PMMA microspheres are tiny spheres made of polymethyl methacrylate (PMMA). PMMA is a thermoplastic (also as known as acrylic or plexiglass) with high transparency, good processing performance, strong weather resistance and excellent chemical stability, and is widely used in many fields.

Preparation Method of PMMA Microspheres

Emulsion Polymerization

Under the action of the emulsifier, the monomer is dispersed in the water phase to form an emulsion. Then the polymerization reaction is carried out under the action of the initiator. In the emulsion polymerization of MMA, the emulsifier molecules form micelles in the water phase. The monomer is dissolved in the micelles, and the initiator decomposes in the water phase to produce free radicals, which enter the micelles to initiate the polymerization of the monomers. This scheme has a fast polymerization reaction rate and the reaction temperature is easy to control. The product has a small particle size and good dispersibility, but the process is relatively complicated.

Suspension Polymerization

The water-insoluble monomer is suspended in water as small droplets. Polymerization occurs under the action of an initiator. In suspension polymerization of MMA, the monomer is dispersed into small droplets by stirring. These droplets are suspended in water containing a dispersant. The initiator is dissolved in the monomer droplets, which initiates the polymerization of the monomer inside the droplets. This method allows easy control of reaction temperature. So the product has stable quality and simple post-processing. However, a small amount of dispersant may remain in the product. This can affect the product’s transparency and electrical properties. Additionally, the process consumes a large amount of water, which creates challenges for wastewater treatment.

Application Areas

PMMA microspheres, as a special form of PMMA material, have the characteristics of uniform particle size and narrow particle size distribution. The diameter of these microspheres is usually between a few microns and tens of microns, and they have a highly uniform particle size distribution. This enables them to exhibit unique performance in various applications.

Pharmaceutical Field

Intraocular Lenses: One of the most famous medical applications of PMMA is in the field of ophthalmology, especially in the manufacture of intraocular lenses. Intraocular lenses (IOLs) are implants used to replace natural lenses after cataract surgery. PMMA intraocular lenses are usually made of PMMA materials with extremely high light transmittance and are biocompatible, allowing them to remain in the eye for a long time without causing adverse reactions.

Dental Applications: PMMA is also very important in the dental field, mainly used to make dentures, crowns, bridges, etc. Dental Restoration Materials: PMMA is a common dental restoration material, especially for making temporary crowns and bridges. It can be quickly molded, has good transparency and has a certain mechanical strength. Temporary Restoration: PMMA is often used to make temporary dentures or temporary crowns because it is easy to process and has sufficient mechanical strength to be used while the patient is waiting for permanent restoration. Long-term Applications: PMMA can also be compounded with other materials (such as ceramic materials). It is used as a long-term implanted tooth restoration material with good biocompatibility.

Orthopedic Implants

Bone Cement: PMMA is commonly used in joint replacement and spinal surgeries as a fixation material.

It is formed by mixing two components—liquid and powder—to create a high-strength adhesive.

This adhesive securely anchors artificial joints or implants to the bone.

PMMA offers good adhesion and mechanical strength, effectively enhancing the bond between the implant and the bone.

Architecture and Decoration

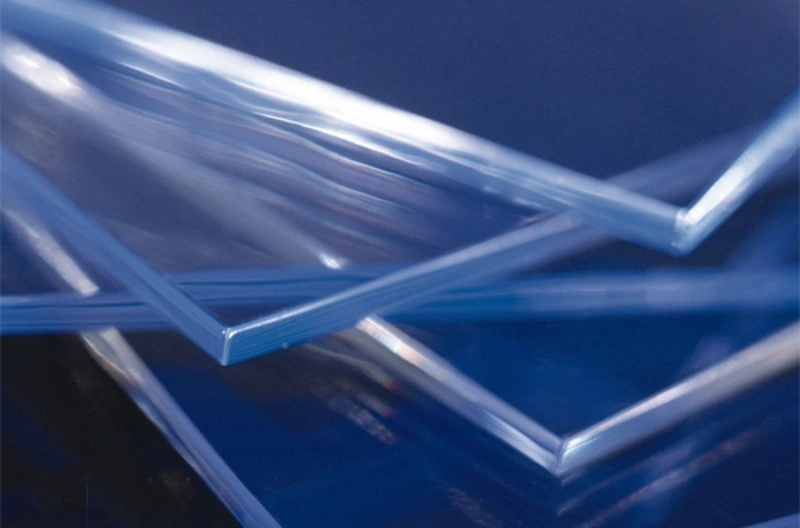

The application of PMMA-based plexiglass acrylic in the construction industry is in the construction aspect. Plexiglass acrylic is mainly used in building lighting, transparent roofs, sheds, telephone booths, stairs and room wall panels. It can also be used as sanitary ware such as bathtubs, washbasins, dressing tables and other products, and the market prospects are very broad.

Building curtain walls and windows: PMMA is often used in curtain walls and window systems of buildings, especially in occasions where large areas of lighting are required or light weight is required. PMMA can produce transparent sheets that are lighter than ordinary glass, and have strong weather resistance and are not easy to turn yellow.

Skylights and roofs: PMMA sheets are widely used in the production of skylights, roofs and lighting windows. It can effectively provide natural lighting, and at the same time has good weather resistance and is not easily affected by ultraviolet rays and aged.

Billboards and signs: PMMA has good transparency and excellent light transmittance. It is often used to make billboards, signs and signs, especially outdoor advertisements and traffic signs.

Automotive Industry

PMMA is widely used in the production of automotive headlamp covers, tail lights, and turn signal lenses . Its high transparency and excellent UV resistance make it an ideal material. It can withstand prolonged exposure to sunlight without aging. PMMA is also used to manufacture transparent covers for car dashboards. These covers offer clear visibility and strong scratch resistance. In some lightweight vehicles and concept cars, PMMA is used as a substitute for windows and windshields. This is because PMMA is lighter than conventional glass and helps reduce the overall weight of the vehicle. Its popularity is mainly due to its high light transmittance, good UV resistance, excellent impact strength, and scratch resistance.

Home Appliances and Electronic Products

PMMA is commonly used in the manufacturing of TV display panels, especially in LCDs, where it serves as optical panels and backlight components. It is also used in LED lamp covers and lighting housings. Thanks to its high transparency, UV resistance, and strong impact strength, PMMA helps extend the lifespan of lighting products. PMMA is widely applied in the housings of home appliances such as refrigerators, washing machines, and microwave ovens. Its excellent appearance and high durability make it a preferred material for these applications.

Future Prospects of PMMA Microspheres

With the continuous advancement of technology, the research and application of PMMA microspheres are developing towards greater diversification and refinement. In terms of preparation methods, researchers are exploring new techniques such as microfluidics and template methods to achieve more precise control over the particle size, morphology, and performance of PMMA microspheres. These new methods are expected to produce PMMA microspheres with narrower particle size distribution and enhanced performance, meeting the demands of high-end applications.