In today’s consumer electronics market, there is an increasing demand from consumers for lightweight and long-lasting products. From smartphones to wearable devices, products that are both slim and portable with long battery life are highly favored. The emergence of silicon-carbon anode materials has brought new hope to meet this demand and is gradually becoming a key driving force in the innovation of battery technology in the consumer electronics field.

Characteristics and Advantages of Silicon-carbon Anode Materials

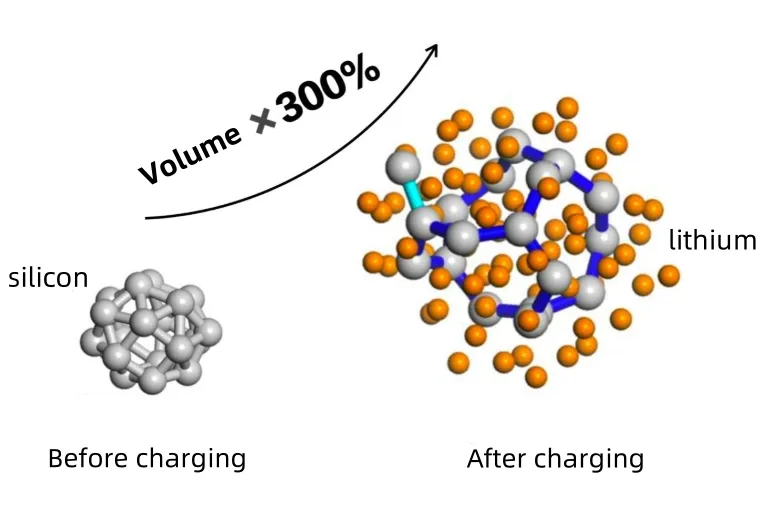

Silicon-carbon anode materials combine the advantages of both silicon and carbon. Silicon is a highly promising anode material. It has an impressive theoretical specific capacity of up to 4200mAh/g. This is more than 10 times that of traditional graphite anode materials (372mAh/g). This means that, for the same mass, silicon-based anodes can store more lithium ions. This results in higher energy density for the battery.

However, a significant issue with silicon is its high volumetric expansion during charge and discharge cycles. The expansion can reach up to 300%. This expansion is similar to the cracking of a balloon after repeated inflation and deflation. It causes the collapse of the electrode structure. This severely impacts the cycle life and stability of the battery.

The addition of carbon materials addresses this problem. Carbon materials have high electrical conductivity. This compensates for the poor conductivity of silicon. It ensures smooth current conduction within the battery. Carbon materials also have a stable structure. Their volume expansion is minimal during cycling, usually less than 10%. Carbon materials have excellent flexibility and lubricating properties. This allows them to form a buffering layer around the silicon particles. This layer absorbs the stress caused by volume expansion during charge and discharge.

By combining silicon with carbon, silicon-carbon anode materials retain the high specific capacity of silicon. They also leverage the benefits of carbon to suppress silicon’s volumetric expansion. This makes them an ideal choice for enhancing battery performance.

Application Examples of Silicon-carbon Anodes

Many smartphone manufacturers have applied silicon-carbon anode technology to their products to achieve a dual breakthrough in slimness and battery life. For example, a certain brand’s smartphone is equipped with a silicon-carbon anode battery that, with a super-thin battery thickness of just 1.9mm, achieves a large capacity of 5600mAh. This technology reconstructs the anode structure through nanomaterial processes, fully leveraging the inherent advantage of silicon’s high theoretical specific capacity, significantly improving the battery’s energy density. While maintaining the slim form of foldable devices, it effectively breaks through the battery life limitations.

Wearable devices have even stricter requirements for slimness and long battery life. Taking smartwatches as an example, traditional battery technologies struggle to provide enough power in the limited space to support all-day device operation. The application of silicon-carbon anode materials has changed this situation. After adopting silicon-carbon anode batteries, some smartwatches have extended their battery life from the original 1-2 days to 3-5 days, while maintaining a slim dial design. This allows users to avoid frequent recharging, greatly enhancing convenience. At the same time, the high energy density of silicon-carbon anode batteries makes it possible to add more functionality to smartwatches, such as more advanced health monitoring features.

Technical Challenges and Solution

Technical Challenges

Despite the many advantages of silicon-carbon anode materials, several technical challenges remain in their practical application. First, the issue of high volumetric expansion in silicon-carbon anodes has been partially alleviated by the carbon composite. However, it has not been fully resolved. During long-term charge and discharge cycles, the volume change of silicon may still cause the detachment and pulverization of the electrode material. This negatively impacts the battery’s lifespan.

Second, the preparation process for silicon-carbon anode materials is complex and costly. The mainstream chemical vapor deposition (CVD) method significantly enhances material performance. However, the expensive equipment and stringent process conditions result in high production costs for silicon-carbon anode products.

Moreover, the compatibility of silicon-carbon anode materials with electrolytes is crucial. Incompatible electrolytes can lead to side reactions. This can reduce the battery’s performance.

Solution

In order to solve the high volumetric expansion issue of silicon-carbon anodes, researchers and companies are continuously exploring new technological approaches. For example, by optimizing the design of the carbon coating layer, a composite layer is constructed on the surface of nanosilicon particles. This layer combines flexibility and ionic conductivity.

In terms of cost reduction, companies achieve this through large-scale production and process improvements.

To address the electrolyte compatibility issue, it is essential to develop specialized electrolyte formulations for silicon-carbon anodes. By adjusting the composition and additives, the electrolyte’s compatibility with silicon-carbon anodes can be enhanced. This reduces side reactions and improves the overall performance and stability of the battery.

Future Trends

With continuous technological advancements and improvements, the prospects for silicon-carbon anodes in the lightweight applications of consumer electronics are vast. On one hand, the performance of silicon-carbon anode materials will continue to improve, with the proportion of silicon doping expected to increase, enabling even higher energy density. This will allow consumer electronics to maintain a slim appearance while providing longer-lasting battery life.

On the other hand, as market demand grows and large-scale production is pushed forward, the cost of silicon-carbon anode materials will decrease, allowing for their widespread use in mid- to low-end consumer electronics. This will further expand their market share.

Epic Powder

Epic Powder, 20+ years of work experience in the ultrafine powder industry. Actively promote the future development of ultra-fine powder, focusing on crushing, grinding, classifying and modification process of ultra-fine powder. Contact us for a free consultation and customized solutions! Our expert team is dedicated to providing high-quality products and services to maximize the value of your powder processing. Epic Powder—Your Trusted Powder Processing Expert !