method. Which method to adopt depends on the measurement requirements and conditions such as materials and equipment.

Chemical Composition and Physical Structure Characterization

Classic chemical analysis methods are accurate, but are limited by powder materials with good chemical stability. In contrast, instrumental analysis shows unique advantages. The advantages of scanning electron microscopes are large depth of field, three-dimensional images, and high magnification. In addition, sample preparation is simple and the electronic damage to the sample is small. The surface composition of the sample can be directly detected and the chemical composition of the micro-area can be analyzed. X-ray polycrystalline diffraction aids phase analysis. It solves the limitation of chemical and atomic spectroscopy methods. These traditional methods detect elements but not their phases. X-ray diffraction reveals the actual phases present in the sample.

Agglomerate Characterization

The properties of agglomerates can be divided into the size, shape, distribution, and content of agglomerates. The porosity, pore size, and distribution of agglomerates. The density, internal microstructure, and strength of agglomerates. The bonding properties between primary particles within agglomerates, etc. The commonly used methods for agglomerate characterization are traditional microstructure observation, embryo density-pressure method, and mercury intrusion method, etc. In addition, there are also emerging technologies such as low-field nuclear magnetic resonance method.

Conclusion

The characteristics of ultrafine powders largely determine their performance in various fields. Therefore, accurate characterization of particle size, specific surface area, chemical composition, physical structure and agglomeration state is essential. Different methods have their own advantages and limitations. Choosing the right characterization method requires comprehensive consideration of the properties of the powder, application requirements and test conditions. In the future, with the advancement of science and technology, the accuracy, speed and automation level of characterization methods will continue to improve. This will provide more reliable technical support for the research and application of ultrafine powders. It will also further promote the development and innovation of related industries.