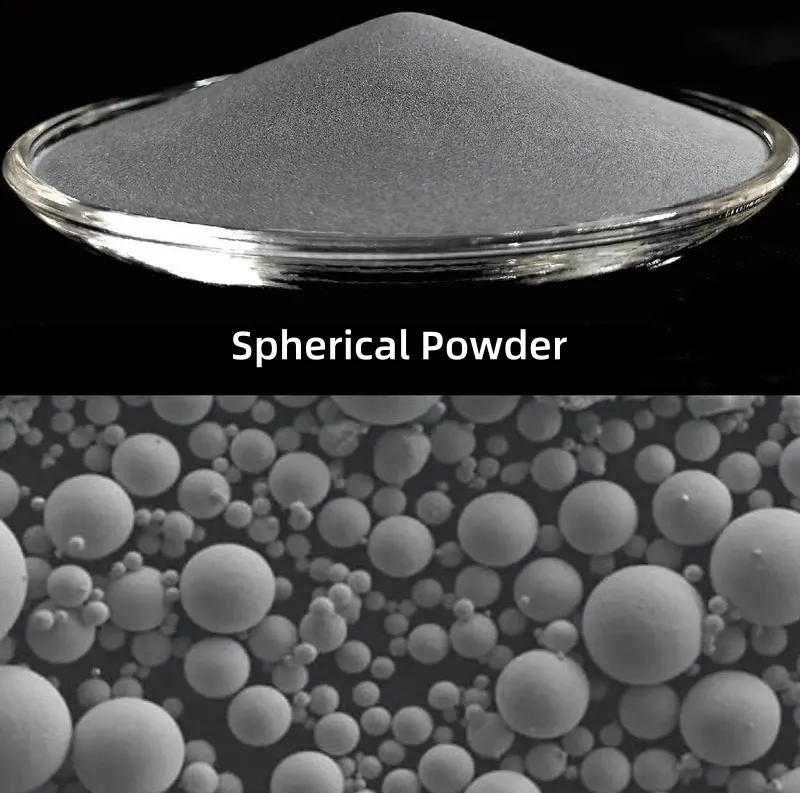

With the rapid development of modern industry and advanced technologies, performance requirements for powder materials are becoming increasingly stringent. Materials must exhibit ultra-low impurity levels, fine particle size, and a narrow particle size distribution. Particle morphology has also become a critical quality indicator. Spherical powder stands out for its uniform particle size, smooth surface characteristics, and excellent flowability. Because of these advantages, spherical powder is now widely used in high-end industrial applications.

Compared with irregular powders, spherical powders exhibit clear advantages. Their regular morphology and fewer surface defects significantly reduce mold wear during processing. Spherical powders typically show a narrower and more uniform particle size distribution. Their excellent flowability improves packing efficiency, which is especially beneficial in powder metallurgy, where it can substantially increase the density of formed parts. During sintering, spherical powders shrink more uniformly, making grain size control easier and more reliable.

Spherical Graphite

The spheroidization of natural graphite is mainly achieved by mechanically shaping natural graphite particles to obtain spherical or near-spherical morphologies. Due to its low cost, abundant resources, and suitable charge–discharge characteristics, natural graphite occupies an important position in the anode material market. However, its relatively low reversible capacity and poor cycling stability limit its further application in lithium-ion batteries.

Extensive studies have shown that converting natural graphite into spherical or quasi-spherical particles can significantly improve its electrochemical performance. Spherical natural graphite features a lower specific surface area and higher tap density, resulting in higher initial coulombic efficiency, greater reversible capacity, and superior cycling stability. As a result, it is now widely used as an anode material for lithium-ion batteries.

Spherical Silicon Micropowder

Spherical silicon micropowder exhibits excellent particle morphology, high chemical purity, and low radioactive element content. Its use can significantly reduce the coefficient of thermal expansion of epoxy molding compounds and improve their thermal stability, making it an essential filler in integrated circuit packaging.

Spherical silicon micropowder is mainly produced through methods such as high-temperature plasma melting, molten spray processes, gas flame combustion, vapor-phase synthesis, and precipitation.

Spherical Refractory Metal Powders

Refractory metals are defined as metals with melting points above 1650 °C and practical reserves, including tungsten, titanium, and molybdenum. These materials are widely used in aerospace, thermal spray coatings, additive manufacturing (3D printing), and biomedical applications.

Compared with conventional metal powders, spherical metal powders offer higher sphericity, better flowability, and higher apparent density, making them increasingly important in advanced materials science. However, the availability of high-performance spherical refractory metal powders remains a key bottleneck for the industry.

Traditional production methods often result in low spheroidization rates, severe agglomeration, and easy oxidation. In contrast, radio-frequency plasma processing significantly improves powder flowability, tap density, apparent density, and spheroidization rate. In the future, improving powder performance, reducing environmental impact, lowering plasma processing costs, and promoting large-scale industrialization will be the main development directions.

Spherical Metal Oxide Powders

Spherical Magnesium Oxide

The application performance of magnesium oxide products is closely related to the morphology and size of the raw powder. Among various particle shapes, spherical MgO particles exhibit regular morphology, high uniformity, relatively large specific surface area, and excellent sphericity. These features significantly enhance adsorption, thermal conductivity, and catalytic performance.

In thermal management materials, spherical magnesium oxide provides higher packing density. When compounded with PVC, it enables materials with higher thermal conductivity.

Spherical Alumina

Alumina is a high-performance chemical material. It can be prepared using various methods, including ball milling, plasma processing, hydrolysis, sol–gel synthesis, precipitation, and hydrothermal techniques. These methods produce alumina powders with different morphologies, such as rod-like, tubular, plate-like, fibrous, spindle-shaped, and spherical forms.

Among these, spherical alumina powders stand out due to their unique morphology. They offer excellent flowability, high specific surface area, and high bulk density. As a result, spherical alumina delivers outstanding performance in electronics, chemical processing, and defense industries. Key advantages include corrosion resistance, high-temperature stability, resistance to acids and alkalis, wear resistance, oxidation resistance, high hardness, and easy dispersion.

Grinding and Shaping Technologies for Spherical Powder Preparation

The production of spherical powders does not rely solely on chemical or high-temperature melting methods. At an industrial scale, physical preparation routes based on mechanical grinding, shaping, and classification have become mainstream due to their continuous operation, controllable costs, and wide applicability. These methods are particularly suitable for spherical graphite, spherical alumina, and spherical silicon micropowders.

During grinding, particles undergo intense shear, collision, and friction under high-speed rotation or high-velocity airflow. Sharp edges are gradually removed, and flake-like, needle-like, or irregular particles evolve toward equiaxed shapes. By precisely controlling energy input, residence time, and classification cut size, it is possible to achieve “shaping without over-grinding,” which is the key to successful spherical powder production.

Common spheroidization equipment includes:

- Air Classifier Mills (ACM): Integrated grinding and classification, ideal for materials requiring high sphericity and tight particle size distribution, such as spherical graphite and alumina

- Ball Mill + Air Classifier Systems: Gentle shaping through low-impact, high-shear action, suitable for large-scale continuous production

- Opposed Jet Mills / Flat Jet Mills: Particle–particle self-grinding mechanism with low contamination, ideal for high-purity powders

- Shape Modifiers: Dedicated post-processing equipment to improve spheroidization rate, tap density, and flowability

Through the synergistic combination of grinding, precision classification, and surface modification, spherical powders can achieve higher sphericity. Tap density is significantly improved. Specific surface area is effectively reduced. Flowability and dispersion are also enhanced. These advantages meet the demanding requirements of lithium batteries, electronic packaging, thermal management materials, and additive manufacturing.

Conclusion:

The Value Upgrade of Spherical Powders Depends on the Deep Integration of Equipment and Process Expertise

From spherical graphite to spherical alumina, and from silicon micropowder to refractory metal powders, becoming spherical is not merely a change in shape. It represents a comprehensive upgrade in performance, application potential, and product value. This transformation is supported by reliable grinding and shaping technologies. It is also driven by extensive engineering experience.

Epic Powder has been deeply engaged in ultrafine powder grinding, classification, and shaping for more than 20 years. Solutions are tailored to specific material characteristics. Customized spherical powder production systems are provided, from laboratory testing to full-scale industrial manufacturing. High-efficiency grinding equipment and precise classification control ensure higher spheroidization rates. They also deliver superior bulk density and stable product consistency. In this way, small powders truly unlock the great value of advanced materials.

“Thanks for reading. I hope my article helps. Please leave a comment down below. You may also contact Zelda online customer representative for any further inquiries”

— Posted by Emily Chen